Wet-type carbon-carbon friction material, friction element and manufacturing method

A friction material and friction element technology, applied in chemical instruments and methods, friction linings, adhesive types, etc., can solve the problems of large friction coefficient decline, large friction coefficient fluctuation, poor overload resistance, etc., and achieve high energy Effect of absorption and power absorption capacity, good thermal and chemical stability, stable coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

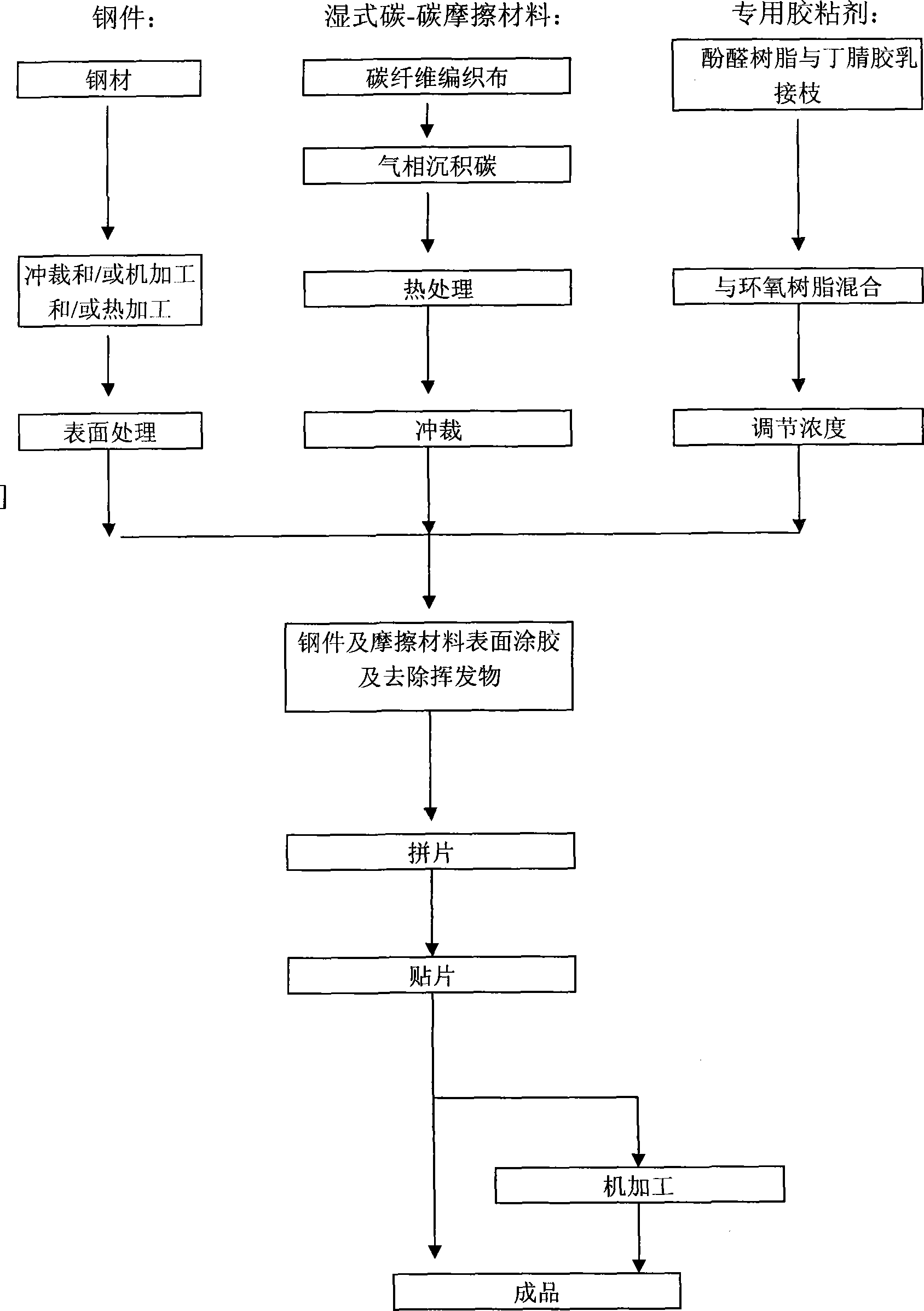

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments: The present invention mainly includes: ① making steel parts, selecting steel materials, punching and / or machining and / or thermal processing, and making special-purpose parts through surface treatment. Steel part; the steel part adopts the structural design and material design of the internal friction elements of the current wet friction clutch, brake and synchronizer;

[0015] ② The production of wet carbon-carbon friction materials uses a single-layer carbon fiber woven cloth as the matrix skeleton. The carbon fiber woven cloth is two-dimensionally woven from 3K or 6K or 12K carbon fibers; As the binding phase, the amount of vapor-deposited carbon accounts for 5%-35% of the total amount, and keeps the material with 25%-55% of connected pores. The wet carbon-carbon friction material is heat-treated at 1700°C-2200°C to densify the vapor-deposite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com