Modification method of single-crystal ternary positive electrode material

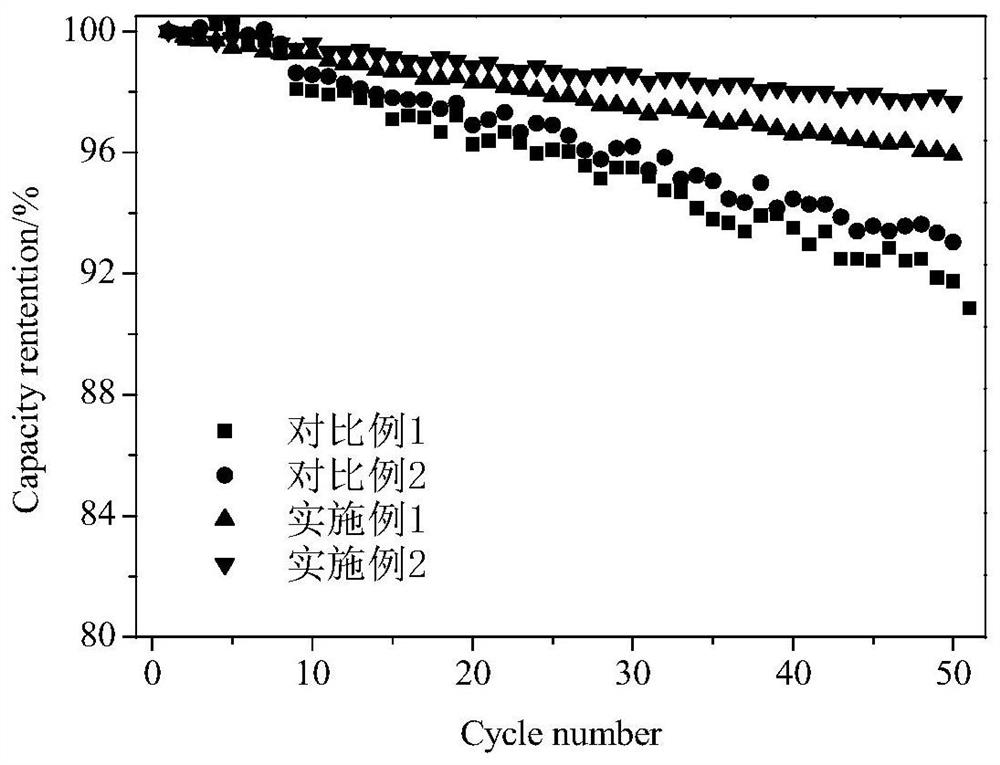

A cathode material and single crystal technology, which is applied in the field of modification of single crystal ternary cathode materials, can solve the problems of poor cycle performance, large polarization of lithium ion batteries, reduced structural stability of ternary cathode materials, etc. Internal resistance, the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

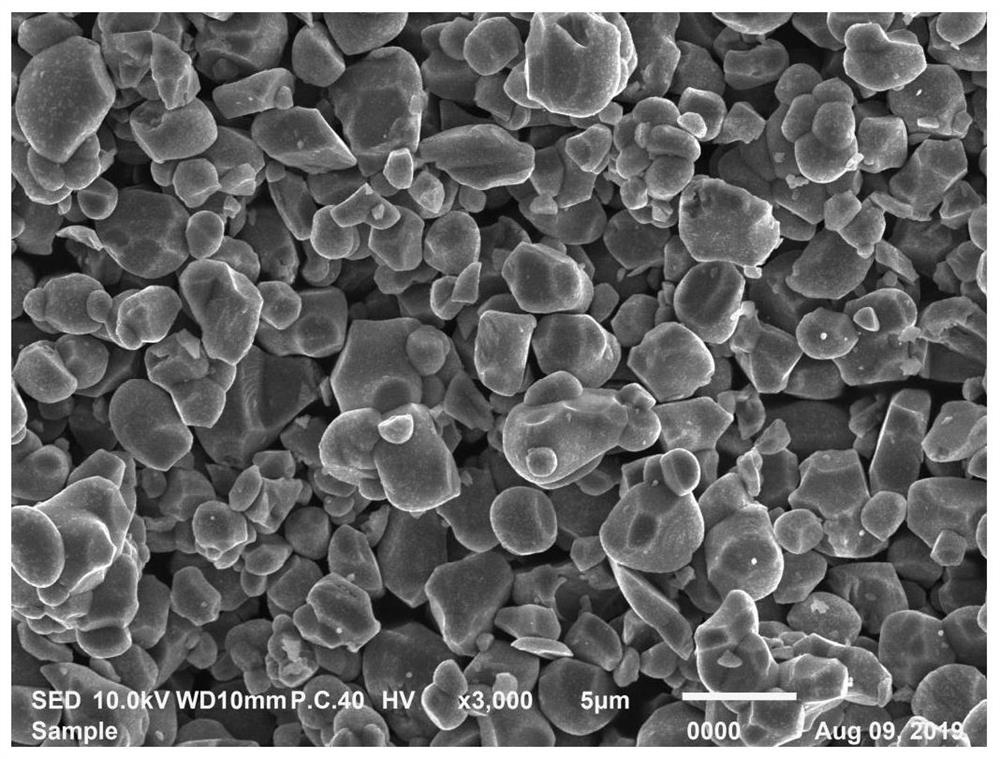

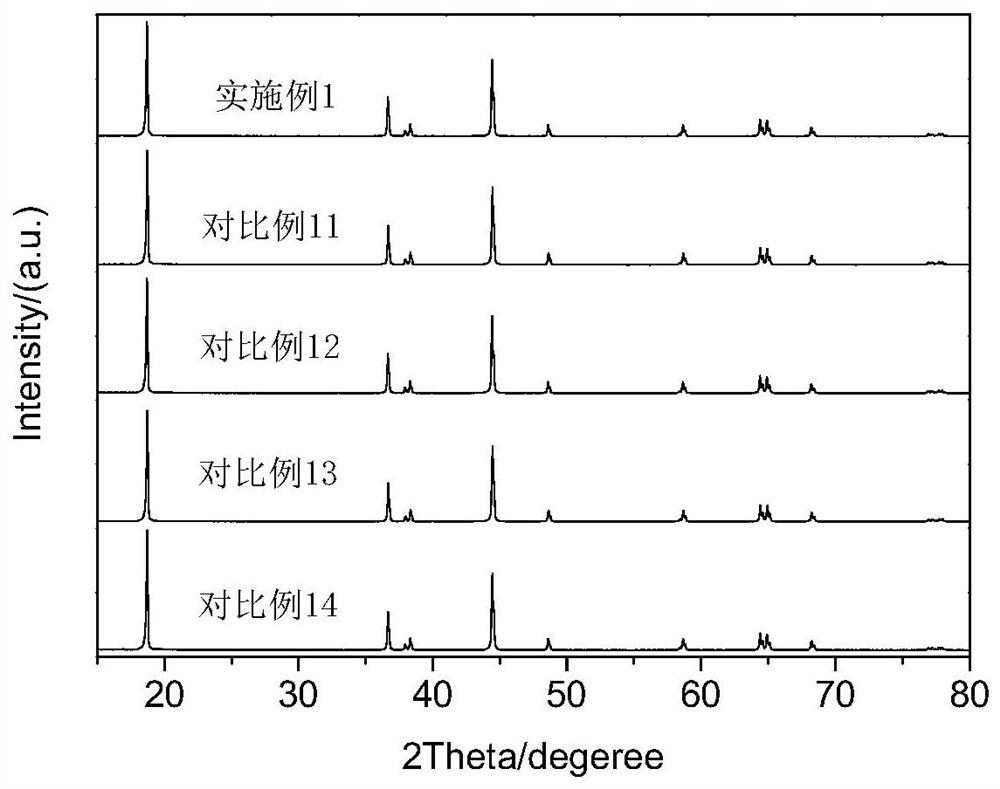

[0032] Preparation of zirconium-doped single crystal material LiNi 0.5 co 0.16 Zr 0.04 mn 0.3 o 2 :

[0033] The ternary positive electrode precursor Ni with a particle size of 3.8 μm 0.5 co 0.2 mn 0.3 (OH) 2 , zirconium sulfate, mixed according to the molar ratio of 1:0.04 according to the mass ratio, added in the container containing water, configured into a mixed solution with a solid content of 5-60wt.%, after spray drying, at a temperature of 400 ° C, In an air atmosphere and a box-type furnace, sintering for 10 h at an air flow rate of 40 L / min to obtain a pre-sintered primary sintered material.

[0034] After the pre-fired primary sintered material and lithium carbonate are mixed uniformly according to the molar ratio of (Ni+Co+Mn) / Li of 1:0.525, at a temperature of 950 ° C, in an air atmosphere and a box furnace, ventilate The amount is 40L / min and sintered for 10h to obtain a doped primary sintered material.

[0035] The doped primary sintered material obtai...

Embodiment 2

[0037] Preparation of single crystal material LiNi doped with zirconium and coated with zirconium metaphosphate 0.5 co 0.16 Zr 0.04 mn 0.3 o 2 :

[0038] According to the molar ratio of 1:0.04, 3.8μm Ni 0.5 co 0.2 mn 0.3 (OH) 2 After physical mixing of zirconium sulfate and zirconium sulfate, it is added to an aqueous solution to form a mixed solution with a solid content of 5%wt. After ball milling for 0.5h, it is spray-dried to obtain a mixture, and the dried mixture is dried in an air atmosphere at a temperature of 400°C. And in the box-type furnace, the ventilation rate is 40L / min and the sintering is 10h, and the primary sintered material after pre-sintering is obtained;

[0039] After the pre-fired primary sintered material and lithium carbonate are mixed uniformly according to the molar ratio of (Ni+Co+Mn) / Li of 1:0.525, at a temperature of 950°C, in an air atmosphere and a box furnace, Sintering for 10h at an air flow rate of 40L / min to obtain a doped primary ...

Embodiment 3

[0046] Preparation of aluminum-doped single crystal material LiNi 0.8 co 0.1 mn 0.06 Zr 0.04 o 2 :

[0047] According to the molar ratio of 1:0.03, the 3.4μm Ni 0.8 co 0.1 mn 0.1 (OH) 2 , aluminum nitrate after physical mixing: adding it to an aqueous solution to form a mixed solution with a solid content of 30%wt., ball milling for 0.5h and then spray-drying to obtain the mixture, and drying the dried mixture at a temperature of 700°C in In air atmosphere and box furnace, sintering at 40L / min for 10h to obtain the primary sintered material after pre-sintering;

[0048] After the pre-fired primary sintered material and lithium hydroxide are uniformly mixed according to the molar ratio of (Ni+Co+Mn) / Li being 1.05, at a temperature of 855°C, in an air atmosphere and a box furnace, ventilate The volume is 40L / min and sintered for 10h to obtain a doped primary sintered material;

[0049] The doped primary sintered material obtained above was sintered for 10 hours in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com