Y/La-doped Co/B co-coated nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A cathode material, nickel-cobalt-manganese technology, which is applied in the field of Y/La doped Co/B co-coated nickel-cobalt-manganese ternary cathode material and preparation field, can solve the cycle performance and rate performance of nickel-manganese-manganese ternary cathode material To achieve the effect of stabilizing the crystal structure, improving the cycle performance and electrochemical performance, improving the cycle life and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the Y / La doped Co / B co-coated nickel-cobalt-manganese ternary positive electrode material provided by the present invention comprises the following steps:

[0023] Step S1, weighing the nickel-cobalt-manganese precursor.

[0024] The types of nickel-cobalt-manganese precursors are not limited here, such as NCM811, NCM523, NCM622 and the like.

[0025] Step S2, according to the metal content of nickel, cobalt and manganese in the nickel-cobalt-manganese precursor, weigh a certain amount of compound containing Y and La and a certain amount of lithium source compound according to the expected ratio.

[0026] Step S3, adding the Y- and La-containing compound together with the nickel-cobalt-manganese precursor and the lithium source compound into a high-speed mixer for thorough mixing, and then calcining to obtain a doped matrix material.

[0027] In this step, the nickel-cobalt-manganese precursor is mixed with Y and La compounds and a lithium sou...

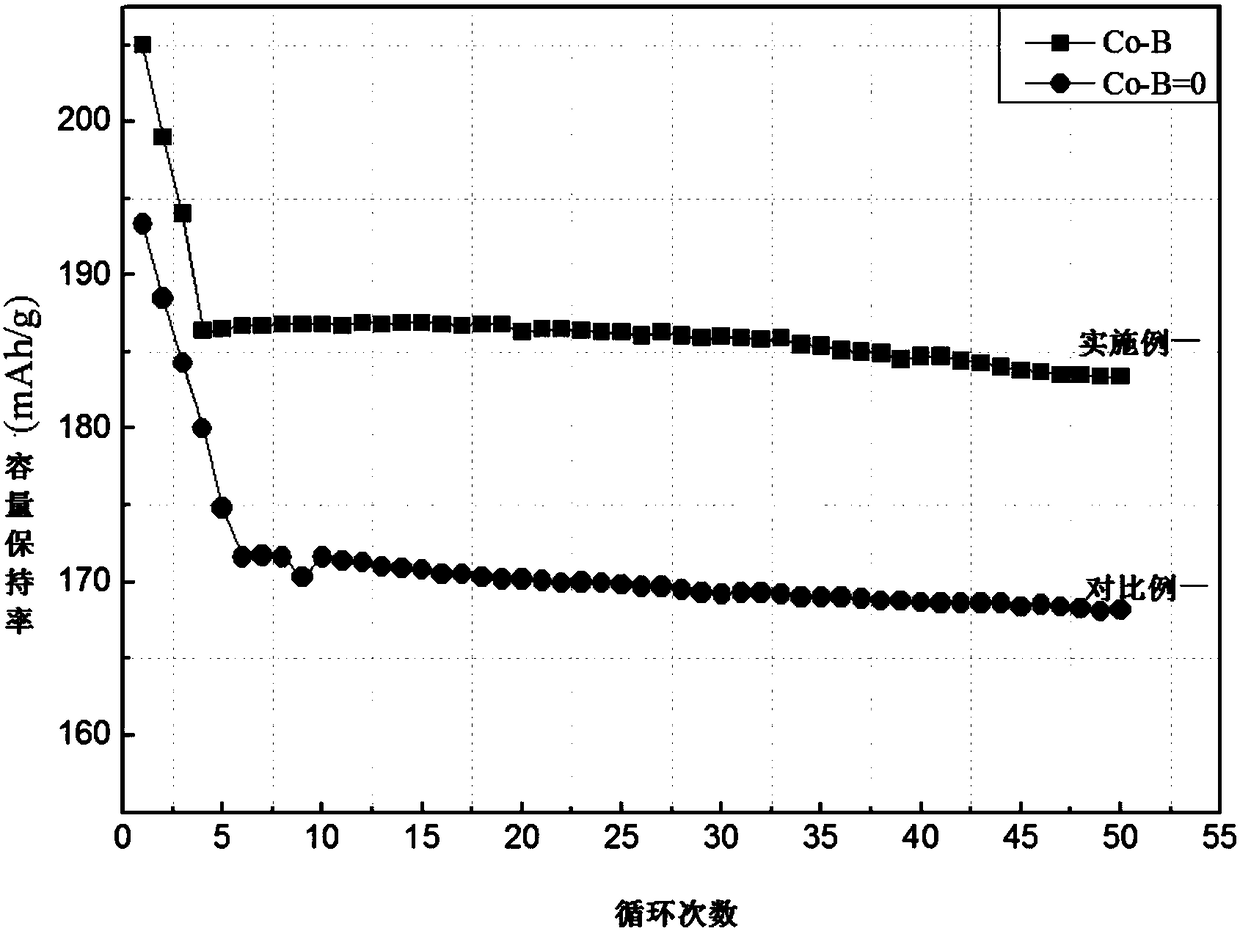

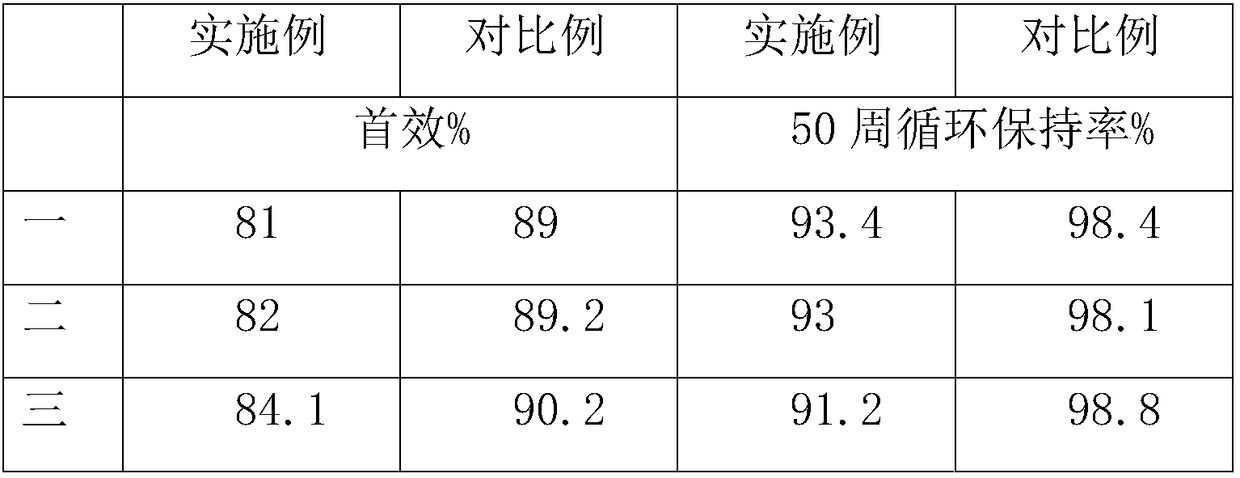

Embodiment 1

[0037] (1.1) Weigh 100g Ni 0.83 co 0.11 mn 0.06 (OH) 2 Precursor, 0.1% doped Y 2 o 3 (0.127g) and La 2 o 3 (0.117g) was added after mixing evenly, lithium hydroxide and precursor powder were added to the high-speed mixer according to Li / (Ni+Co+Mn)=1.01:1.1 and mixed. Sintering at low temperature of 500°C for 240min in oxygen atmosphere, sintering at high temperature of 800°C for 720min, cooling to 600°C for 120min, natural cooling to 100°C to obtain a Y / La doped matrix material for primary sintering.

[0038] (1.2) Add 100g of primary sintered Y / La doped matrix material into 50g of deionized water at 40°C and stir for 10min, drop in 1mol / L cobalt sulfate, stir for 10min, filter and wash, and dry in a rotary evaporator for 60min , after drying in a vacuum oven at 120°C for 480 minutes, the positive electrode material powder coated with cobalt hydroxide was obtained, and then sintered at 700°C for 10 hours in an oxygen atmosphere, and then naturally cooled to 100°C to obt...

Embodiment 2

[0050] (2.1) Weigh 100g Ni 0.80 co 0.10 mn 0.10 (OH) 2 Precursor, 0.1% doped Y 2 o 3 (0.127g) and La 2 o 3 (0.117g) was added after mixing evenly, lithium carbonate and precursor powder were added to the high-mixing equipment according to Li / (Ni+Co+Mn)=1.01:1.1 and mixed. Sintering at low temperature of 500°C for 240min in oxygen atmosphere, sintering at high temperature of 800°C for 720min, cooling to 600°C for 120min, natural cooling to 100°C to obtain a Y / La doped matrix material for primary sintering.

[0051] (2.2) Add 100g of primary sintered Y / La doped matrix material into 50g of deionized water at 40°C and stir for 10min, drop in 1mol / L cobalt oxalate, stir for 10min, filter and wash, and dry in a rotary evaporator for 60min , After drying in a vacuum oven at 120°C for 480min, a positive electrode material powder coated with cobalt hydroxide was obtained, which was sintered for a second time at 700°C for 10 hours in an oxygen atmosphere, and the temperature was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com