Patents

Literature

77results about How to "Act as a skeleton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

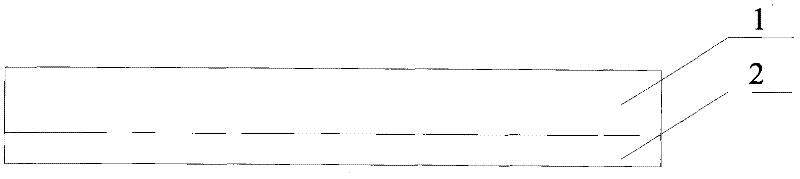

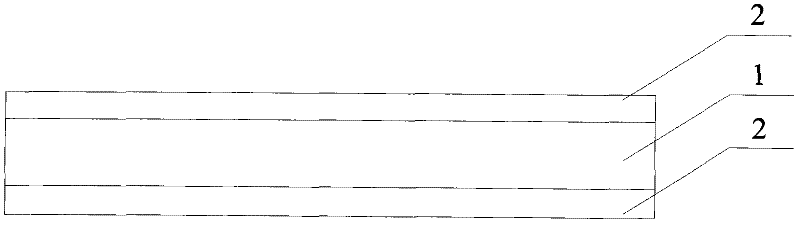

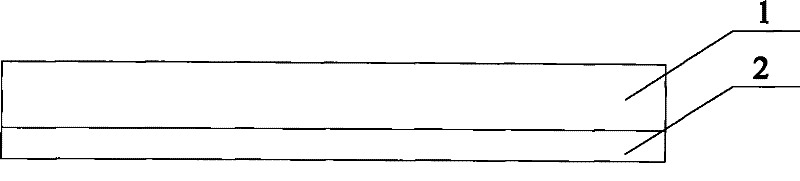

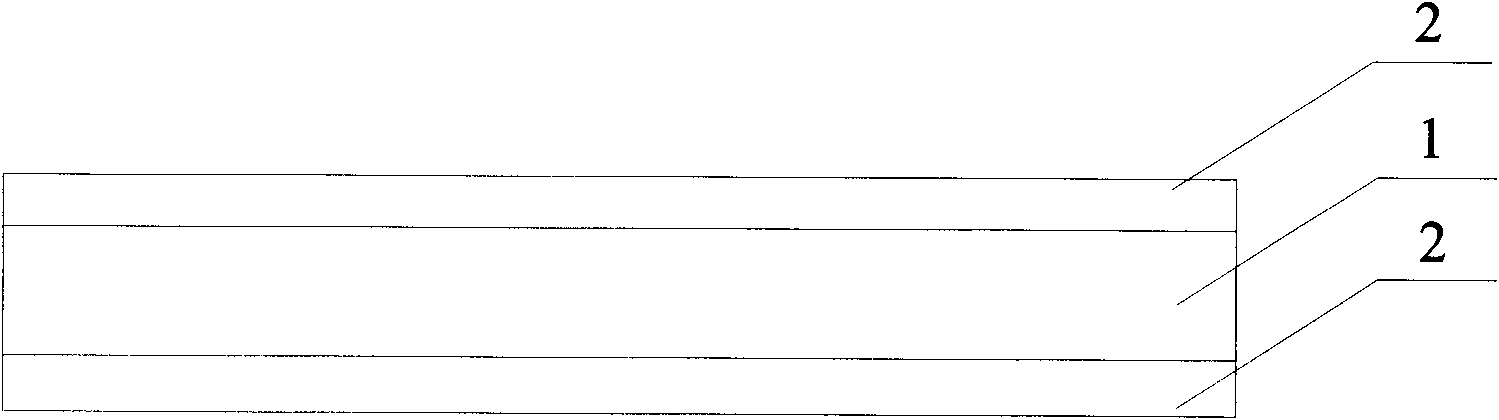

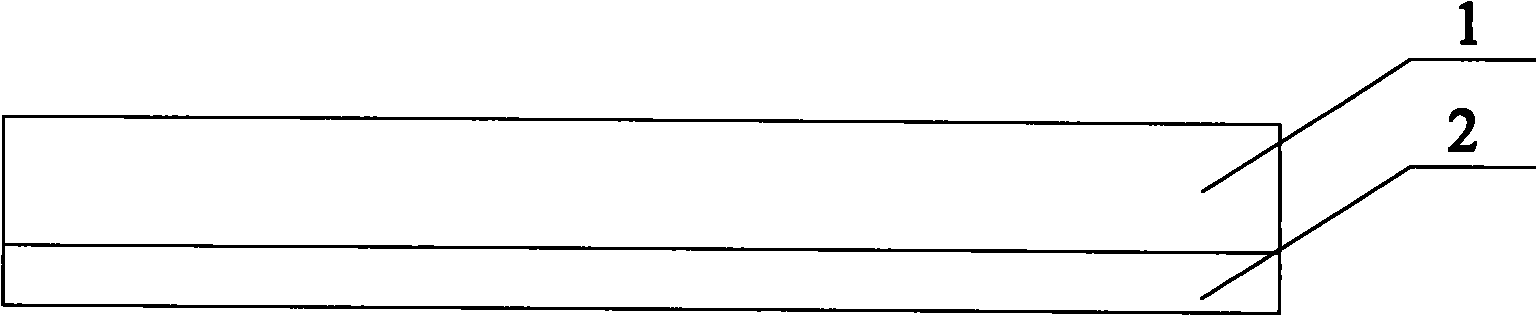

Automobile sound insulation pad in multi-layer structure and manufacturing method thereof

ActiveCN102529840APromote absorptionAct as a skeletonSynthetic resin layered productsVehicle componentsEngineeringHigh frequency

The invention relates to an automobile sound insulation pad in a multi-layer structure and a manufacturing method thereof. The sound insulation pad is of the two-layer or three-layer structure and constituted by a felt hard layer sound insulation material with the density of 200-220kg / m<3> and a polyurethane soft sound insulation material with the density of 60-70kg / m<3> by self-bonding of polyurethane, and the manufacturing method comprises the following steps of getting the low-density sound insulation pad and the high-density sound insulation pad according to a conventional method, heating for softening, die-pressing a layer of the felt hard layer sound insulation material, then placing the hard layer sound insulation material in a foaming die, and performing surface foaming to get the automobile sound insulation pad in the multi-layer structure. Compared with the prior art, the automobile sound insulation pad in the multi-layer structure, disclosed by the invention, can play a role in absorbing and attenuating high-frequency and low-frequency noise and further play the role in reinforcing overall sound insulation and reducing noise, and the a high-density felt hard layer can further play the role of a framework.

Owner:SHANGHAI XINAN CAR DEADENING FELT

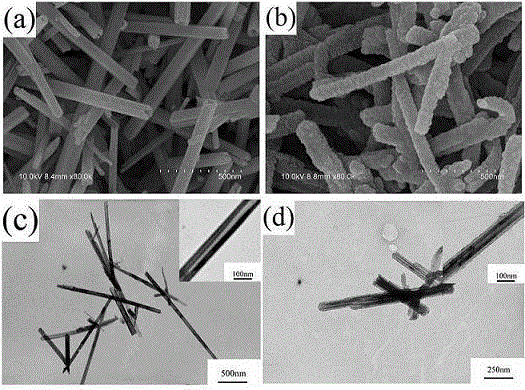

High-specific-capacitance manganese-dioxide conducting polymer composite electrode material with core-shell structure and manufacturing method thereof

InactiveCN103151179AAct as a skeletonHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePolypyrrole

The invention discloses a manganese-dioxide conducting polymer composite electrode material with a core-shell structure. The manganese-dioxide conducting polymer composite electrode material adopts a manganese-dioxide nano material as a core, adopts conducting polymer as a shell and is a composite nano material with the core-shell structure; the manganese-dioxide nano material is nano balls, nano rods, nano wires or nano tubes; and polyaniline, polypyrrole, polythiophene or poly(3,4-ethylenedioxythiophene) is used as the conducting polymer of the shell, the mass fraction of the manganese dioxide in the composite material is 5-95%, and the mass fraction of the conducting high polymer is 95-5%. The manganese-dioxide conducting polymer composite electrode material disclosed by the invention has the advantages that due to the conducting polymer component, the conductivity of the composite material is increased, and the migration rate of electrons in the charging and discharging process are accelerated, so that the specific capacitance of the composite electrode material is increased; the nano manganese dioxide plays a role in a skeleton, so that the damage of the microstructure of the conducting polymer in the charging and discharging process is avoided, and the cyclic life of the electrode material is greatly prolonged; and the conducting polymer and the nano manganese dioxide both play roles in storing charges. The invention discloses a manufacturing method of the electrode material.

Owner:NANJING UNIV

Method for preparing high-gloss PTFE (Polytetrafluoroethylene) dispersion concentrated solution

The invention provides a method for preparing high-gloss PTFE (Polytetrafluoroethylene) dispersion concentrated solution. The method comprises the steps of: adding deionized water, an initiator, a dispersing agent, a stabilizing agent and polymeric monomers into a high pressure reactor to carry out emulsion polymerization reaction to obtain modified PTFE polymer solution and subjecting the modified PTFE polymer solution to aftertreatment concentration to obtain the PTFE dispersion concentrated solution, wherein the polymerization reaction comprises two steps of: adding modified monomers which are 0.02%-0.5wt% of the polymeric monomers into a polymerizer when the feed quantity of the polymeric monomers reaches to 10%-50% of total feed quantity to reduce the crystallinity of a PTFE product and the change internal structures of PTFE primary particles and controlling the adding quantity of the dispersing agent in the polymerization reaction and adopting an adding mode of stepwise and continuously adding in drops to ensure that the particles of the PTFE dispersion solution are shaped like full balls and uniformly distributed and enhance the gloss of the PTFE dispersion solution.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

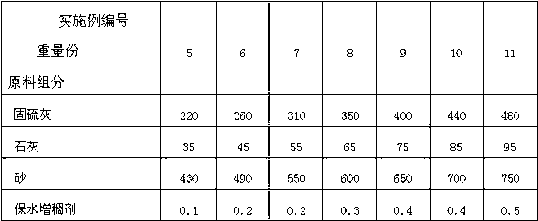

Solid sulfur ash masonry mortar

The invention discloses solid sulfur ash masonry mortar. The solid sulfur ash masonry mortar is characterized by comprising the following components in parts by weight: 200 to 490 parts of solid sulfur ash, 30 to 100 parts of lime, 410 to 770 parts of sand, and 0.1 to 0.5 part of water holding thickener. The solid sulfur ash is used as a main raw material for preparing the masonry mortar, so that solid sulfur ash slag discharged by a circulating fluidized bed can be fully utilized, waste of land resources and pollution to the natural environment when the solid sulfur ash is stacked in open air are reduced, meanwhile, the contractility of the masonry mortar is reduced, the water holding property of the masonry mortar is improved, the cost of the masonry mortar is reduced, and the practicability is strong.

Owner:SOUTHWEAT UNIV OF SCI & TECH

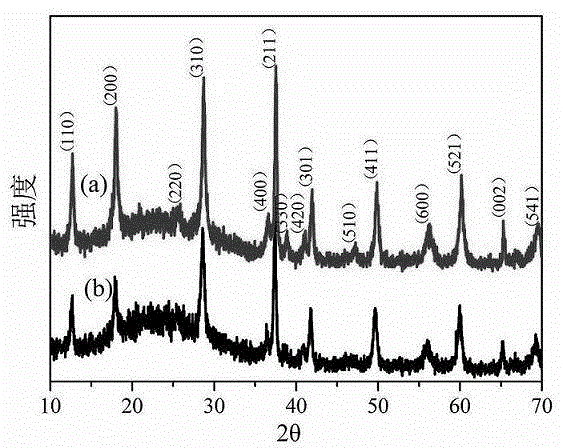

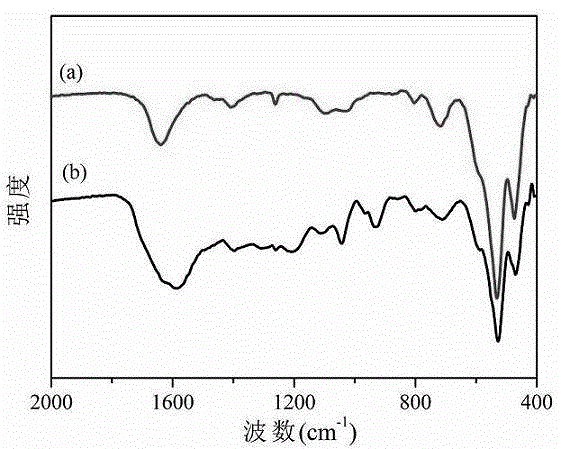

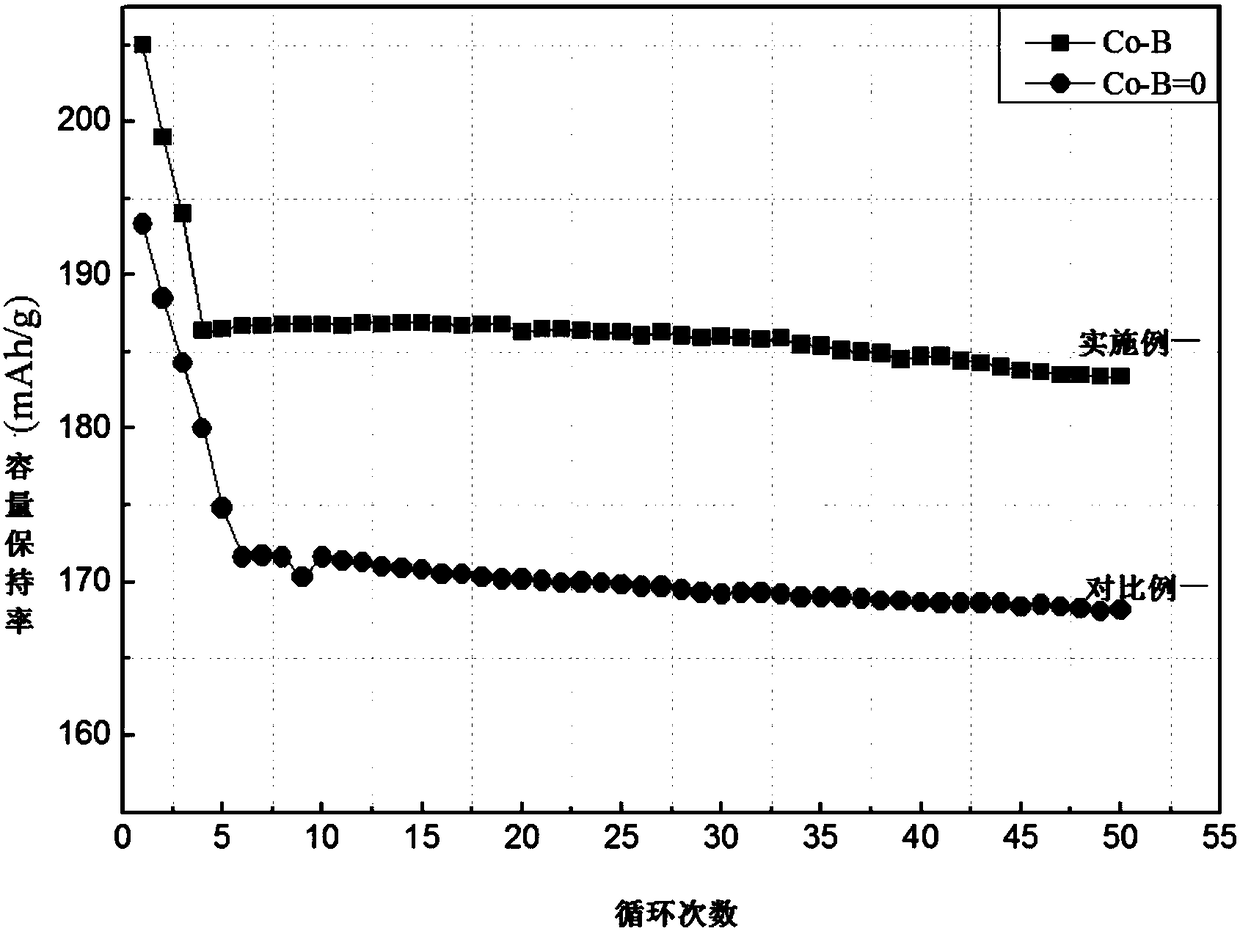

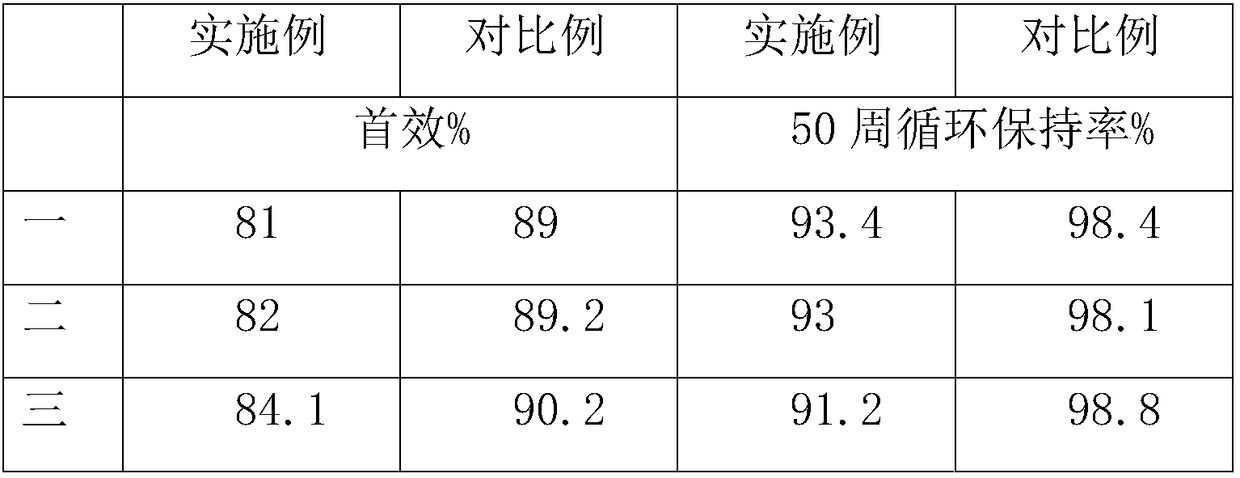

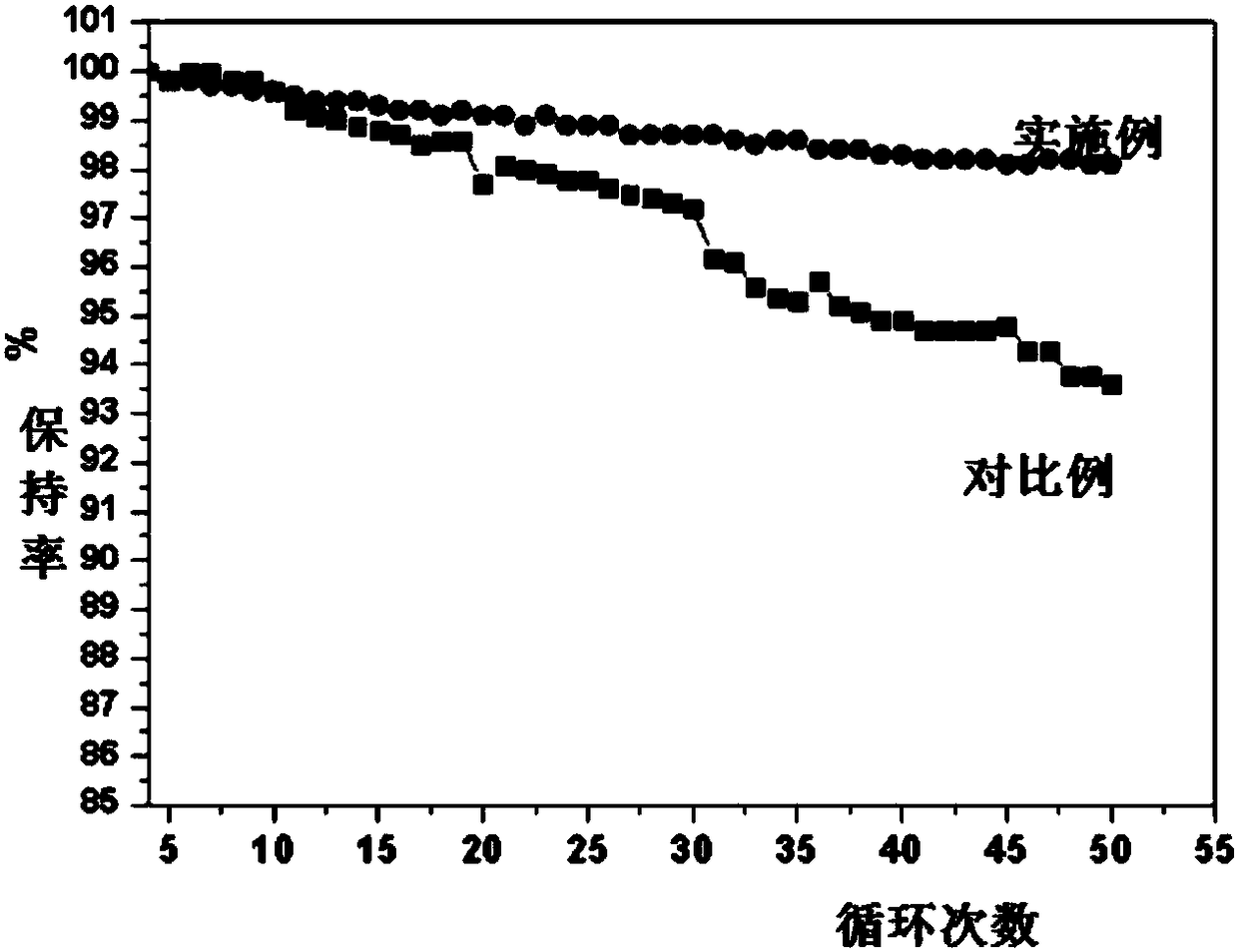

Y/La-doped Co/B co-coated nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

ActiveCN108550802AImprove cycle lifeImprove securityCell electrodesSecondary cellsManganeseSide reaction

The invention belongs to the technical field of lithium batteries, and provides a Y / La-doped Co / B co-coated nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof. According to the present invention, the cycle performance and the safety performance are improved by doping a small amount of Y<3+> ions and La<3+> ions, wherein Y<3+> / La<3+> and Ni<3+> have the same valence state, the doped Y<3+> / La<3+> can enter the metal Ni<3+> position, the Y<3+> / La<3+> does not produce the valence change during the charge and discharge, is electrochemically inert, and doesnot produce the valence state change during the charge and discharge so as not to produce the volume change, such that the Y<3+> / La<3+> can act as the skeleton, stabilize the crystal structure, and improve the cycle life and the safety performance of the material; and under the high voltage, the Co / B co-coated positive electrode material can effectively improve the cycle performance and the electronic conductivity of the battery, reduce the residual alkali, and reduce the flatulence, such that the co-coated nickel-cobalt-manganese ternary positive electrode material can effectively prevent theoccurrence of side reactions so as to improve the cycle performance and the electrochemical performance of the lithium battery.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

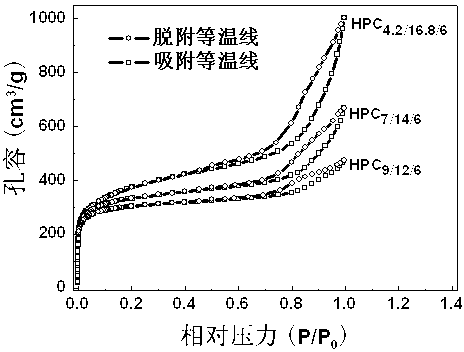

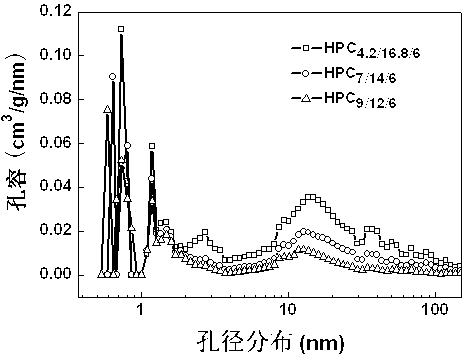

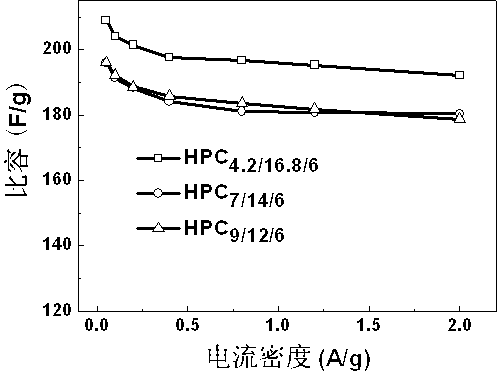

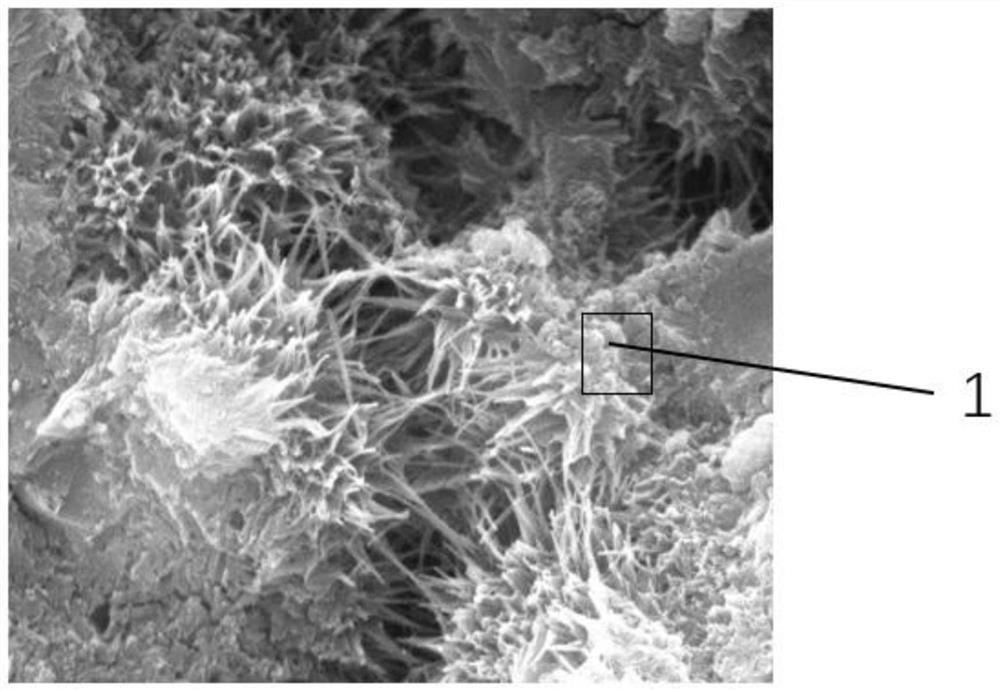

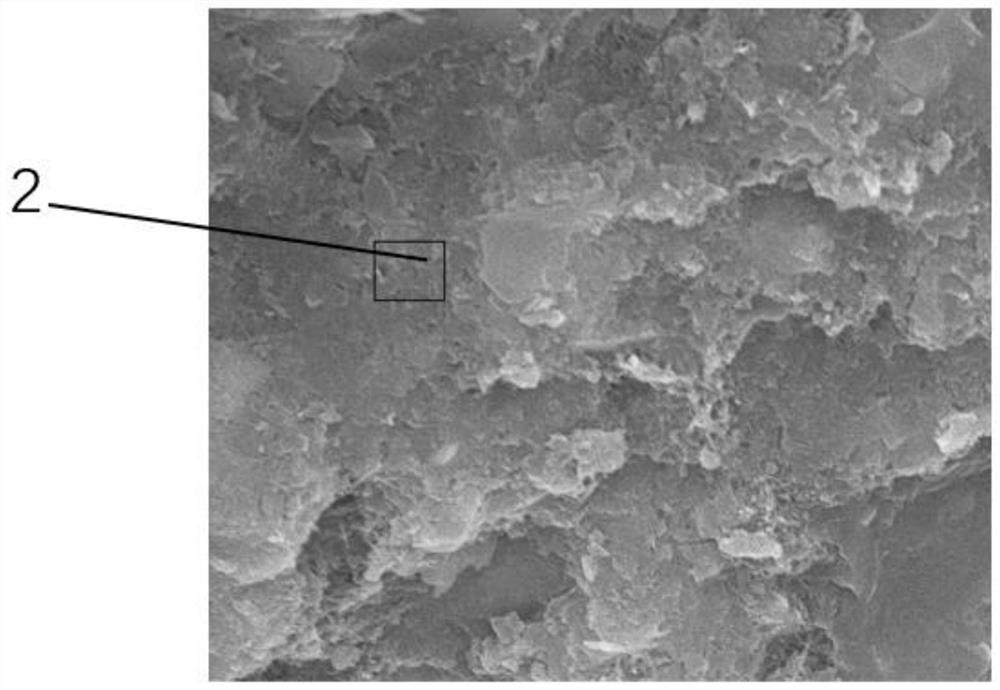

Preparation method of grading porous carbon material

ActiveCN102838105ALow ashOvercome expensiveMaterial nanotechnologyCarbon preparation/purificationActive agentSesquioxide

The invention discloses a preparation method of a grading porous carbon material, and belongs to the technical field of carbon material preparation. The method comprises the following steps: getting cheap coal tar pitch as the carbon source, nanometer iron sesquioxide as a template, and potassium hydroxide as an active agent; grinding the three components; transferring the mixture into a corundum crucible; and heating in an atmosphere furnace, so as to obtain the grading porous carbon material for electrochemical electric container, wherein the grading porous carbon material has the specific surface area between 1157 to 1330m<2> / g, the total pore volume ranges from 0.69 to 1.35cm<3> / g, the average aperture ranges from 2.39 to 4.05nm; the ratio of the pore volume of the non-micropore to the total pore volume ranges from 37.7 to 65.9%; and the yield of the porous carbon ranges from 32.6 to 52.2%. The grading porous carbon material prepared via the method provided by the invention serves as the electrode material of the electrochemical electric container, and is good in stability and excellent in comprehensive performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

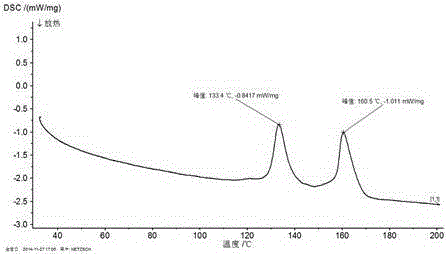

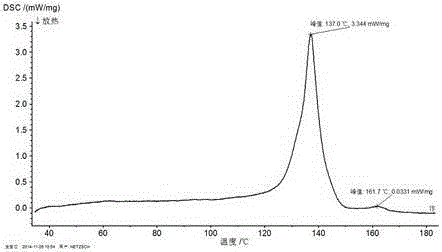

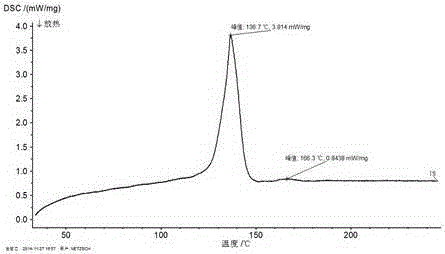

Polyolefin microporous membrane, making method thereof, and lithium ion battery

ActiveCN105355811AIncrease temperatureImprove integrityCell seperators/membranes/diaphragms/spacersSecondary cellsPolymer sciencePolyolefin

The invention relates to a polyolefin microporous membrane, a making method thereof, and a lithium ion battery. The skeleton structure of the microporous membrane is formed by a polypropylene and polyethylene two-phase continuous phase, wherein the mass percentage of polypropylene resin is 50-65%, the mass percentage of polyethylene resin is 35-50%, the intrinsic viscosities of the polypropylene resin and the polyethylene resin are 200-1000ml / g respectively, and a difference between the intrinsic viscosities of the polypropylene resin and the polyethylene resin is 100ml / g. The microporous membrane has the advantages of large safety window, excellent integrity of a high temperature melt, and great improvement of the safety performance of the battery when the microporous membrane is used in the lithium ion battery.

Owner:乐凯胶片股份有限公司

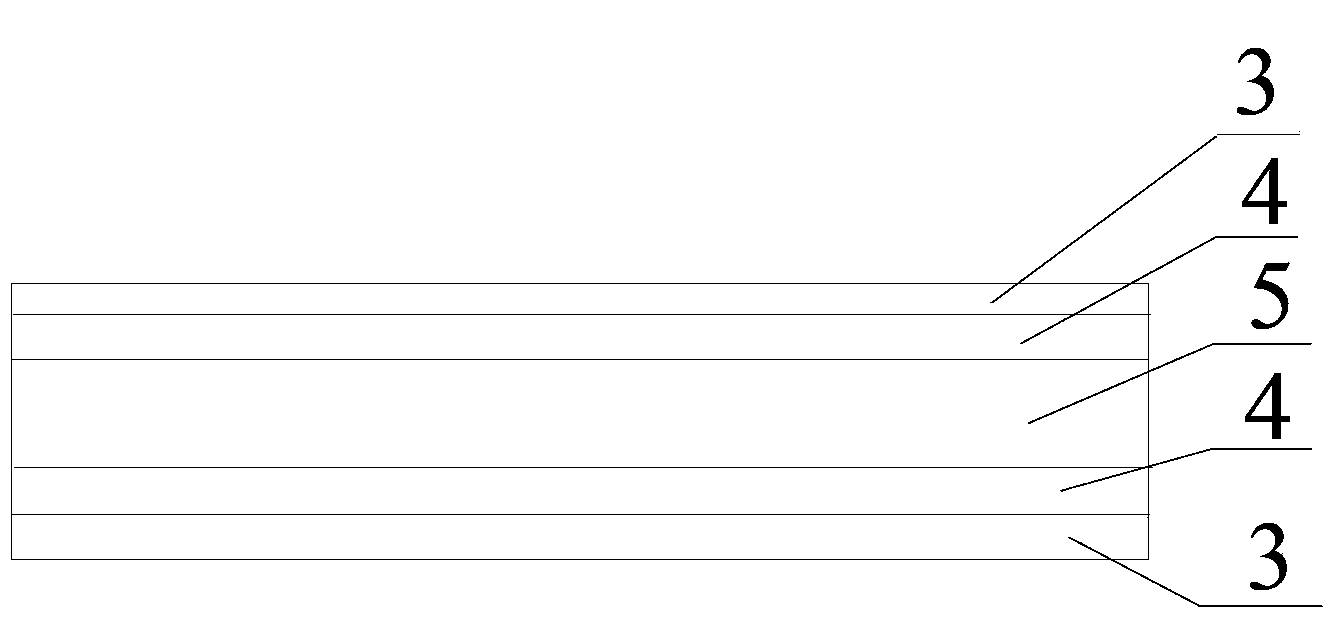

Multi-layer sound insulation pad for automobile and manufacture method thereof

InactiveCN102336167APromote absorptionAct as a skeletonLaminationLamination apparatusUltrasound attenuationEngineering

The invention relates to a multi-layer sound insulation pad for an automobile and a manufacture method thereof. The multi-layer sound insulation pad is composed of 2-3 layers of sound insulation pads with different densities. Various layers of sound insulation materials are bonded through a binder. The manufacture method comprises the following steps of: manufacturing a low-density sound insulation pad and a high-density sound insulation pad by using the conventional method, and heating to soften the sound insulation pads; then, coating the binder at the bonding position, and arranging the sound insulation materials in a forming mould in turn; and finally, closing the mould and pressing the sound insulation materials to obtain the multi-layer sound insulation pad for the automobile. Compared with the prior art, the multi-layer sound insulation pad has the absorption and attenuation functions on high-frequency and low-frequency noises; therefore, the integral noise reduction function is increased; and the high-density layer can also have the framework function.

Owner:SHANGHAI XINAN CAR DEADENING FELT

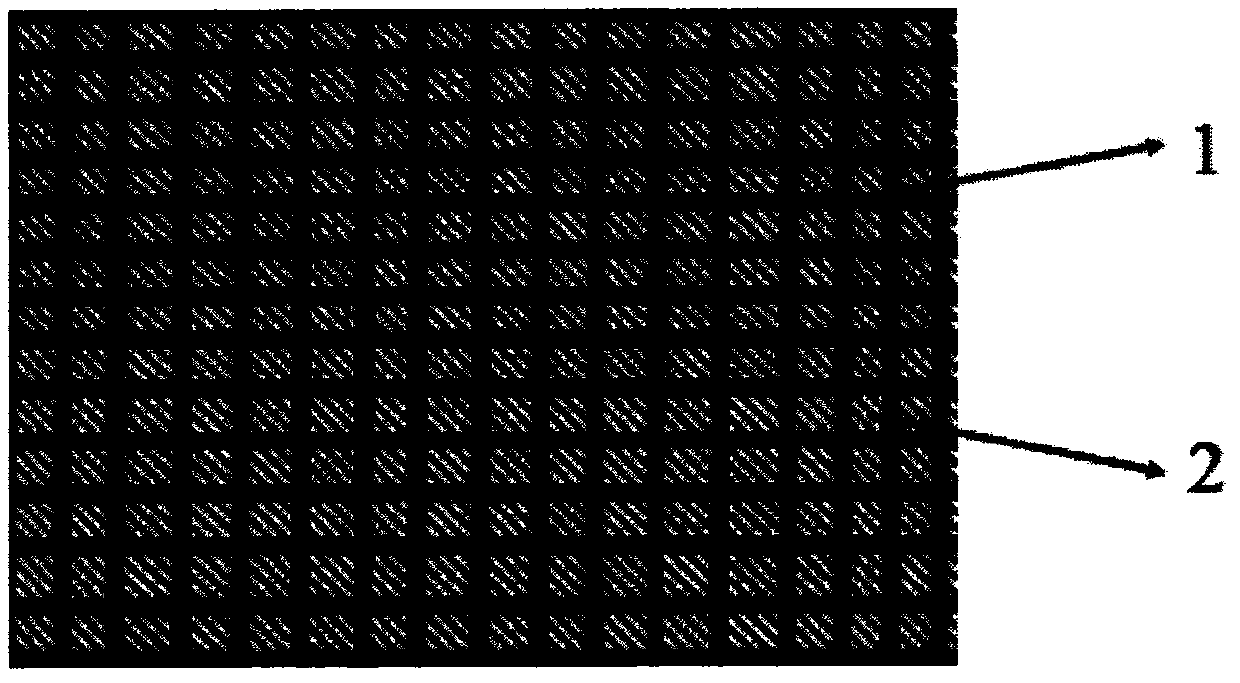

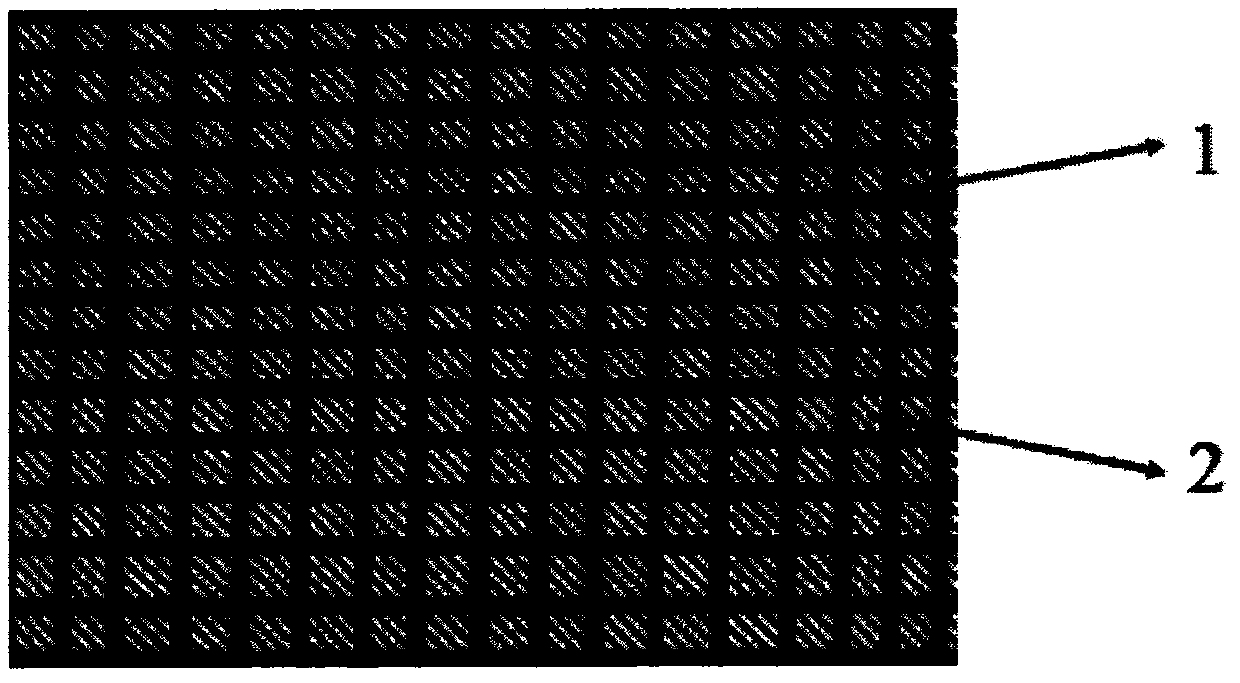

Composite thermal interface material composed of metal mesh and low-melting-point alloy

InactiveCN106701031AHigh thermal conductivityImprove heat transfer performanceHeat-exchange elementsIndiumWorking temperature

The invention provides a composite thermal interface material composed of a metal mesh and a low-melting-point alloy; the low-melting-point alloy exists in mesh openings of the metal mesh in a solid form at room temperature, the low-melting-point alloy is melted at a work temperature and fills a gap of a heat transfer interface, and the metal mesh can prevent overflowing of the low-melting-point alloy, wherein the metal mesh is one of a copper mesh, a stainless steel mesh and a nickel mesh. The low-melting-point alloy is an indium-bismuth-tin-gallium alloy and has the melting point of 40-70 DEG C. The composite thermal interface material has the advantages of simple structure, high thermal conductivity, convenience in use, safety and reliability, and can avoid contamination or short circuit fault of equipment due to overflowing of liquid alloys.

Owner:CHINA EPRI ELECTRIC POWER ENG CO LTD +1

Anti-corrosion polyurethane-epoxy resin composite emulsion coating

InactiveCN105153907AImprove adhesionGood compatibilityAntifouling/underwater paintsPaints with biocidesCarbon nanotubeDefoamer

The invention discloses anti-corrosion polyurethane-epoxy resin composite emulsion coating, which is prepared from the following raw materials: polyurethane-epoxy resin composite emulsion, fluorocarbon resin emulsion, polytetrafluoroethylene emulsion, polyphenylene sulfide resin, tetrafluoroethylene-hexafluoropropylene copolymer, nano-silicon sol, nano-zinc oxide, zinc phosphate, iron-titanium compound powder, nanometer titania, hexahydro-1,3,5-tri(ethoxy)-s-triazine, water-borne polyaniline, carbon nano tube, hollow microspheres, nanometer aluminum nitride, organic-modified montmorillonite, iron oxide yellow, gamma-isocyanate-triethoxypropylsilane, hydrogenated castor oil, defoamer, cosolvent, alcohol ester-12 and deionized water. The anti-corrosion polyurethane-epoxy resin composite emulsion coating disclosed by the invention has good water tolerance and weather fastness and excellent corrosion resistance and impact resistance and is long in service life.

Owner:TIANCHANG YINHU PAINT

Composite thermal interface material of orientated pored graphene foam and low-melting-point alloy

InactiveCN106675529AHigh thermal conductivityImprove heat transfer performanceHeat-exchange elementsIndiumWorking temperature

The invention provides a composite thermal interface material of orientated pored graphene foams and a low-melting-point alloy. At normal temperature, the low-melting-point alloy exists in pores of the graphene foams in a solid manner; at working temperature, the low-melting-point alloy is molten and filled into pores of heat conduction interfaces, and the low-melting-point alloy can be prevented from overflowing by the graphene foams; the low-melting-point alloy is an indium-bismuth-tin-gallium alloy; the melting point of the low-melting-point alloy is within 40-70 DEG C; the graphene foams are of a pored structure parallel to a heat conduction direction. After the low-melting-point alloy is filled, the heat conductivity in the heat conduction direction can be greatly improved.

Owner:CHINA EPRI ELECTRIC POWER ENG CO LTD +1

Composite type vehicle sound insulation pad

InactiveCN103182813APromote absorptionAct as a skeletonSynthetic resin layered productsHeating/cooling textile fabricsHigh densityEngineering

The invention relates to a composite type vehicle sound insulation pad, which is compounded by multiple sound insulating material layers of different densities. The sound insulating material layers are bonded by a binder and are subjected to hot pressing molding. Compared with the prior art, the sound insulation pad provided in the invention can absorb and attenuate high-frequency and low-frequency noise so as to achieve the effect of strengthening overall noise reduction, and the high density layer can also play a skeleton role.

Owner:SHANGHAI XINAN CAR DEADENING FELT

Solidification and desiccation process of sludge

InactiveCN106007324AReduce moisture contentSmall particle sizeSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSludgeDesiccation

The invention discloses a sludge solidification and drying process. The specific steps are as follows: 1) put the raw sludge into a stirring dryer, and add 5% solidifying agent of the input amount of the raw sludge; 2) set the temperature of the stirring dryer 80-160°C, stirring for 2-3 hours to obtain granular sludge with a water content reduced to no more than 40%. The solidification and drying process of sludge disclosed in the technical solution of the present invention adopts chemical modification and solidification, plus low-temperature drying to treat sludge, which can effectively improve the efficiency of sludge drying. It has changed and has the characteristics of ordinary soil, and it will not reverse into sludge when it meets water. Due to the use of low-temperature drying, the stench produced by high temperature and the harmful gas such as dioxin produced by high-temperature incineration are avoided.

Owner:无锡市华东电力设备有限公司

Plant empty capsule and manufacturing method thereof

InactiveCN104274424AReduce moisture contentWide applicabilityPharmaceutical non-active ingredientsCapsule deliveryCelluloseCarrageenan

The invention provides a plant empty capsule with a good moulding effect, high surface smoothness and good elasticity and a manufacturing method thereof. The plant empty capsule comprises 88-90wt% of complex gum, 1-3wt% of potassium chloride, 0.3-0.5wt% of humectant, 0-0.2wt% of polysaccharide, 3-5wt% of medical glycerinum, 1-3wt% of titanium dioxide and 0.2-0.3wt% of food colourant, wherein the complex gum comprises carrageenan, plant cellulose and sodium carboxymethylcellulose. The plant empty capsule is low in water content, is especially applicable to being filled with medicines which have strong hygroscopicity and are sensitive to moisture, has the advantages of wide applicability, no crosslinking reaction and high stability and is preservative-free, and microorganisms can hardly grow on the empty capsule; and meanwhile, the plant empty capsule is hardly crisp or broken at a low temperature and is still stable in capsule shell character at a high temperature.

Owner:韩字光

Preparation method for aerated concrete block

InactiveCN108821660AHinder the formation of subsidence cracksImprove crack resistanceCeramicwareAmmonium polyphosphateSmoke

The invention provides a preparation method for an aerated concrete block, belonging to the field of building materials. According to the invention, high-temperature-resistant polypropylene fibers arereasonably used, so the segregation of aggregate is effectively hindered, the formation of settlement cracks is prevented, and the crack resistance of the aerated concrete block is greatly improved;the dehydration catalyst ammonium polyphosphate in the invention is decomposed with heat to produce an acidic substance, a hydroxyl group on the charring agent melamine is dehydrated and carbonized toform a non-flammable three-dimensional carbonaceous layer, and a porous sponge-like foam carbonaceous layer is finally formed under the framework action of the carbonaceous layer, so the prepared aerated concrete block has light weight and good thermal insulation performance; and since graphene oxide has barrier action on gas molecules, smog and solid particles, when the graphene oxide is uniformly dispersed in a permeable polymer matrix, the smoke production capacity of the aerated concrete block is significantly reduced.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Lithium nickel-cobalt-iron positive electrode material and preparation method thereof

ActiveCN108400321AImproved magnification performanceImprove cycle lifeCell electrodesSecondary cellsIridiumIndium

The invention is applied to the field of lithium batteries, and provides a lithium nickel-cobalt-iron positive electrode material and a preparation method. The method comprises the steps that an indium-iridium-doped nickel-cobalt precursor is prepared and then subjected to mixed sintering with ferroferric oxide micropowder to obtain an indium-iridium-doped nickel-cobalt-iron positive electrode material, then the indium-iridium-doped nickel-cobalt-iron positive electrode material is mixed with a coating agent for secondary sintering, and finally the coating agent-coated lithium nickel-cobalt-iron positive electrode material is obtained. According to the positive electrode material, the crystal structure is stable, the coating layer is not prone to separate, and In<3+> and Ir<3+> are at constant valence in the charging and discharging process, are electrochemically inactive, do not generate valence state changes during charging and discharging or generate size changes, can achieve a skeleton effect and are beneficial to prolonging of the cycle life of the material and improvement of the security performance of the material.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Method of using plain soil to produce hydraulic engineering seepage-proofing brick in situ

InactiveCN102633485AImprove adsorption capacityHigh compressive strengthSolid waste managementBrickHydraulic engineering

The invention relates to the field of building materials and the field of water conservancy construction, in particular to various clay, weathered granite soil and hoggin soil. Soil at construction sites of artificial lakes, artificial canals and irrigation channels is used as main materials, special macromolecular coagulant, limestone or gravel sandy soil are mixed with Portland cement, and compression molding equipment is used for once forming of seepage-proofing bricks. The main materials include, by weight, 0.02 part of coagulant, 0.2 part of glass fiber chopped strands (biological straws), 70-80 parts of soil, 5-6 parts of cement and 10-15 parts of gravels (weathered granite soil). In terms of performance, the seepage-proofing bricks made by the method have sufficient compressive strength and shear resistance and can meet the normal artificial water conservancy seepage proofing requirements; in terms of process, operation is simple and easy and soil is taken in situ; and in terms of cost, the cost is at least 50% lower than that of cement mortar seepage proofing, soil needed to be removed at the construction sites is treated, construction cost is reduced, and construction cycle is shortened.

Owner:蒋黔湘 +3

Radiation-resistant putty powder

InactiveCN104592800AGood anti-radiation functionAct as a skeletonFilling pastesCelluloseElectromagnetic radiation

The invention discloses radiation-resistant putty powder which comprises the following raw materials in parts by weight: 30-50 parts of heavy calcium carbonate powder, 30-50 parts of ash calcium powder, 5-15 parts of hydroxypropyl methyl cellulose, 5-10 parts of lignocellulose, 0.5-2 parts of pigments, 1-5 parts of diatomite, 2-7 parts of light calcined magnesia, 5-10 parts of shielding materials and 5-10 parts of probiotics powder. The radiation-resistant putty powder is obtained by preparing the raw materials according to a formula and placed into a stirrer to be stirred and sealing in bags after being uniformly stirred, and is stirred with water when used. The putty powder disclosed by the invention ensures that the wall surface of a house has radiation-resistant capacity, can be used for effectively shielding the electromagnetic radiation source and is environmentally friendly, economic and affordable. According to the putty powder, the hydroxypropyl methyl cellulose and the lignocellulose play skeleton roles, so that the use intensity of putty is enhanced; and the diatomite and the light calcined magnesia have excellent moistureproof property and chemical resistant property, so that the wall surface has no scaling, no bulging, no desquamation and excellent abrasion resistance and washing resistance after the putty is brushed to an inner wall.

Owner:昆山文创建筑装饰工程有限公司

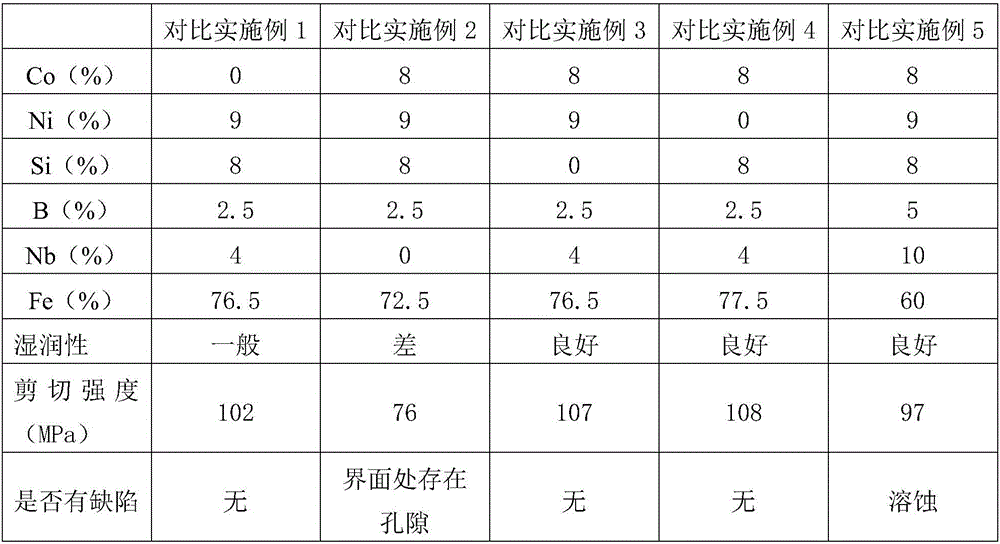

High temperature Fe-based solder for brazing 50Mo-50Re alloy and preparation method thereof, and brazing process

ActiveCN106271209AHigh melting pointHigh melting temperatureWelding/cutting media/materialsSoldering mediaMo elementSolid solution

The invention discloses a high temperature Fe-based solder for brazing 50Mo-50Re alloy and preparation method thereof, and brazing process. The solder includes the components with following weight ratios: Co 4wt%-9wt%, Ni 3wt%-12wt%, Si 3wt%-8wt%, B 0wt%-3wt%, Nb 3wt%-5wt%, and the balance Fe. The preparation method for the high temperature Fe-based solder comprises the following steps: mixing Fe particles, Si particles, B particles, Co particles, Ni particles and Nb particles evenly in proportion, making the solder into foil strip shape with a thickness ranging from 20-50Mum by using vacuum induction melting furnace and high vacuum spinning machine. The temperature for brazing the solder ranges from 1060-1160 DEG C, and the melting temperature of the solder keeps extremely high to ensure the high temperature performance of a weld. The solder is molten uniformly. The use of solder foil is conducive to promoting the diffusion of alloy elements in soldered connection process, and the solder foil is conducive to promoting element diffusion in soldered connection process. Solid solution can be generated by Fe element and Mo element; Co element and Nb element can promote the diffusion of Mo element and Re element in a brazing seam, so as to form a wide diffusion layer. The performance of the brazing seam is improved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Preparation method of inorganic foam building thermal insulation material

InactiveCN103524101AImprove air tightnessUniform pore size distributionCeramicwareThermal insulationPulverized fuel ash

The invention provides a preparation method of an inorganic foam building thermal insulation material. The preparation method comprises the following steps: dispersing polypropylene fibers, pulverized fuel ash, sulphate aluminosilicate cement, calcium stearate, perlite, manganese dioxide and triethanolamine to water, and stirring, thus obtaining unfoamed slurry; and adding hydrogen peroxide with 30% of mass concentration to the unfoamed slurry, then molding the obtained pre-foamed slurry by casting, maintaining, demolding, and cutting, thus obtaining the inorganic foam building thermal insulation material. The preparation method has the advantages that the foaming process is controlled by controlling the mixing amount of the manganese dioxide catalyst so as to ensure the strength of the inorganic foam building thermal insulation material, simultaneously reduces the heat conductivity of the inorganic foam building thermal insulation material and enhances the heat preservation effect of the inorganic foam building thermal insulation material, the perlite is added so as to serve as an anti-collapse agent so as to reduce the rejection rate, and meanwhile, the triethanolamine is added so as to improve the property of the inorganic foam thermal insulation material. Compared with materials of the same kind, the inorganic foam building thermal insulation material has the characteristics of high strength, low heat conductivity, small volume weight, burning resistance, flame resistance and the like.

Owner:SHANGLUO UNIV

Classification method for waste concrete block treatment

The invention discloses a classification method for waste concrete block treatment. The invention belongs to the technical field of waste concrete block treatment. The method comprises that waste concrete blocks are pretreated, after air drying, a microwave emission device is used for heating the waste concrete blocks, after heating, the waste concrete blocks are crushed for multiple times by adopting a crusher, the recycled aggregate is subjected to classification treatment, the recycled coarse aggregate is used in new concrete to play a role of a skeleton, and the recycled fine aggregate isused as mortar sand or a filling material of a gel feeding material to treat waste concrete blocks and then classify the waste concrete blocks for use, so that exploited stones can be effectively reduced, the environment is protected and the stones are repeatedly utilized. The method is a eco-friendly, economic and sustainable generation mode, the recycled aggregate is classified in a particle size mode, the application range of the recycled aggregate can be considered according to the classification standard, the recycled aggregate can be used in a more targeted mode, the difference of different regions is met, and therefore workers can use the recycled aggregate more conveniently.

Owner:汉江城建集团有限公司

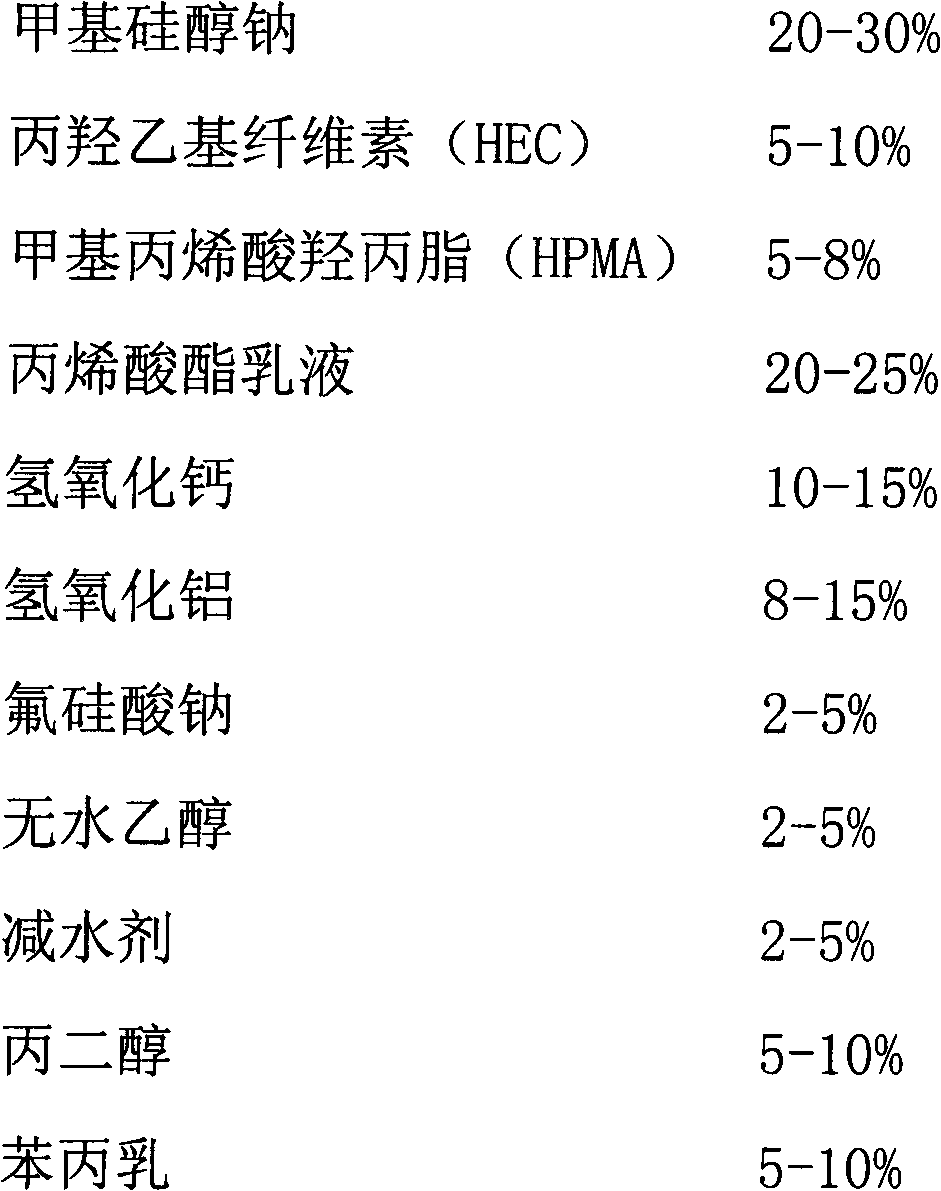

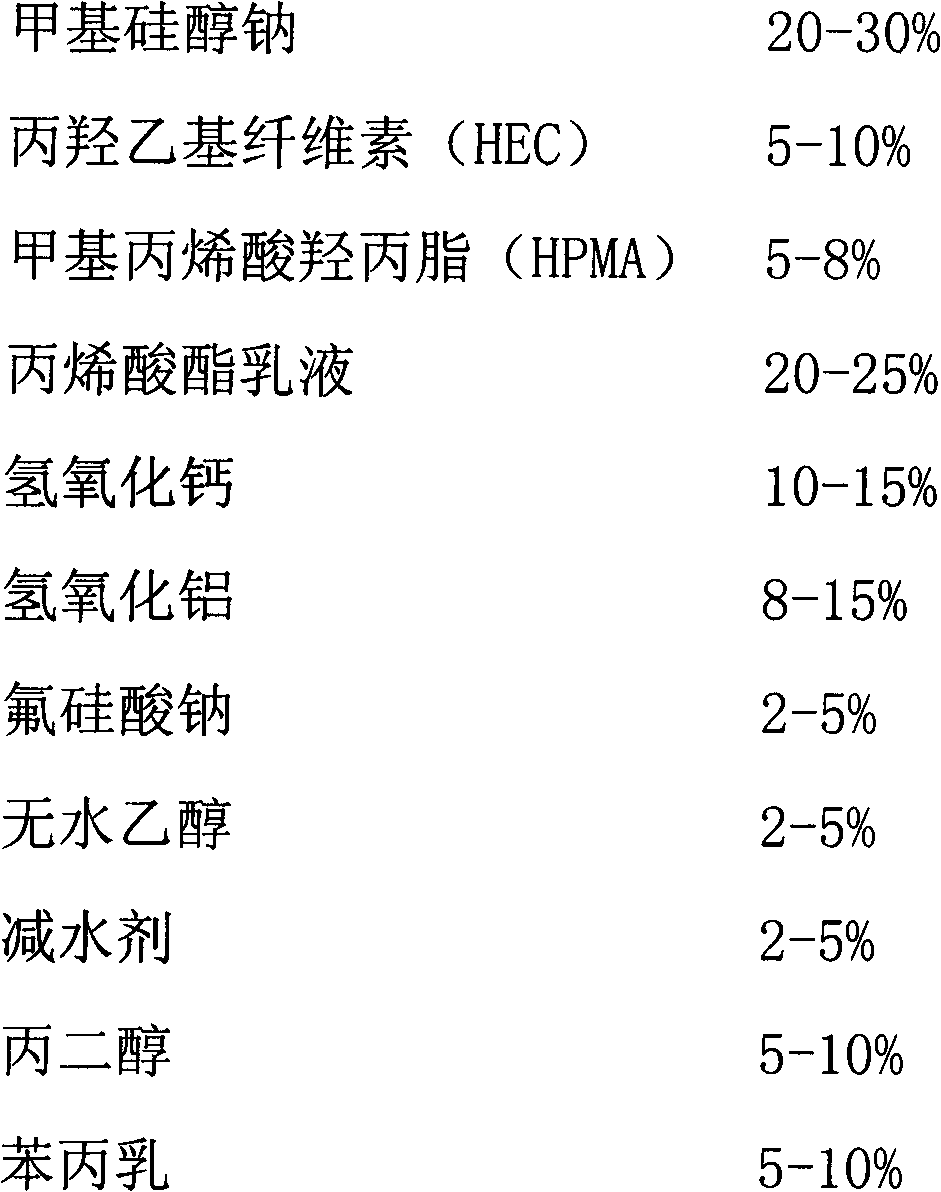

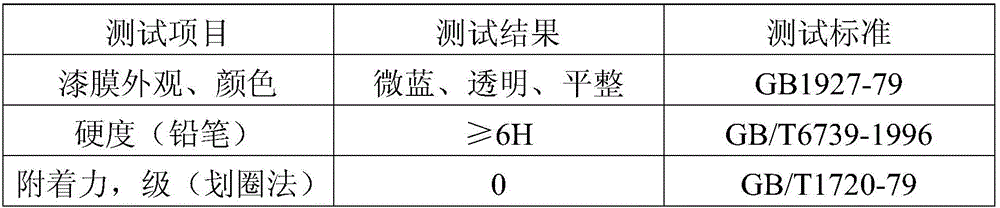

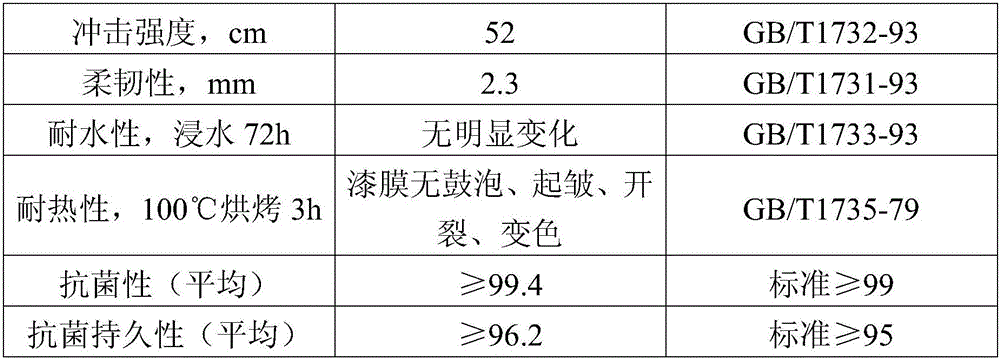

Antibacterial nano-coating, preparation method thereof, and antibacterial nano-coating cloth

ActiveCN106085044AFew types of componentsSimple processLiquid surface applicatorsAntifouling/underwater paintsAcrylic resinGraphene

The invention discloses an antibacterial nano-coating, a preparation method thereof, and an antibacterial nano-coating cloth. The coating includes, by weight, 20-40% of aqueous acrylic resin, 10-20% of aqueous amino resin, 15-30% of ATO nano-dispersion, 5-10% of LaB6 nano-dispersion, 5-15% of WO3 nano-dispersion, 0.5-1% of a leveling agent, 0.5-1% of an antifoaming agent, 10-20% of deionized water, and 0.5-1% of nano-rice husk-nano-silver dispersion, wherein a mass ratio of nano-rice husks to nano-silver is (20-50):1. The rice husks adopted as a component raw material has wide sources, is cheaper than graphene, greatly reduces the production cost, and has an antibacterial effect, and small amounts of granular carbon and silica play a role in skeleton to improve the impact strength of the coating.

Owner:科兰建筑材料(马鞍山)有限公司

Putty for inner wall

InactiveCN104559403AAct as a skeletonIncrease usage intensityFilling pastesCelluloseSodium Bentonite

The invention discloses putty for an inner wall. The putty is prepared from the following raw materials in parts by weight: 70-100 parts of calcium powder, 2-10 parts of hydroxypropyl methyl cellulose, 1-5 parts of lignocellulose, 0.5-2 parts of pigment, 1-5 parts of diatom ooze and 5-10 parts of sodium bentonite. The raw materials are prepared according to the weight portion, are stirred in a stirrer, and are packaged and sealed after being uniformly stirred. The anti-freeze putty powder is mixed with water when being used. According to the anti-freeze putty powder, hydroxypropyl methyl cellulose and lignocellulose have the effect of a frame, and the using strength of putty can be improved; and diatom ooze and sodium bentonite have excellent damp prevention and chemical resistance. After the putty is applied to an inner wall, the wall surface does not peel, blister or separate, and has excellent abrasion resistance and washing durability.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

Preparation method of mask interlayer interlayer filter material

ActiveCN109011918AHigh porosityImprove filtration performanceDispersed particle filtrationFiltration separationElectrospinningFilter material

The invention provides a preparation method of a mask interlayer interlayer filter material, comprising the following steps: S1. preparing a fibrillated plant fiber solution; S2. preparing a hydrogelfilm; S3. preparing a fibroin electrolytic spinning film by electrospinning of a spinning solution, and coating both sides of the fibroin electrolytic film with a composite solution prepared in Step S2, and then compounding the hydrogel film on both sides to obtain a composite film; S4. putting the composite film in a freeze-dryer and freeze-drying to obtain a freeze-dried film; and S5. fixing thefreeze-dried film on a receiving plate of an electrospinning machine, and carrying out electrospinning on both sides of the freeze-dried film through the same spinning solution in the Step S3 so as to obtain the mask interlayer interlayer filter material. The mask interlayer interlayer filter material has good adsorption and filtration effects.

Owner:TAICANG AN YOU NO WOVEN SCI TECH CO LTD

Energy-saving kiln and preparation method thereof

The invention discloses an energy-saving kiln and preparation method thereof. The weight and percentage of components used for energy-saving kiln are as follows: SiSiC:85%-98%; Al2TiO5:0.15%-10%; B4C:0.1%-3%; Si2ON2 or Si3N4: 0.1%-3%; adhesive: 0.13%-3.5%; the balance is water, and the total amount is 100%; wherein the SiSiC is a mixture of particles with a particle size of 5-95 and a fine powderwith a particle size of from 130-380; the Si2ON2 or Si3N4 and Al2TiO5 are micro-powders with a particle size of less than 9 micrometer. The energy-saving kiln and preparation method can solve the problems of complicated production technology, high equipment requirements, large investment, high production cost, and the like in the market promotion process of silicon nitride and recrystallized silicon carbide products in the prior art, and the energy-saving kiln furniture prepared by the invention has high temperature resistance. The energy-saving kiln and preparation method has the advantagesof energy saving (natural gas saving), small volume, small deformation, light weight, high strength, strong oxidation resistance, regular appearance and remarkable service life.

Owner:湖南仁龙新材料有限公司

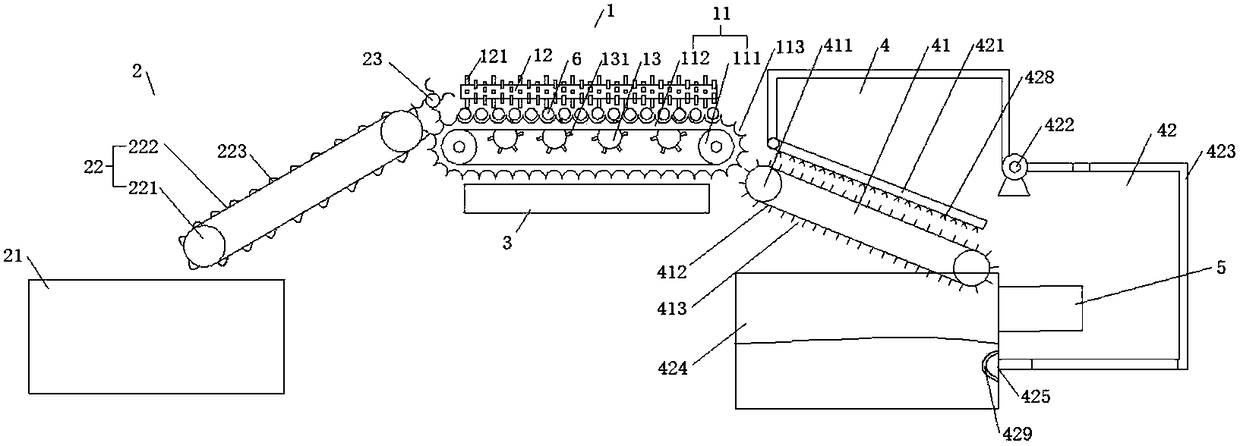

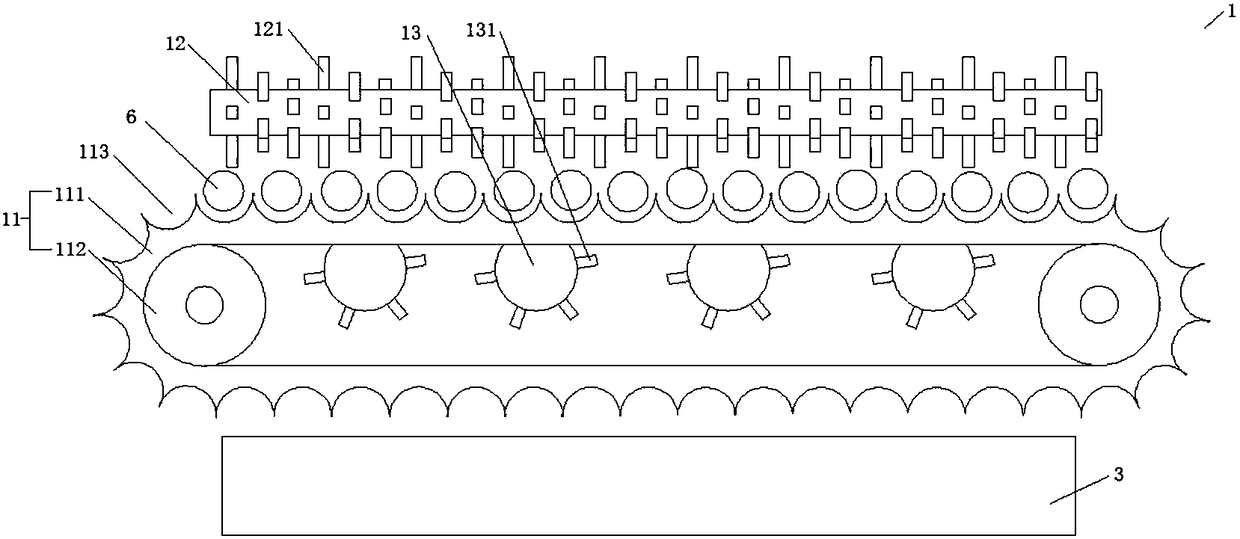

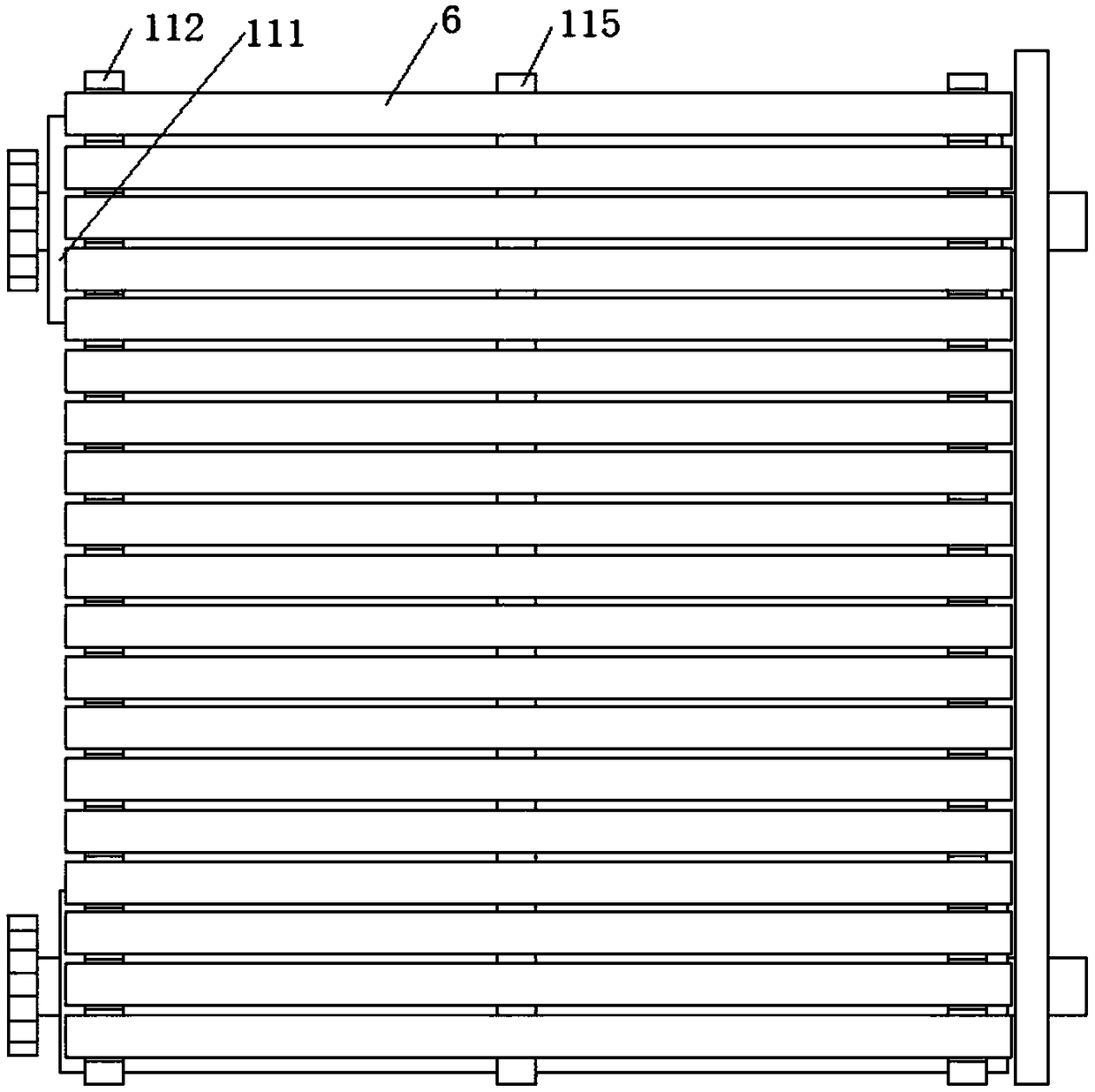

Continuous type sugarcane leaf peeling structure and leaf peeling production line with leaf peeling structure

PendingCN108464112ATo achieve the purpose of stripping cleanPrevent right swipeHarvestersCleaning using toolsProduction lineEngineering

The invention discloses a continuous type sugarcane leaf peeling structure and a leaf peeling production line with the leaf peeling structure, and belongs to the field of agricultural machines. The leaf peeling structure comprises a crawler type conveying device, sugarcane leaf peeling rollers and sugarcane rotary rollers. The sugarcane leaf peeling rollers are evenly distributed above the crawlertype conveying device in the left-right direction, and the axis direction of the sugarcane leaf peeling rollers is the same as the speed direction of the crawler type conveying device. The sugarcanerotary rollers are evenly distributed below the crawler type conveying device in the speed direction, and the axis direction of the sugarcane rotary rollers is perpendicular to the speed direction ofthe crawler type conveying device. The leaf peeling structure has the advantages that sugarcanes are conveyed on the crawler type conveying device, three or more sugarcane leaf peeling rollers are arranged above the crawler type conveying device for leaf peeling in the sugarcane conveying process, the sugarcane rotary rollers are arranged below the crawler type conveying device for rotating the sugarcanes in the leaf peeling process, the different positions of the sugarcanes can all participate in the leaf peeling work of the sugarcane leaf peeling rollers, and the aim of thoroughly peeling off the leaves on the sugarcane stems is achieved.

Owner:NANZHANG COUNTY HUASHENG MACHINERY MFG

Zirconium oxide composite boron nitride refractory product

The invention belongs to the field of a refractory material, and mainly relates to a zirconium oxide composite boron nitride refractory product. A high-purity zirconium oxide refractory material is taken as a main body, a certain ratio of boron nitride is compounded on the work surface within a certain thickness, and a composite layer contains boron nitride, so that the operating temperature of the refractory material can be improved, and the corrosion resistance and the thermal shock resistance are improved; meanwhile, a protective layer can be formed between a hearth and the refractory material, so that cross contamination of the zirconium oxide refractory material and the material inside the hearth is reduced. A backing layer is still made of the high-purity zirconium oxide refractory material, so that the roles of heat preservation, heat insulation and the like are played by using the characteristics that zirconium oxide is heat-resisting, small in heat-conducting coefficient and the like. Zirconium oxide in the composite layer containing boron nitride and zirconium oxide inside the backing layer which does not contain boron nitride are in an overall structure, and are synchronously sintered, zirconium oxide plays a role of a skeleton, and boron nitride in the composite layer is fixed at the periphery of zirconium oxide and tightly connected with the backing layer, so that boron nitride is effectively prevented from being peeled off.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Fabric tactility imitated automotive polypropylene material

The invention relates to a fabric tactility imitated automotive polypropylene material which is characterized by comprising polypropylene, a flexible modified material, lamellar mica powder and flakyglass flakes, wherein the flexible modified material is at least one substance selected from a styrenic thermoplastic elastomer, a block organic silicon material and polyethylene wax. According to theinvention, by adding the styrenic thermoplastic elastomer, the block organic silicon material and the polyethylene wax, soft tactility is given to the polypropylene material; and meanwhile, additionof the lamellar mica powder and flaky glass flake fillers takes an effect of a skeleton, so that a polypropylene base material has a certain texture while obtaining the tactility and a hand feeling iscloser to a fabric hand feeling.

Owner:苏州润佳高分子材料有限公司

Automobile enhanced roof soundproof pad in composite layer structure

InactiveCN104071090AAct as a skeletonSynthetic resin layered productsLaminationUltrasound attenuationEngineering

The invention relates to an automobile enhanced roof soundproof pad in a composite layer structure. The soundproof pad is obtained by combining multiple soundproof material layers through hot-press forming, and the soundproof material layers are bonded by binders, so that the soundproof pad is in a three-layer composite structure or a five-layer composite structure. Compared with the prior art, the soundproof pad disclosed by the invention has the functions of absorption and attenuation for noise, has a better heat insulating effect, and can enhance the structural strength of a roof.

Owner:SHANGHAI XINAN CAR DEADENING FELT

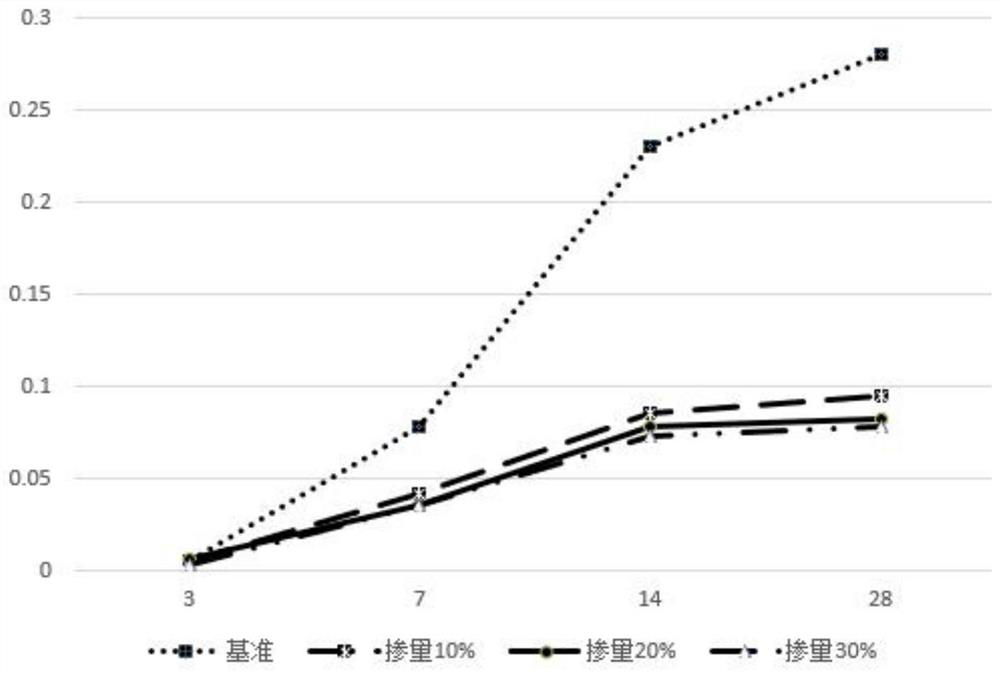

Cement admixture for inhibiting alkali-aggregate reaction, and preparation method thereof

The invention discloses a cement admixture for inhibiting alkali-aggregate reaction. The cement admixture comprises the following components in parts by weight: 30-40 parts of waste glass powder, 15-20 parts of furnace slag, 15-20 parts of mineral slag, 3 parts of wool, 0.3-0.5 part of gelatin, 3-5 parts of alkyl benzene sulfonate sulfate and 10-22 parts of lithium sulfate. The method comprises the following steps: cleaning, airing and grinding waste glass bottles, mixing the waste glass bottles with furnace slag and mineral slag, and performing ball milling to obtain a waste mixture; and uniformly mixing the waste mixture with wool, alkylbenzene sulfonate sulfate, gelatin and lithium sulfate to obtain the cement admixture capable of inhibiting the alkali-aggregate reaction. The preparation process is simple, the use is convenient, the inhibition effect on the alkali aggregate reaction is obvious, the green and environment-friendly effects are realized, and the prepared concrete has excellent performance.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com