Lithium nickel-cobalt-iron positive electrode material and preparation method thereof

A cathode material, lithium cobalt ferrite technology, which is applied in the field of nickel cobalt lithium ferrite cathode material and its preparation, can solve the problems of unstable crystal structure and poor material cycle life, and achieves inhibiting grain growth, low cost, and inhibiting effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

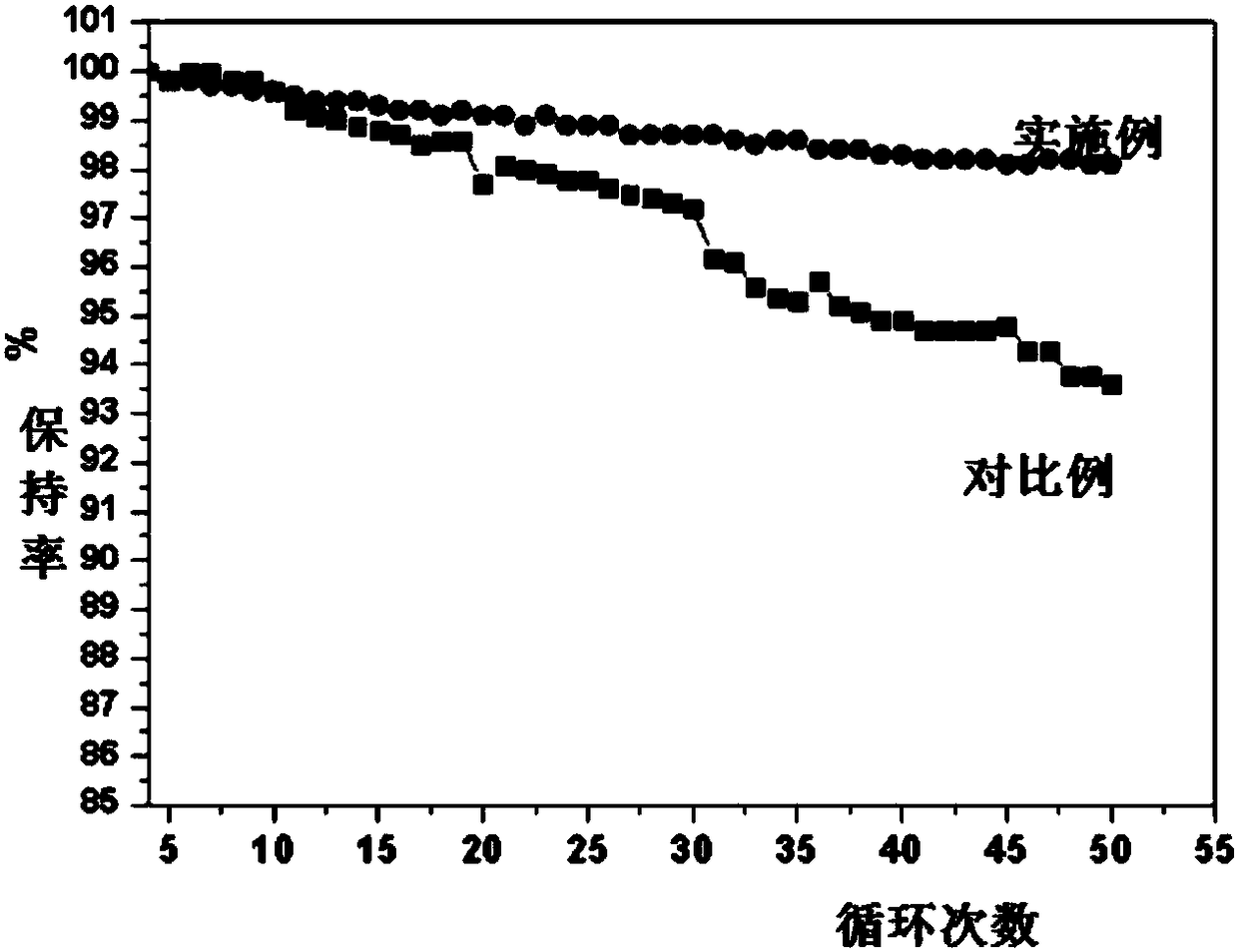

Examples

preparation example Construction

[0023] The preparation method of the nickel-cobalt lithium ferrite cathode material provided by the invention comprises the following steps:

[0024] Step S1, preparing lithium source, nickel source, cobalt source, indium source and iridium source, mixing the lithium source, nickel source and cobalt source evenly to obtain a solid mixture, adding an appropriate amount of distilled water to the solid mixture, and then adding water to dilute A slurry is obtained; in addition, after uniformly mixing the indium source and the iridium source, a certain amount of distilled water is added to continue mixing to obtain a doping solution.

[0025] In this step, the lithium source is lithium carbonate, lithium oxalate or lithium hydroxide, the nickel source is nickel sulfate or nickel oxalate, the cobalt source is cobalt sulfate or cobalt oxalate, and the indium source is indium sulfate or oxalic acid Indium, the iridium source is iridium sulfate or iridium oxalate.

[0026] The liquid-...

Embodiment

[0038] At room temperature, prepare materials according to the molar ratio of lithium hydroxide, nickel sulfate, cobalt sulfate, indium sulfate, and iridium sulfate 1.03:0.8:0.1:0.01:0.01, mix lithium hydroxide, nickel sulfate, and cobalt sulfate evenly, and Add an appropriate amount of distilled water to the solid mixture, wherein the liquid-solid weight ratio of distilled water to the solid mixture is 1.1:1, ball mill and mix for 3 hours; then add water to dilute to obtain a slurry, wherein the liquid-solid weight ratio of the water in the slurry to the solid mixture is 8: 1; Distilled water is mixed with the indium source and the iridium source, and the liquid-solid weight ratio is 150:1.

[0039] Drying the slurry at a temperature of 200°C to obtain a precursor;

[0040] Pre-sintering the precursor to form a microporous structure, spraying the doping solution into the microporous structure through a high-pressure nozzle, and stirring the precursor while spraying;

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com