Automobile sound insulation pad in multi-layer structure and manufacturing method thereof

A multi-layer structure and sound-insulating pad technology, applied in chemical instruments and methods, layered products, vehicle parts, etc., can solve problems such as high cost, heavy weight, and complicated process, and achieve the effect of strengthening overall noise reduction and strengthening absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

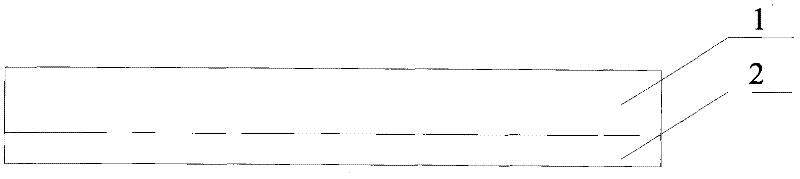

[0017] A method for manufacturing a sound-insulating pad for automobiles with a two-layer structure, the method comprising the following steps:

[0018] (1) Production of high-density sound insulation material: Mix 60kg of fabric, 30kg of melted fiber and 10kg of sponge particles. After combing and netting, place it in an oven and control the temperature at 160°C for heat setting treatment for 4 minutes. Then cut to obtain a density of 220kg / m 3 high-density sound insulation material;

[0019] (2) Control the temperature at 200°C, heat and soften the high-density sound insulation material, place it in a molding mold, and control the pressure at 150bar for mold clamping and pressing for 500s to obtain a layer of uniformly thick and high-density felt hard layer;

[0020] (3) Control the foaming mold temperature to be 55°C, place the high-density felt hard layer in the foaming mold, polyether: the ratio of isocyanate is controlled at 55% to obtain the foaming material, and the t...

Embodiment 2

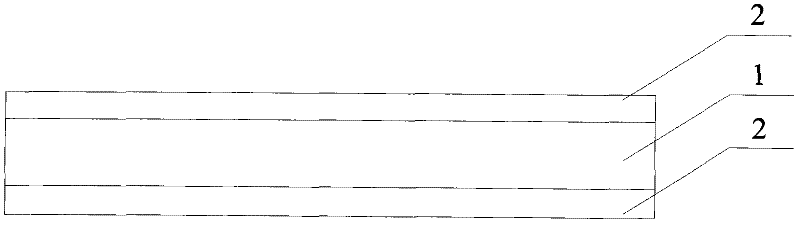

[0022] A method for manufacturing a sound-insulating pad for automobiles with a three-layer structure, the method comprising the following steps:

[0023] (1) Production of high-density sound insulation material: Mix 60kg of fabric, 30kg of melted fiber and 10kg of sponge particles. After combing and netting, place it in an oven and control the temperature at 160°C for heat setting treatment for 4 minutes. Then cut to obtain a density of 220kg / m 3 high-density sound insulation material;

[0024] (2) Control the temperature at 200°C, heat and soften the high-density sound insulation material, place it in a molding mold, and control the pressure at 150bar for mold clamping and pressing for 500s to obtain a layer of uniformly thick and high-density felt hard layer;

[0025] (3) Control the temperature of the foaming mold to be 55° C., place the hard layer of high-density felt in the foaming mold, polyether: the ratio of isocyanate is controlled at 55% to obtain the foaming mater...

Embodiment 3

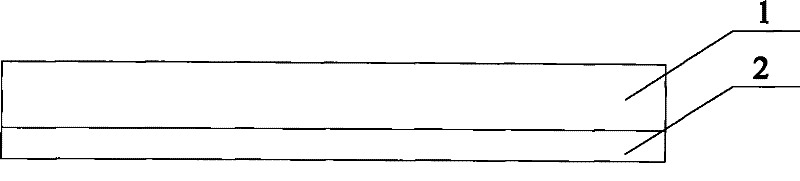

[0028] A method for manufacturing a sound-insulating pad for automobiles with a two-layer structure, the method comprising the following steps:

[0029] (1) Production of low-density sound-insulating materials: Mix 80kg of polyester staple fiber and 20kg of melted fiber, comb and form it into a net, then place it in an oven, control the temperature at 190°C for heat setting for 2 minutes, and then The cutting density is 70kg / m 3 and low-density sound insulation material with a thickness of 15mm;

[0030] (2) Production of high-density sound-insulating hard layer material: control the temperature of the oven at 230°C, place the low-density sound-insulating material in the oven and heat until it is fully softened, then place the low-density sound-insulating material on the forming mold, and the gap between the upper and lower molds of the mold is 5mm, then close the mold immediately, control the pressure at 200bar and press the mold for 150s, then open the mold and take out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com