Antibacterial nano-coating, preparation method thereof, and antibacterial nano-coating cloth

An antibacterial nano-coating and nano-technology, applied in anti-fouling/underwater coatings, devices for coating liquids on surfaces, coatings, etc., can solve problems such as increased production costs, high prices, and reduced market demand for coatings, and achieve reduced Labor intensity, cheap price, and the effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

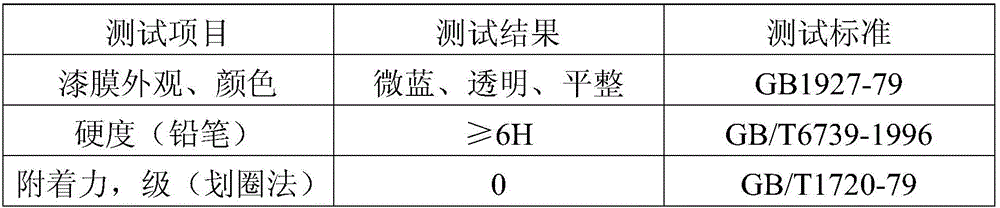

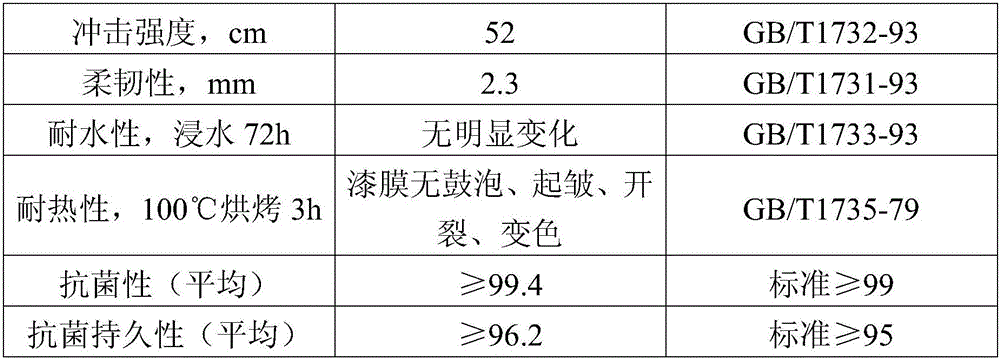

Examples

preparation example Construction

[0032] A preparation method for antibacterial nano-coating, comprising the following specific steps:

[0033] 1), prepare four kinds of nano dispersions

[0034] a. Add the deionized water and the wetting and dispersing agent of the component amount sequentially (by weight percentage) and stir evenly, and slowly add the nano powder while stirring;

[0035]b. After the powder is added, disperse at high speed for 30 minutes, turn on the nano-grinder, carry out circular grinding, and take samples at intervals for inspection. When the median particle size (D50) is between 40 and 80 nm, stop the machine to obtain nano-slurry and nano-dispersion The particle size distribution is uniform and very stable, with a long shelf life at room temperature and good compatibility with most film-forming substances;

[0036] 2), preparation of antibacterial nano coating

[0037] a, the nano-rice husk-nano-silver dispersion, nano-ATO dispersion, nano-LaB prepared in step 1) 6 Dispersion, Nano W...

Embodiment 1

[0042] A preparation method for antibacterial nano-coating, comprising the following specific steps:

[0043] 1), preparation of nano-dispersion

[0044] a. The preparation process of nano-ATO dispersion is as follows: 66% deionized water, 2% wetting and dispersing agent (T90), 7% wetting and dispersing agent (AFCONA4560), 25% nano-ATO powder, and deionized components are added in sequence Water, wetting and dispersing agent and stirring evenly, then slowly add nano powder while stirring, after the powder is added, disperse at high speed for 30 minutes, turn on the nano grinder, and carry out circular grinding, the grinding time is about 13-15 hours, and the median Nano-ATO dispersion with a particle size of about 75nm and a solid content of 25%;

[0045] b. The preparation process of nano-rice husk-nano-silver dispersion is as follows: deionized water 64%, wetting and dispersing agent (BYK90) 2%, wetting and dispersing agent (AFCONA4560) 7%, nano-rice husk-nano-silver powder...

Embodiment 2

[0053] The steps of this example are the same as the preparation process of Example 1, and the proportioning ratio of each component of the antibacterial nano-coating is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com