Method for producing petuntse from waste ceramics

A technology for waste ceramics and porcelain mud, applied in the field of ceramics, can solve the problems of unutilized and popularized waste ceramics, and achieve the effects of reducing the types of components, saving production costs, and having good plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

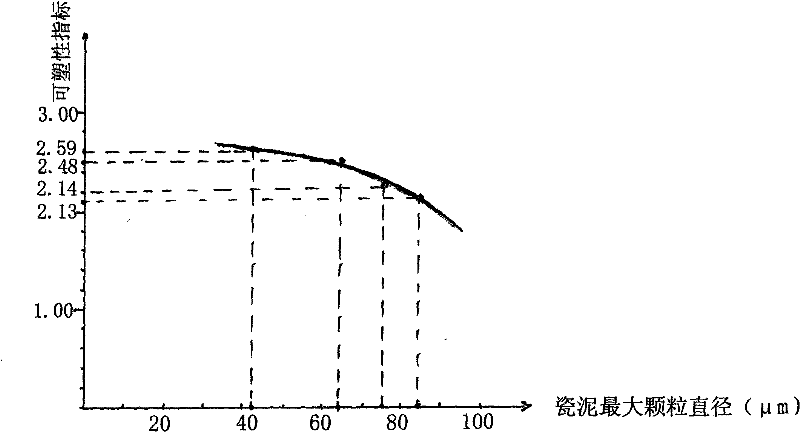

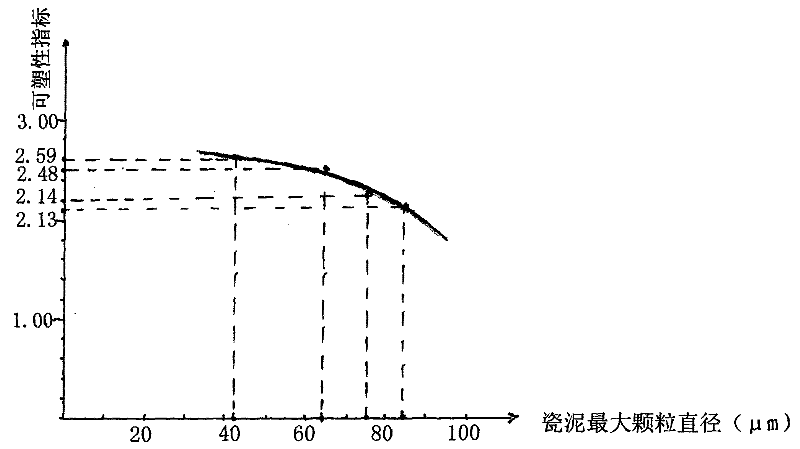

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below through examples.

[0021] Take waste ceramics, crush and ball mill, and then sieve to make waste ceramic particles with a fineness of ≤50 μm for later use; by weight of waste ceramics 45%, quartz 8%, feldspar 10%, machine mud 15%, kaolin 22% Percentage Quartz, feldspar, machine mud, kaolin and the above-mentioned spare waste ceramic particles are mixed and put into a ball mill, mixed and ball milled for 30 hours to make mud, and the fineness of the ball mill is controlled to be less than 0.2% after passing through a 325 mesh sieve; After the above mud is screened, iron-removed, press-filtered and mud-smelted, porcelain clay is obtained.

[0022] Use the porcelain clay prepared above to produce decorative art ceramics. The porcelain clay has good plasticity, and the cracking and damage of the body formed by grouting is less than 5%; it is fired in the temperature range of 1230-1250 ° C, the firing condition is good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com