Solid sulfur ash masonry mortar

A technology for masonry mortar and sulfur-fixing ash is applied in the field of mortar composition to achieve the effects of cost reduction, energy saving and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

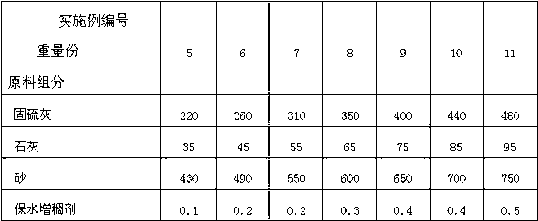

Examples

Embodiment 1

[0020] A sulfur-fixing ash masonry mortar, the raw material components and the weight ratio include: 313 parts by weight of sulfur-fixing ash, 61 parts by weight of quicklime, 626 parts by weight of sand, and 0.1 part by weight of a water-retaining thickener.

[0021] Among them: the sulfur-fixed ash is the sulfur-fixed ash discharged from the power plant, which is ground into a fine powder with a sieve residue of 0.045mm and less than 10%; the sand particle size is controlled at 20-70 mesh.

[0022] The preparation method of sulfur-fixing ash masonry mortar is: after mixing the components according to the above weight ratio, add water and mix well according to the water-material ratio of 0.216 (that is, adjust to a consistency of 70-90mm), and then prepare the sulfur-fixing ash masonry mortar Mortar, which can be used for post-building construction.

[0023] The basic properties of the sulfur-fixed ash masonry mortar are: water retention rate of 94.1%, 28d compressive strengt...

Embodiment 2

[0025] A sulfur-fixing ash masonry mortar, the raw material components and the weight ratio include: 455 parts by weight of sulfur-fixing ash, 90 parts by weight of quicklime, 455 parts by weight of sand, and 0.1 part by weight of a water-retaining thickener.

[0026] Among them: the sulfur-fixed ash is the sulfur-fixed ash discharged from the power plant, which is ground into a fine powder with a sieve residue of 0.045mm and less than 10%; the sand particle size is controlled at 20-70 mesh.

[0027] The preparation method of the sulfur-fixing ash masonry mortar is: after mixing the components according to the above weight ratio, add water and mix well according to the water-material ratio of 0.324 (that is, adjust to a consistency of 70-90mm), and then prepare the sulfur-fixing ash masonry mortar Mortar, which can be used for post-building construction.

[0028] The basic properties of the sulfur-fixed ash masonry mortar are: water retention rate of 90.4%, 28d compressive str...

Embodiment 3

[0030] A sulfur-fixing ash masonry mortar, the raw material components and weight proportions include: 323 parts by weight of sulfur-fixing ash, 31 parts by weight of slaked lime, 646 parts by weight of sand, and 0.1 part by weight of a water-retaining thickener.

[0031] Among them: the sulfur-fixed ash is the sulfur-fixed ash discharged from the power plant, which is ground into a fine powder with a sieve residue of 0.045mm and less than 10%; the sand particle size is controlled at 20-70 mesh.

[0032] The preparation method of the sulfur-fixing ash masonry mortar is: after mixing the components according to the above weight ratio, add water and mix well according to the water-material ratio of 0.324 (that is, adjust to a consistency of 70-90mm), and then prepare the sulfur-fixing ash masonry mortar Mortar, which can be used for post-building construction.

[0033] The basic properties of the sulfur-fixed ash masonry mortar are: water retention rate of 94.2%, 28d compressive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com