High-specific-capacitance manganese-dioxide conducting polymer composite electrode material with core-shell structure and manufacturing method thereof

A technology of conductive polymer and manganese dioxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of limiting the practical application of supercapacitor electrode materials, poor cycle stability, and difficulty in meeting demands, and achieves Good cycle stability, improved conductivity, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

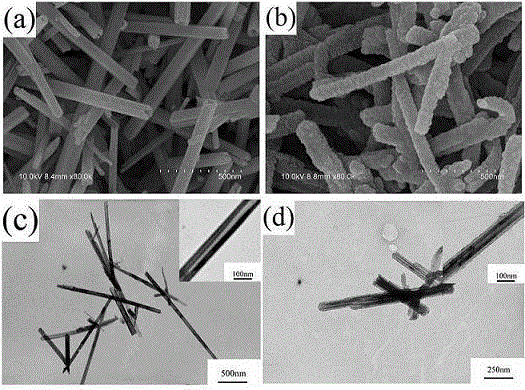

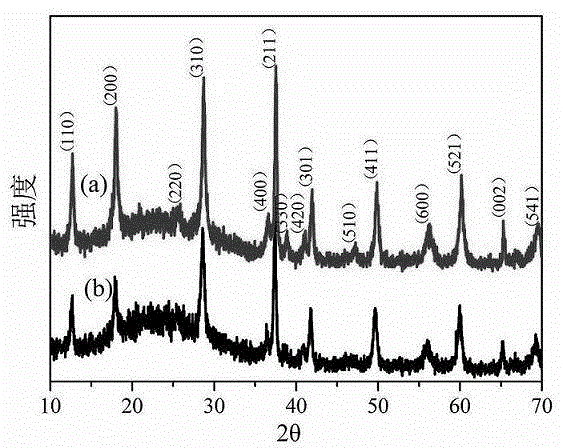

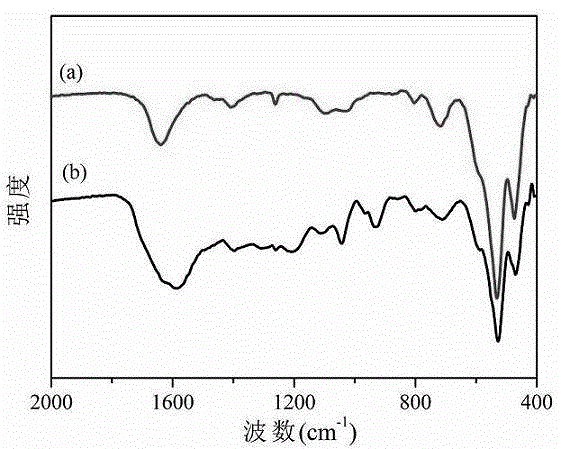

[0033] Embodiment 1. Preparation of a core-shell structure composite electrode material with manganese dioxide nanotubes as the core and polypyrrole as the shell.

[0034] Dissolve 0.307g of potassium permanganate and 0.65ml of concentrated hydrochloric acid in 35ml of distilled water, and conduct a hydrothermal reaction at 140° C. for 12 hours in a 50ml hydrothermal kettle, thereby obtaining manganese dioxide nanotubes. Disperse 150mg of manganese dioxide nanotubes into 60ml of 0.01M sulfuric acid and stir slowly at 25°C. Another 100 μL of pyrrole monomer was dispersed into 40 ml of 0.01M sulfuric acid, and the pyrrole solution was quickly added to the manganese dioxide dispersion, and reacted at 25°C for 180mins to obtain a core-shell structure manganese dioxide-polypyrrole composite electrode material.

[0035] Electrochemical tests show that when the scan rate is 1mV / s, the specific capacitance of this core-shell structure manganese dioxide polypyrrole composite electrode ...

Embodiment 2

[0036] Example 2. Preparation of a core-shell structure composite electrode material with manganese dioxide nanospheres as the core and poly(3,4-ethylenedioxythiophene) as the shell.

[0037]Dissolve 0.5 g of potassium permanganate and 2 ml of concentrated sulfuric acid in 70 ml of distilled water, and conduct a hydrothermal reaction at 180° C. for 12 hours in an 80 ml hydrothermal kettle, thereby obtaining manganese dioxide nanospheres. Disperse 50mg of manganese dioxide nanospheres into 30ml of 0.001M hydrochloric acid, and stir slowly at 25°C. Disperse 50 μL of 3,4-ethylenedioxythiophene monomer into 70 ml of 0.001M benzoic acid, quickly add the 3,4-ethylenedioxythiophene dispersion into the manganese dioxide dispersion, and react at 25°C After 180 mins, the core-shell structure manganese dioxide poly(3,4-ethylenedioxythiophene) composite electrode material was obtained.

[0038] Electrochemical tests show that when the scan rate is 1mV / s, the specific capacitance of this...

Embodiment 3

[0039] Example 3. Preparation of a core-shell composite electrode material with manganese dioxide nanowires as the core and polyaniline as the shell.

[0040] Dissolve 0.307g of potassium permanganate and 0.65ml of concentrated nitric acid in 35ml of distilled water, and conduct a hydrothermal reaction at 140° C. for 12 hours in a 50ml hydrothermal kettle, thereby obtaining manganese dioxide nanowires. Disperse 150mg of manganese dioxide nanowires into 80ml of 1M naphthalene disulfonic acid and stir slowly at 25°C. Disperse 100 μL of aniline monomer into 20 ml of 1M acetic acid, quickly add the aniline solution into the manganese dioxide dispersion, and react at 25°C for 180mins to obtain a core-shell structure manganese dioxide-polyaniline composite electrode material.

[0041] Electrochemical tests show that when the scan rate is 1mV / s, the specific capacitance of this core-shell structure manganese dioxide polypyrrole composite electrode material can reach 400F / g; cycle 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com