Radiation-resistant putty powder

A putty powder and anti-radiation technology, which is applied in the field of putty powder for interior walls and anti-radiation putty powder, can solve the problems of poor stain resistance of elastic coatings, and achieve the effects of excellent washing resistance, excellent moisture resistance, and excellent radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

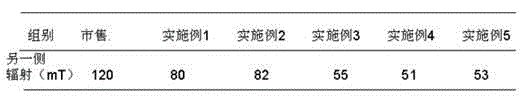

Examples

Embodiment 1

[0018] A kind of anti-radiation putty powder, comprises the raw material of following parts by weight: 30 parts of heavy calcium carbonate powder, 30 parts of ash calcium powder, 5 parts of hydroxypropyl methylcellulose, 5 parts of lignocellulose, 0.5 part of phenol cyanine blue, 0.2 parts of iron yellow, 1 part of diatomaceous earth, 2 parts of lightly burned magnesia, 1 part of barium, 3 parts of cadmium, 2 parts of tin, 3 parts of yeast powder, and 2 parts of lactic acid bacteria powder.

Embodiment 2

[0020] A kind of anti-radiation putty powder, comprising the following raw materials in parts by weight: 50 parts of heavy calcium carbonate powder, 50 parts of gray calcium powder, 15 parts of hydroxypropyl methylcellulose, 10 parts of lignocellulose, 1 part of phenol cyanine green, 0.5 parts of titanium dioxide, 0.5 parts of transparent iron oxide, 5 parts of diatomaceous earth, 7 parts of lightly burned magnesia, 1 part of barium, 3 parts of cadmium, 5 parts of tin, 2 parts of yeast powder, and 3 parts of lactic acid bacteria powder.

Embodiment 3

[0022] A radiation-proof putty powder, comprising the following raw materials in parts by weight: 35 parts of heavy calcium carbonate powder, 35 parts of gray calcium powder, 12 parts of hydroxypropyl methylcellulose, 12 parts of wood cellulose, 1 part of iron yellow, silicon 2 parts of algae earth, 4 parts of lightly burned magnesia, 1 part of barium, 2 parts of cadmium, 4 parts of tin, 1 part of yeast powder, and 3 parts of lactic acid bacteria powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com