Multi-layer sound insulation pad for automobile and manufacture method thereof

A technology of multi-layer structure and manufacturing method, applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of high cost, heavy weight, complicated process, etc., and achieve the effect of strengthening the overall noise reduction and strengthening absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

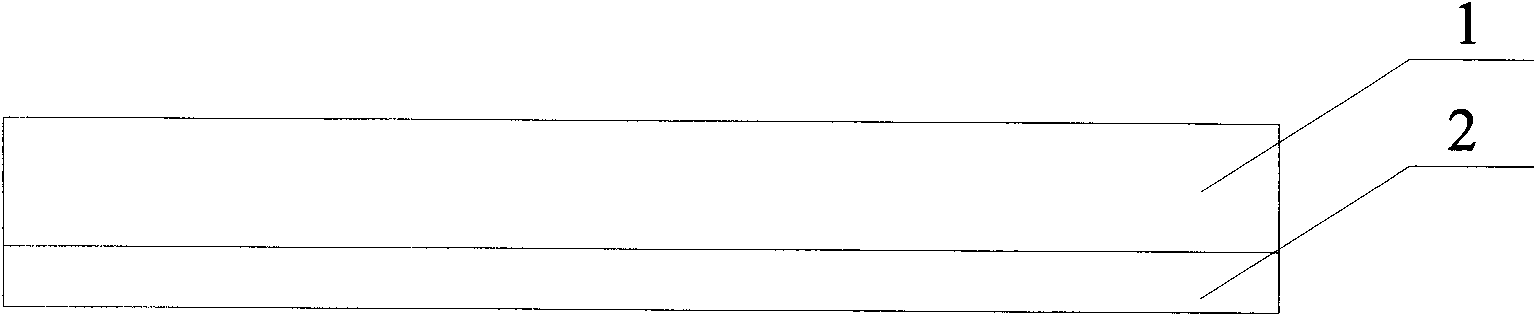

Embodiment 1

[0020] A method for manufacturing a sound-insulating pad for automobiles with a two-layer structure, the method comprising the following steps:

[0021] (1) Production of low-density sound-insulating materials: Mix 60kg of flower cloth, 30kg of composite polyester fiber and 10kg of sponge particles. After combing and netting, place it in an oven and control the temperature at 200°C for heat setting treatment for 4 minutes. , and then cut to obtain a density of 220kg / m 3 high-density sound insulation material;

[0022] (2) Production of high-density sound-insulating materials: Mix 70kg of polyester staple fibers and 30kg of composite polyester fibers. After combing and netting, place them in an oven, control the temperature at 160°C for 4 minutes, and then After cutting, the density is 70kg / m 3 Low-density sound insulation materials;

[0023] (3) Control the temperature of the oven at 200°C, place the low-density sound-insulating material and the high-density sound-insulatin...

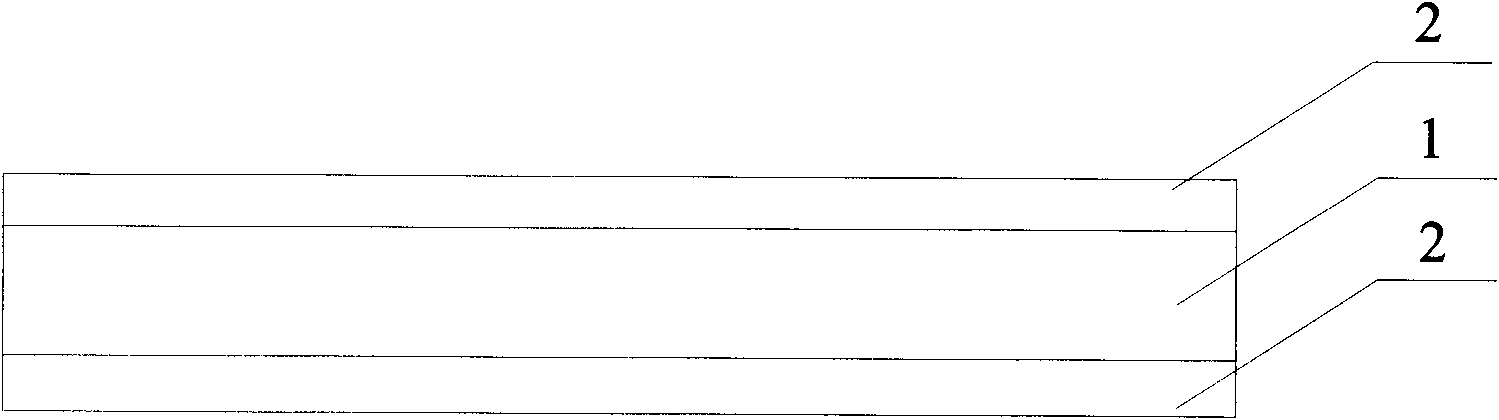

Embodiment 2

[0025] A method for manufacturing a sound-insulating pad for automobiles with a three-layer structure, the method comprising the following steps:

[0026] (1) Production of low-density sound-insulating materials: Mix 60kg of flower cloth, 30kg of composite polyester fiber and 10kg of sponge particles. After combing and netting, place it in an oven and control the temperature at 200°C for heat setting treatment for 4 minutes. , and then cut to obtain a density of 220kg / m 3 high-density sound insulation material;

[0027] (2) Production of high-density sound-insulating materials: Mix 70kg of polyester staple fibers and 30kg of composite polyester fibers. After combing and netting, place them in an oven, control the temperature at 160°C for 4 minutes, and then After cutting, the density is 70kg / m 3 Low-density sound insulation materials;

[0028] (3) Control the temperature of the oven at 200°C, place the low-density sound-insulating material and the high-density sound-insulat...

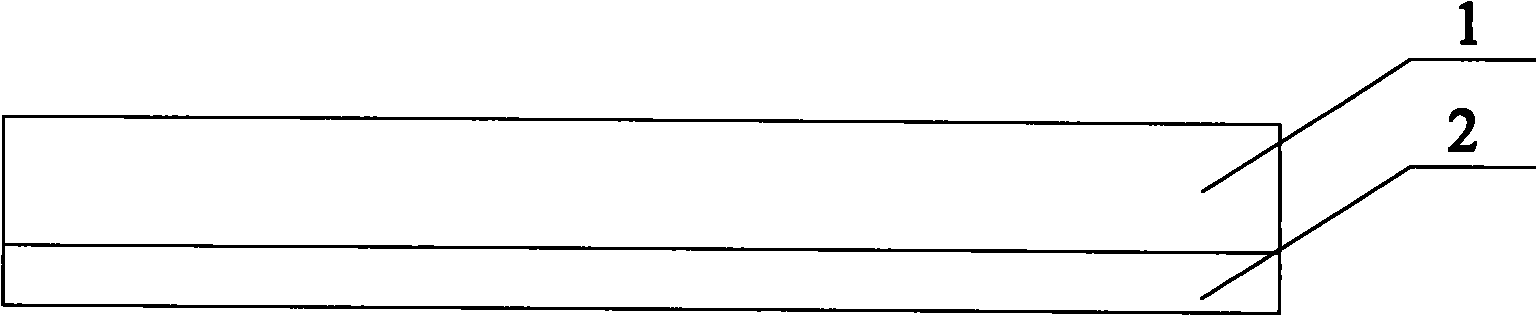

Embodiment 3

[0030] A method for manufacturing a sound-insulating pad for automobiles with a two-layer structure, the method comprising the following steps:

[0031] (1) Production of low-density sound insulation materials: Mix 80kg of fabric, 20kg of composite polypropylene fiber and 5kg of sponge particles. After combing and netting, place it in an oven and control the temperature at 210°C for heat setting treatment for 2 minutes. , and then cut to obtain a density of 200kg / m 3 high-density sound insulation material;

[0032] (2) Production of high-density sound-insulating materials: Mix 80kg of polyester staple fiber and 20kg of composite polypropylene fiber. After combing and netting, place it in an oven, control the temperature at 190°C for heat setting treatment for 2 minutes, and then After cutting, the density is 150kg / m 3 Low-density sound insulation materials;

[0033] (3) Control the temperature of the oven at 220°C, place the low-density sound insulation material and the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com