Method for manufacturing organic and inorganic perovskite crystal film

An inorganic calcium and titanium ore technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as reducing the efficiency of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

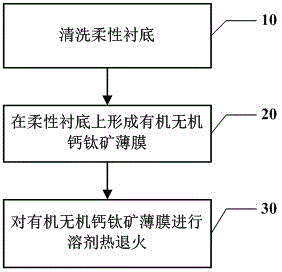

[0021] The specific steps of the method for manufacturing an organic-inorganic perovskite crystal thin film according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] Such as figure 1 As shown, in one embodiment of the present invention, in step 10, the flexible substrate is cleaned first. In some embodiments of the present invention, the flexible substrate can be made of polyethylene terephthalate (PET), polyethylene naphthalate ( PEN) or polyimide (PI) flexible substrates. In the process of cleaning the flexible substrate, the flexible substrate can be cleaned with detergent water, acetone, absolute ethanol and deionized water for 15 minutes in sequence, and then the flexible substrate is dried.

[0023] After cleaning the flexible substrate, in step 20, an organic-inorganic perovskite film can be formed on the flexible substrate.

[0024] In one embodiment, organic-inorganic perovskite films...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com