Graphene oxide modified polymer gel electrolyte and sodium metal battery

A gel electrolyte, graphene modification technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolytes, etc., can solve problems such as hindering ion transmission paths and unsatisfactory ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

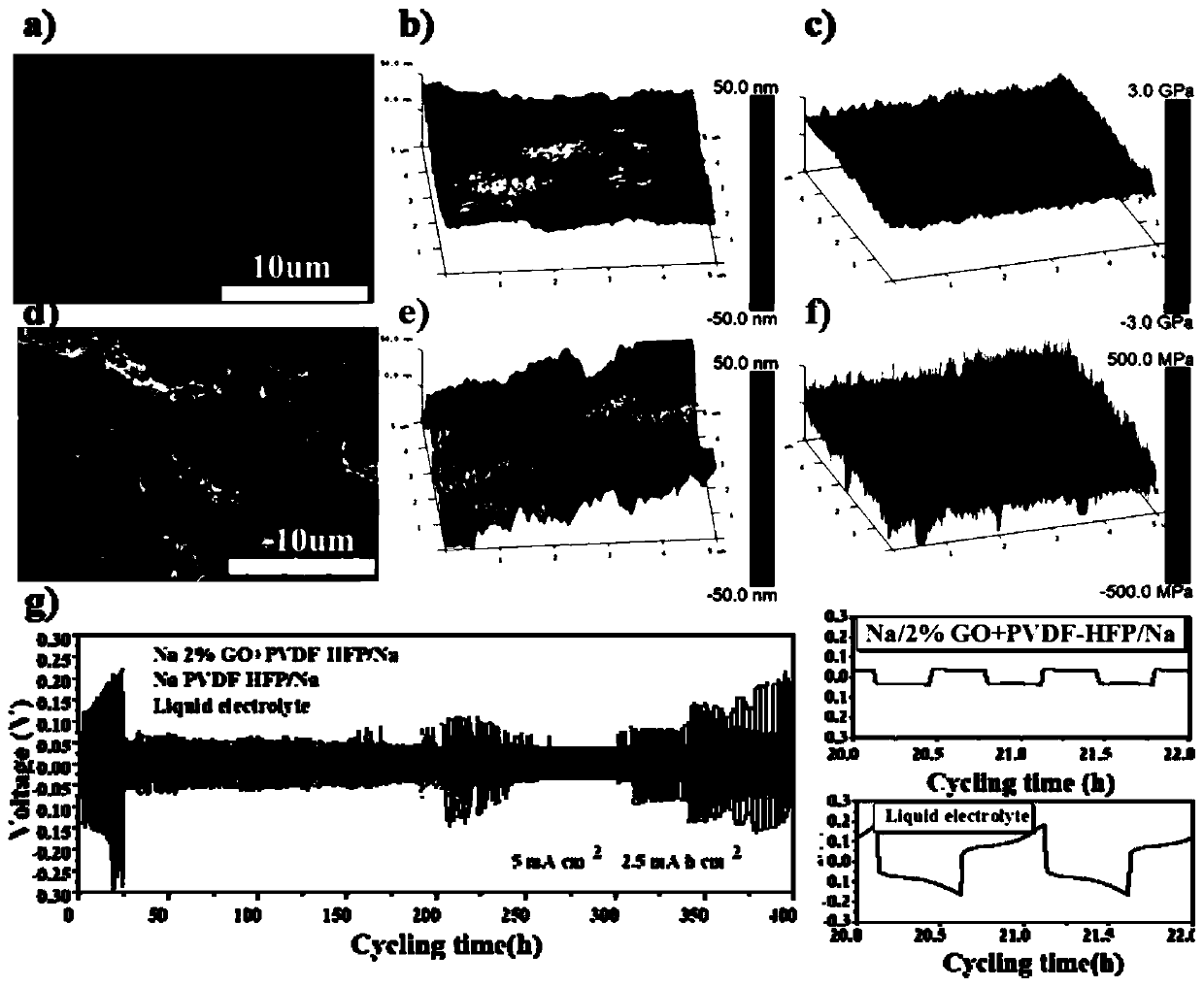

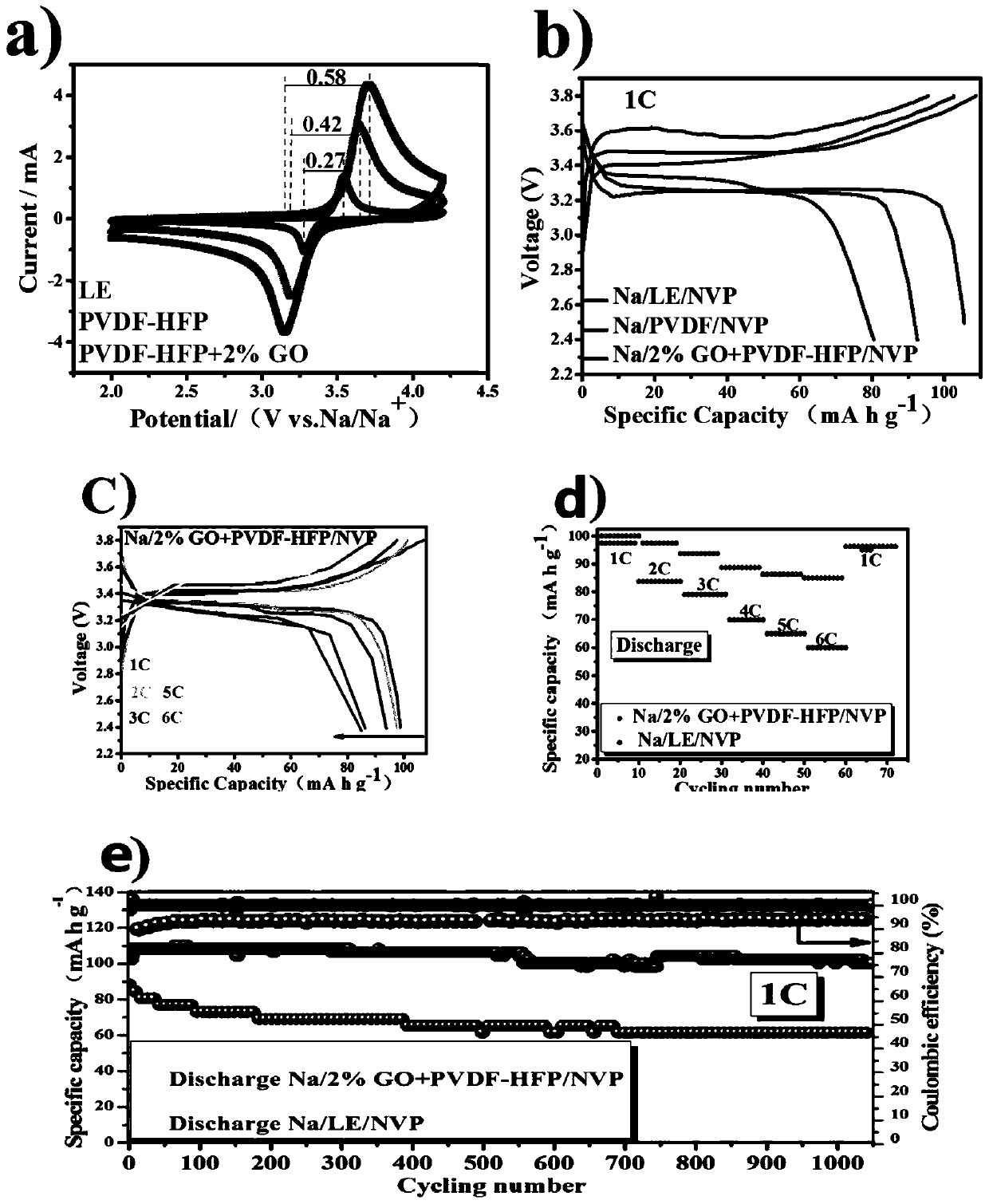

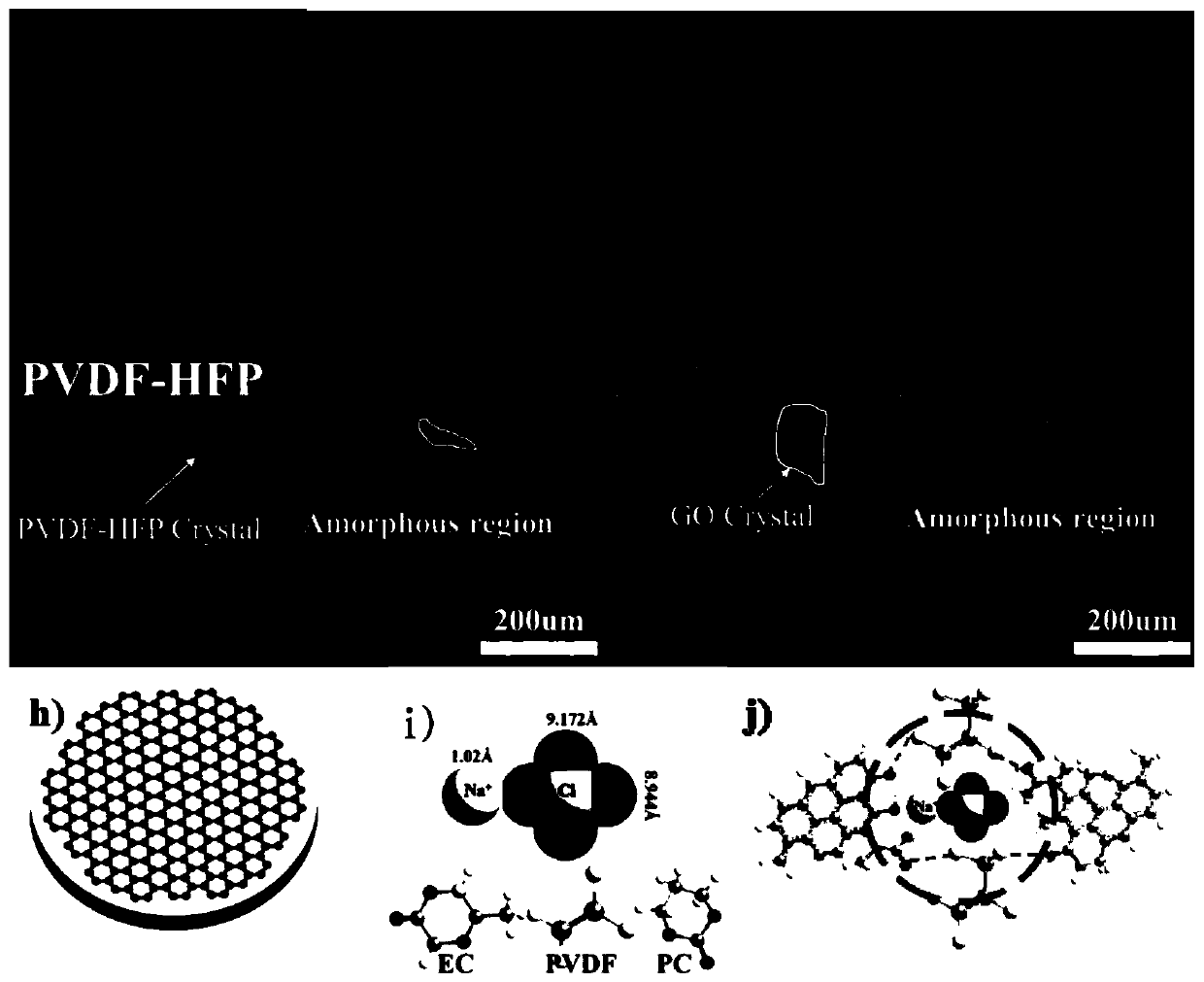

Method used

Image

Examples

preparation example Construction

[0022]The sodium salt is selected from sodium hexafluorophosphate, sodium borohydride, sodium carbonate, sodium bicarbonate, sodium chloride, sodium fluoride, sodium sulfate, sodium phosphate, sodium nitrate, sodium difluorooxalate borate, sodium pyrophosphate, Sodium dodecylbenzene sulfonate, sodium lauryl sulfate, sodium citrate, sodium metaborate, sodium borate, sodium molybdate, sodium tungstate, sodium bromide, sodium nitrite, sodium iodate, sodium iodide , sodium silicate, sodium lignosulfonate, sodium oxalate, sodium aluminate, sodium methanesulfonate, sodium acetate, sodium dichromate, sodium hexafluoroarsenate, sodium tetrafluoroborate, sodium perchlorate or trifluoro One or more of sodium methanesulfonylimide. The additive is at least one of glycerin, sodium citrate, sodium polystyrene sulfonate, sodium iminosuccinate and polyethylene glycol. The non-aqueous solvent is selected from acetone, propylene carbonate, ethylene carbonate, diethyl carbonate, dimethyl carbon...

Embodiment 1

[0026] This embodiment provides a graphene oxide modified polymer gel electrolyte made of the following components by weight: 50 parts of polyvinylidene fluoride-hexafluoropropylene, 1 part of graphene oxide, and 5 parts of sodium hexafluorophosphate , 20 parts of acetone, 0.5 parts of glycerin, and 3 parts of absolute ethanol.

[0027] The preparation method of the graphene oxide modified polymer gel electrolyte comprises the steps of: dissolving polyvinylidene fluoride-hexafluoropropylene in acetone, stirring for 3 hours, and at the same time adding graphene oxide to absolute ethanol Ultrasonic dispersion in medium for 2 hours; then pour the dissolved polyvinylidene fluoride-hexafluoropropylene and graphene oxide dispersed in ultrasound together, and add sodium hexafluorophosphate and glycerin according to the proportion, blend and stir for 3 hours; the stirring is over Finally, evenly pour the mixed jelly on a clean glass plate to level it; then immediately put it into a va...

Embodiment 2

[0030] This embodiment provides a graphene oxide modified polymer gel electrolyte, which is made of the following components by weight: 53 parts of polyvinylidene fluoride-hexafluoropropylene, 2 parts of graphene oxide, dodecylbenzenesulfonate 6.5 parts of sodium bicarbonate, 25 parts of fluoroethylene carbonate, 1.5 parts of sodium polystyrene sulfonate, and 4 parts of absolute ethanol.

[0031] The preparation method of the graphene oxide modified polymer gel electrolyte comprises the steps of: dissolving polyvinylidene fluoride-hexafluoropropylene in fluoroethylene carbonate, stirring for 3.5 hours, and at the same time adding graphene oxide Ultrasonic dispersion in absolute ethanol for 2.3 hours; then pour the dissolved polyvinylidene fluoride-hexafluoropropylene and ultrasonically dispersed graphene oxide together, and add sodium dodecylbenzenesulfonate and polyphenylene sulfonate according to the proportion Sodium ethylene sulfonate, blended and stirred for 3.5 hours; af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com