Color adjustable perovskite LED based on micro-nano structure and preparation method thereof

A micro-nano structure, perovskite technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as uncontrollable color, achieve simple structure, high ambipolar carrier transport properties, Guaranteed effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

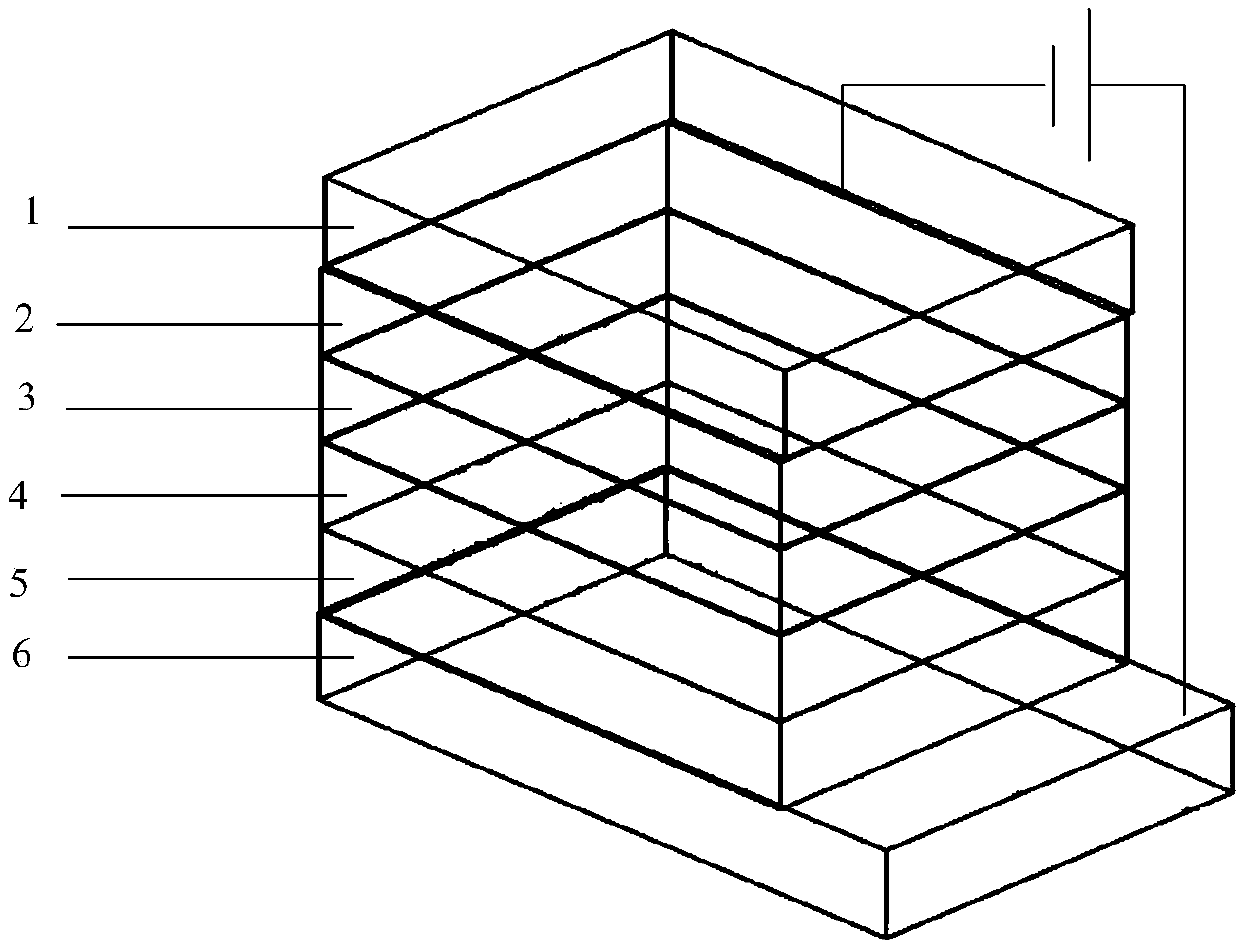

[0053] This embodiment provides an overall device structure of a color-tunable perovskite LED based on a micro-nano structure.

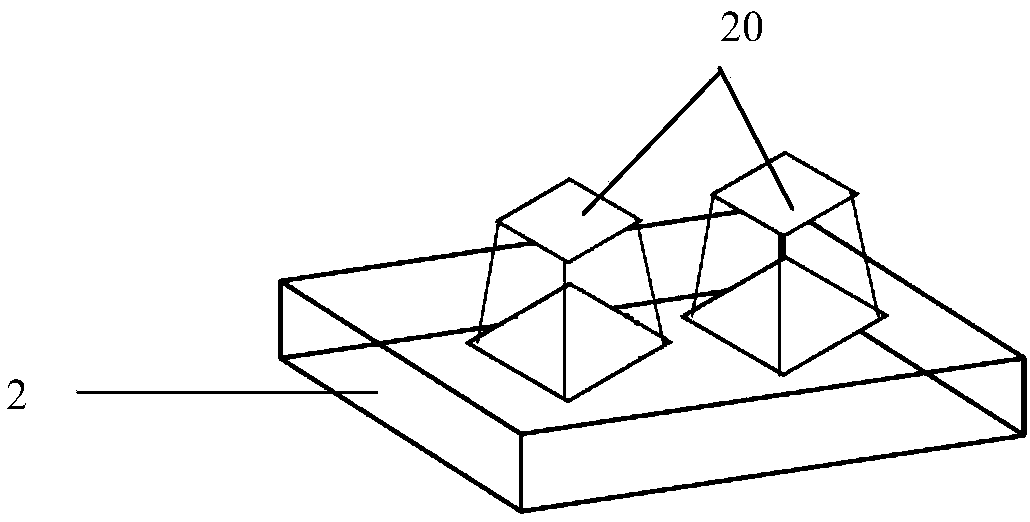

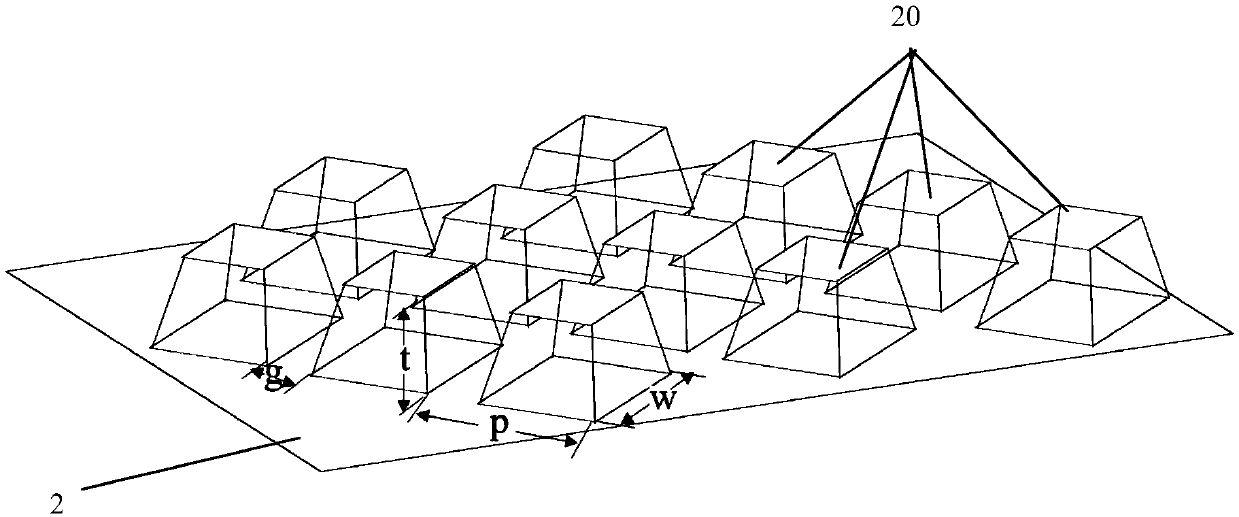

[0054] Such as figure 1 The overall structure of a color-tunable perovskite LED device based on micro-nano structure is shown, from bottom to top are indium tin oxide (ITO) layer 1, titanium dioxide (TiO2) layer 2, styrene sulfonate ( PEDOT:PSS) layer 3, perovskite (perovskite) layer 4, 1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl)benzene (TPBi) layer 5, lithium fluoride ( LiF) / aluminum (AL) layer 6.

[0055] In terms of thickness design, the thickness of the indium tin oxide layer 1 is 13nm, the thickness of the titanium dioxide layer 2 is 230nm, the thickness of the styrene sulfonate layer 3 is 40nm, and the thickness of the perovskite layer 4 is 120nm, 1,3,5 - The thickness of the tris(1-phenyl-1H-benzimidazol-2-yl)benzene layer 5 is 40 nm, and the thickness of the lithium fluoride / aluminum layer 6 is 1 nm for the lithium fluoride layer and 100 nm ...

Embodiment 2

[0060] This embodiment provides a method for preparing the monolithic device described in Embodiment 1.

Embodiment approach

[0061] Concrete implementation scheme is as follows:

[0062] (1) Preparation of titanium dioxide layer: use a commercial 15nm thick ITO glass substrate, soak it in acetone and isopropanol in an ultrasonic cleaner for 10 minutes, take it out and dry it with clean nitrogen, and put it in the plasma Clean in a body cleaner for 10 minutes and improve the adhesion between the photoresist and the substrate. After that, a ZEP520 photoresist film with a thickness of 350nm was covered on the surface of the ITO glass substrate by spin coating, and then kept on a glue baking table at 180°C for one hour. Afterwards, the sample was subjected to pattern exposure (30kV) by an electron beam exposure system, and after taking it out, it was developed in ND510 developer solution at 0°C for 60 seconds, so that the ZEP520 photoresist formed a nanostructure. After developing and drying with clean nitrogen, the sample was transferred to the vacuum chamber of the electron beam evaporation system. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com