Rare earth hydride surface coating treating agent, application thereof and method for forming rare earth hydride surface coating

A rare earth hydride and surface coating technology, applied in the field of surface coating treatment agent, rare earth hydride surface coating treatment agent and its surface coating formation, can solve the problem of magnet remanence and magnetic energy product decrease, loss of magnet saturation magnetization Strength, scarcity of resources and other issues, to achieve the effect of improving coercivity, improving magnetic properties, and large diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

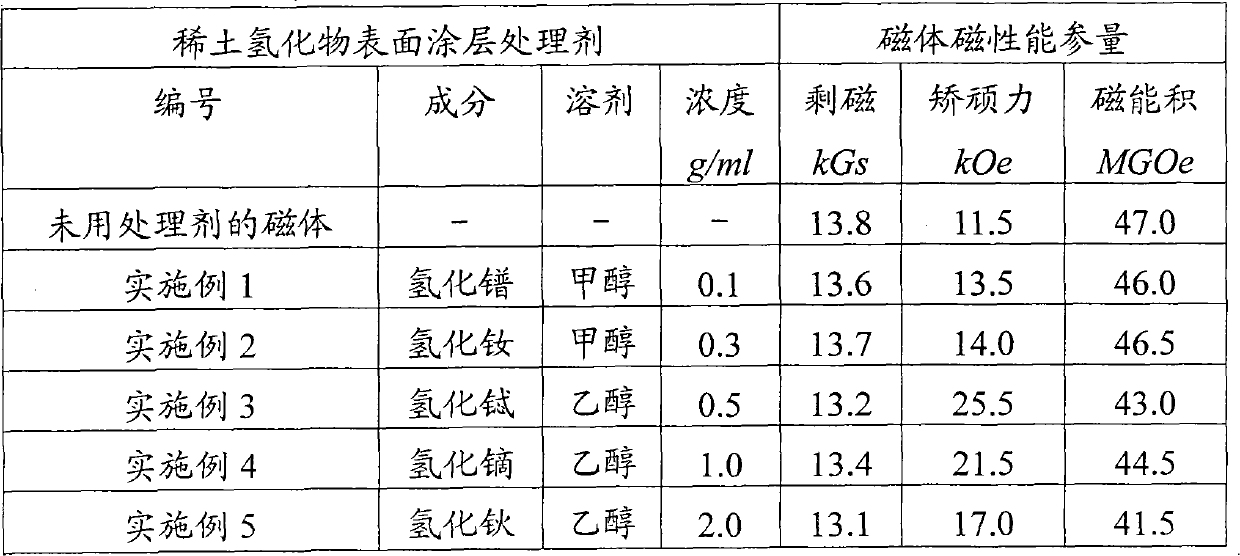

[0013] Mix 10 g of rare earth praseodymium hydride nanoparticles with an average particle diameter of 10 nanometers and 100 ml of methanol, so that praseodymium hydride is uniformly dispersed in methanol, and prepare a treatment agent for forming a surface coating of praseodymium hydride. The concentration is 0.1 g / ml.

[0014] The sintered NdFeB magnet (see the No. 1 magnet in Table 1 for its magnetic properties) was prepared into a small block with an outer dimension of 7×7×7 mm, and its surface was polished. The treated magnet was immersed in the praseodymium hydride surface coating treatment agent, subjected to ultrasonic treatment for 1 minute, and then air-dried, so that the methanol in the surface coating of the magnet was volatilized. Finally, place the air-dried magnet in a vacuum of 1 x 10 -5 Heat treatment was performed at 550° C. for 2 hours in a heat treatment furnace in Torres. The final magnetic performance parameters of the magnet after treatment are shown i...

Embodiment 2

[0016] Mix 30 g of rare earth NdH nanoparticles with an average particle diameter of 20 nanometers and 100 ml of methanol to uniformly disperse NdH in methanol to prepare a treatment agent for forming a NdH surface coating with a concentration of 0.3 g / ml.

[0017] The sintered NdFeB magnet was prepared into a small piece with an outer dimension of 7×7×7 mm, and its surface was polished. The treated magnet was immersed in the neodymium hydride surface coating treatment agent, subjected to ultrasonic treatment for 1 minute, and then air-dried to make the methanol in the surface coating of the magnet volatilize. Finally, place the air-dried magnet in a vacuum of 1 x 10 -5 Heat treatment was performed at 600°C for 1.5 hours in a heat treatment furnace in Torre. The final magnetic performance parameters of the magnet after treatment are shown in the No. 3 magnet in Table 1.

Embodiment 3

[0019] Mix 50 g of rare earth terbium hydride nanoparticles with an average particle diameter of 100 nanometers and 100 ml of ethanol evenly, so that praseodymium hydride is uniformly dispersed in ethanol, and a treatment agent for forming a surface coating of praseodymium hydride is prepared, and its concentration is 0.5 g / ml.

[0020] The sintered NdFeB magnet (see the No. 1 magnet in Table 1 for its magnetic properties) was prepared into a small block with an outer dimension of 7×7×7 mm, and its surface was polished. The treated magnet was immersed in the terbium hydride surface coating treatment agent, subjected to ultrasonic treatment for 1 minute, and then air-dried to make the ethanol in the magnet surface coating volatilize. Finally, place the air-dried magnet in a vacuum of 1 x 10 -5 Heat treatment was performed at 850°C for 1 hour in a heat treatment furnace in Torres. The final magnetic performance parameters of the magnet after treatment are shown in the No. 3 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com