Composite nanometer structure and production method thereof

A composite nanostructure and nanocrystal technology, applied in the direction of nanotechnology, nanotechnology, nano-optics, etc., can solve the problems of serious surface defects, unfavorable effective separation of electrons and holes, aggravate the recombination of electrons and holes, and achieve the diffusion distance Long, long carrier diffusion distance, good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

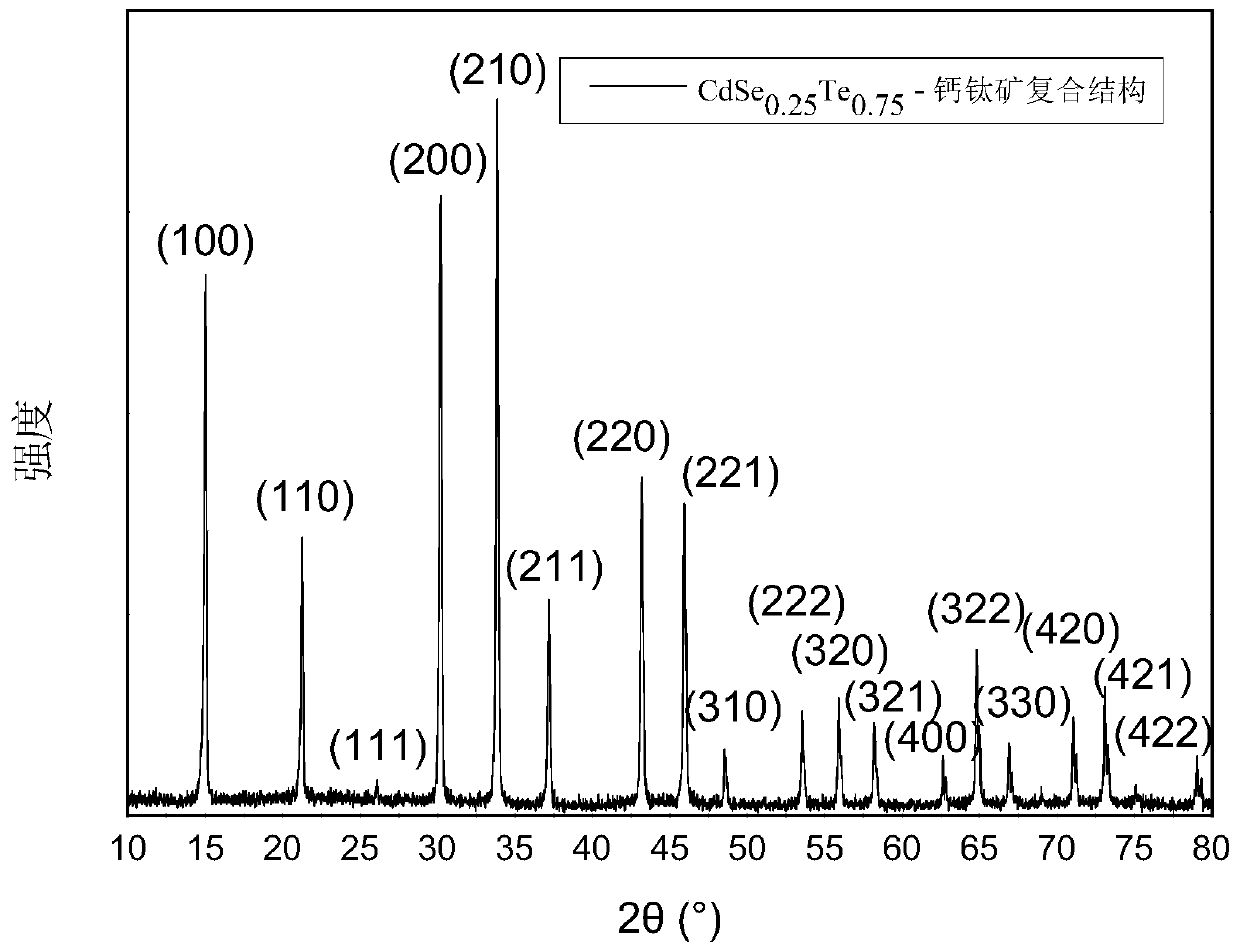

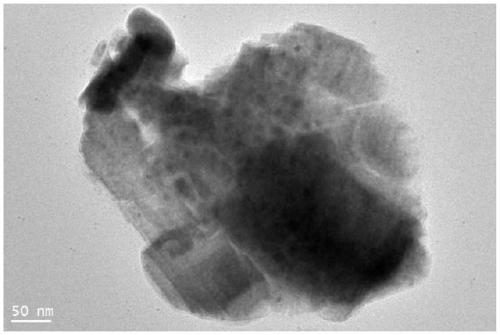

[0043] (1) Preparation of CdSeTe quantum dots by aqueous phase method: sodium borohydride, selenium powder, tellurium powder, Cd(NO 3 ) 2 As a raw material, thioglycolic acid was used as a stabilizer to prepare a CdSeTe quantum dot colloidal solution in a nitrogen atmosphere, and the same volume of acetone was added to the clear and transparent solution obtained by the reaction, and centrifuged to obtain a CdSeTe powder sample, which was composed of CdSeTe 0.25 Te 0.75 ;

[0044] (2) Take 367mg PbBr 2 Dissolve in 5mL toluene, dissolve at 80°C for 30min, make it fully dissolved, and obtain solution Ⅰ;

[0045] (3) Dissolve 56mg of methylammonium bromide (CAS No. 6876-37-5) into 1mL of DMF (N,N-dimethylformamide), and stir until it is completely dissolved to obtain solution II;

[0046] (4) Take 210mg of CdSeTe (0.92mmol) quantum dot powder, add it to the solution II of step (3), and add 0.1mL (0.315mmol) oleic acid and 0.05mL (0.15mmol) oleylamine, and ultrasonically react ...

Embodiment 2

[0059] (1) Preparation of CdSe quantum dots by aqueous phase method: sodium borohydride, selenium powder, Cd(NO 3 ) 2 As a raw material, using thioglycolic acid as a stabilizer, in a nitrogen atmosphere, prepare a CdSe quantum dot colloidal solution, add the same volume of acetone to the clear and transparent solution obtained by the reaction, and centrifuge to obtain a CdSe powder sample;

[0060] (2) 367mg PbBr 2 Dissolve in 5mL toluene, dissolve at 80°C for 30min, make it fully dissolved, and obtain solution Ⅰ;

[0061] (3) Dissolve 56mg of methylammonium bromide in 1mL of DMF (N,N-dimethylformamide), and stir until it is completely dissolved to obtain solution II;

[0062] (4) Take 191 mg of CdSe quantum dot powder, add it to the solution II of step (3), and add 0.1 mL oleic acid and 0.05 mL oleylamine, and ultrasonically react for 30 minutes to obtain a mixed solution;

[0063] (5) Add the mixed solution into solution I, the volume ratio of the two is 1:5, and stir mag...

Embodiment 3

[0066] (1) Preparation of CdTe quantum dots by aqueous phase method: sodium borohydride, tellurium powder, Cd(NO 3 ) 2 As a raw material, using thioglycolic acid as a stabilizer, in a nitrogen atmosphere, prepare a CdTe quantum dot colloidal solution, add the same volume of acetone to the clear and transparent solution obtained by the reaction, and centrifuge to obtain a CdTe powder sample;

[0067] (2) 367mg PbBr 2 Dissolve in 5mL toluene, dissolve at 80°C for 30min, make it fully dissolved, and obtain solution Ⅰ;

[0068] (3) Dissolve 56mg of methylammonium bromide in 1mL of DMF (N,N-dimethylformamide), and stir until it is completely dissolved to obtain solution II;

[0069] (4) Take 230 mg of CdTe quantum dot powder, add it to the solution of step (3), and add 0.1 mL of oleic acid and 0.05 mL of oleylamine, and ultrasonically react for 30 minutes to obtain a mixed solution;

[0070] (5) Add the mixed solution to solution I, the volume ratio of the two is 1:5, and stir m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com