Semiconductor structure and forming method thereof

A technology of semiconductor and gate structure, which is applied in the field of semiconductor structure and its formation, can solve the problems that the electrical performance of semiconductor devices needs to be improved, and achieve the effects of reducing body region leakage current, improving electrical performance, and increasing diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

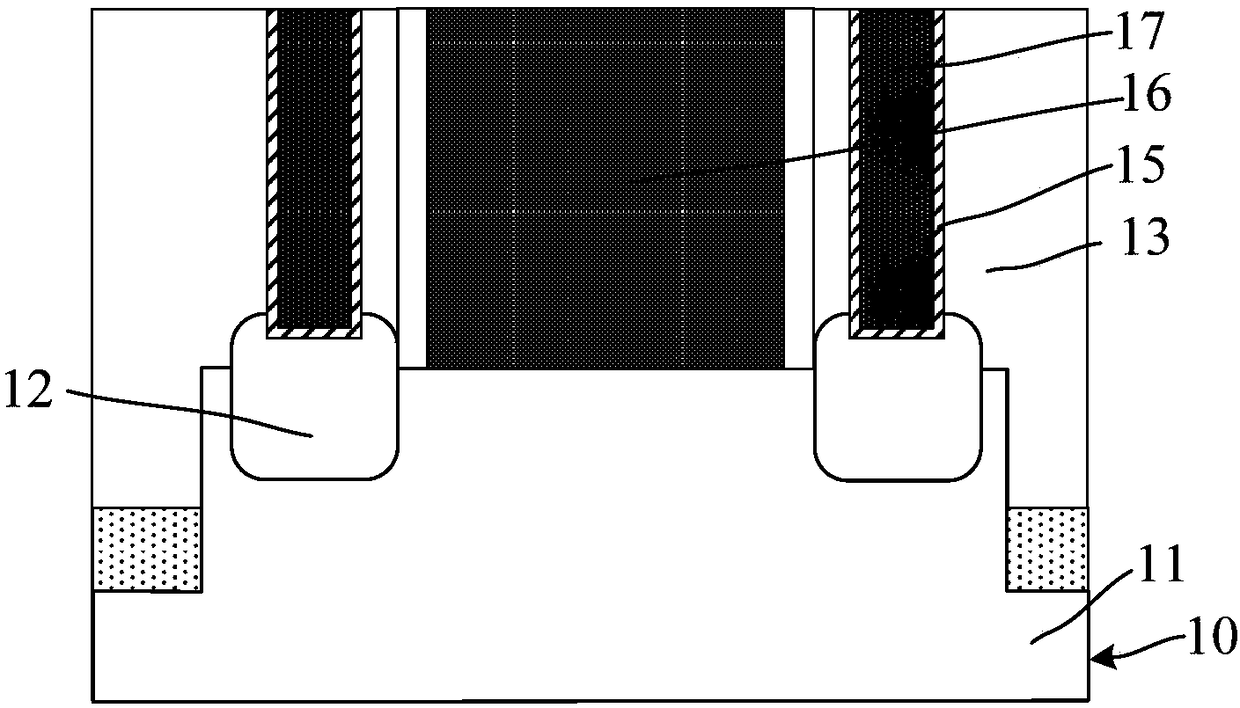

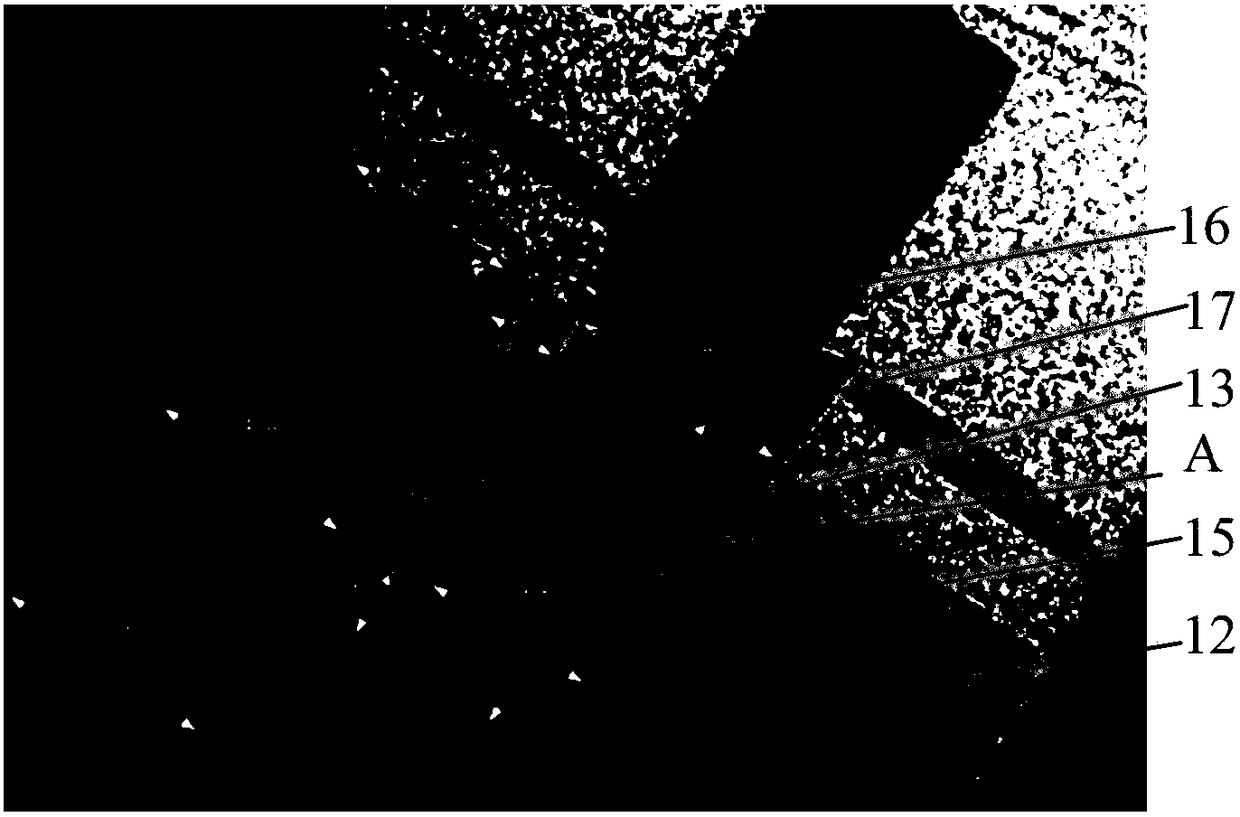

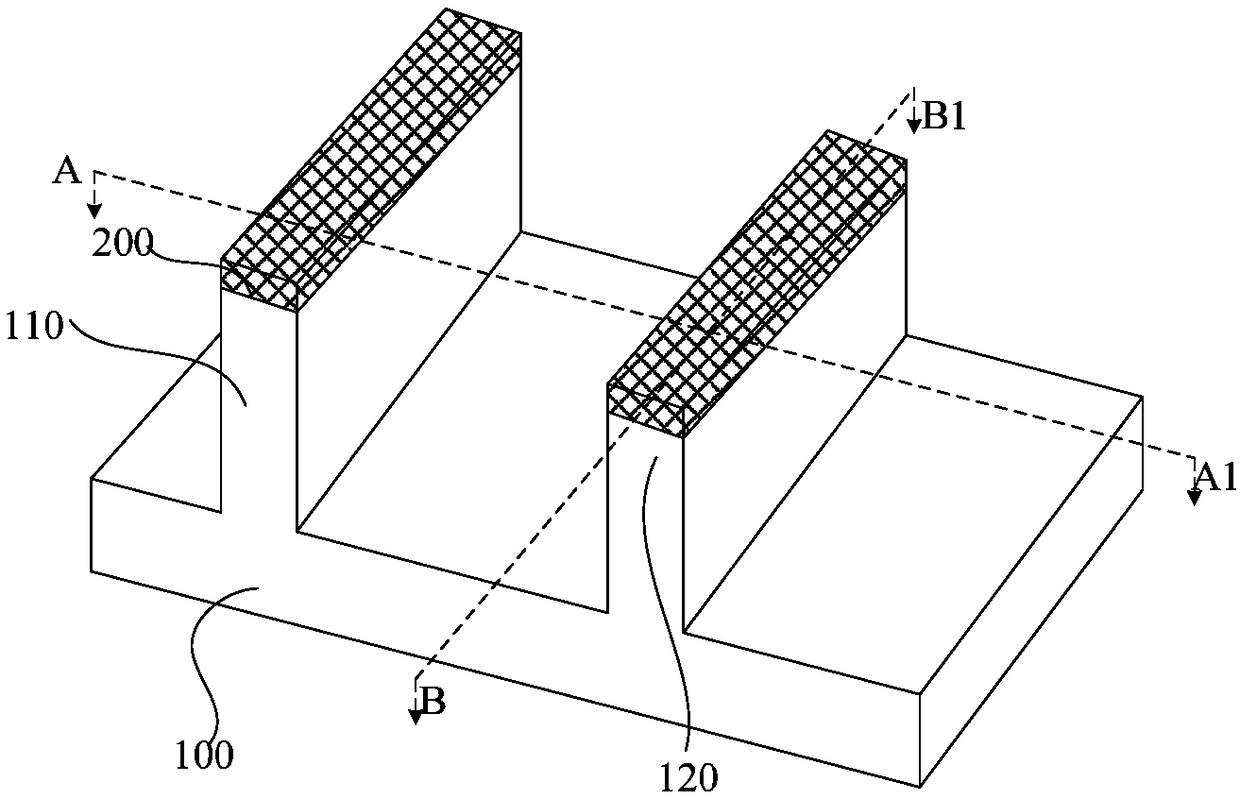

[0016] It can be known from the background art that after adopting the metal silicide layer technology, the electrical performance of the formed semiconductor device still needs to be improved. refer to figure 1 , shows a schematic structural diagram corresponding to a method for forming a semiconductor structure. The reason why the electrical performance of the formed semiconductor device still needs to be improved is analyzed in combination with a method for forming a semiconductor structure.

[0017] The forming method includes: forming a base 10, the base 10 includes a substrate 11, a gate structure 16 on the substrate 11, and source-drain doped epitaxy in the base 10 on both sides of the gate structure 16. layer 12, and a dielectric layer 13 located on the substrate 10 exposed by the gate structure 16; contact openings (not shown) exposing the source-drain doped epitaxial layer 12 are formed on both sides of the gate structure 16, The contact opening includes a through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com