Semiconductor structures and methods of forming them

A technology of semiconductor and gate structure, applied in the field of semiconductor structure and its formation, can solve the problems of semiconductor structure electrical performance and yield decline, reduce body leakage current, improve formation quality and quality uniformity, and improve electrical performance and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

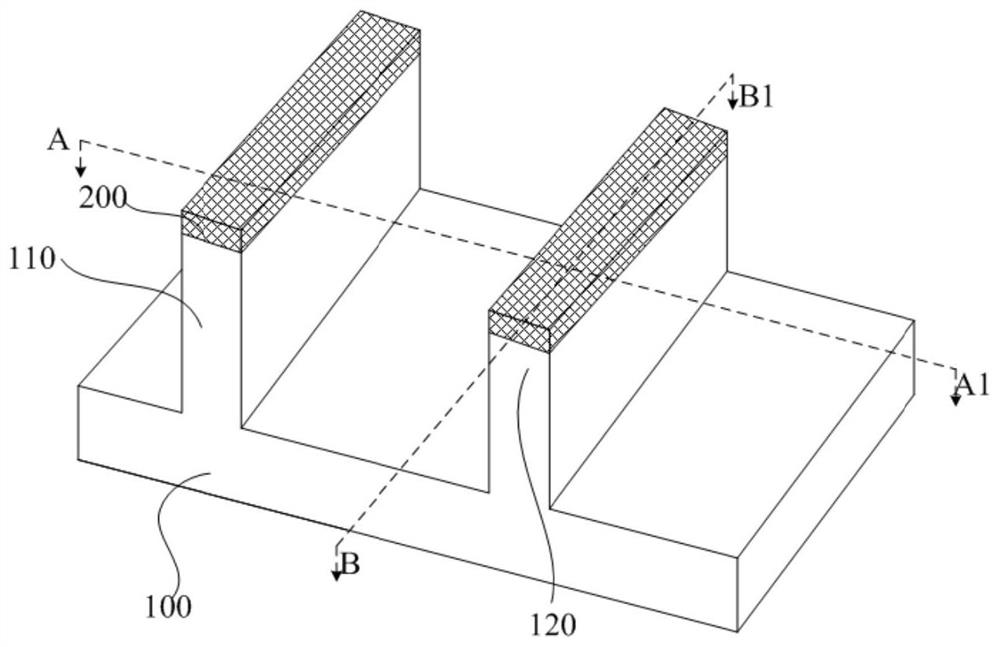

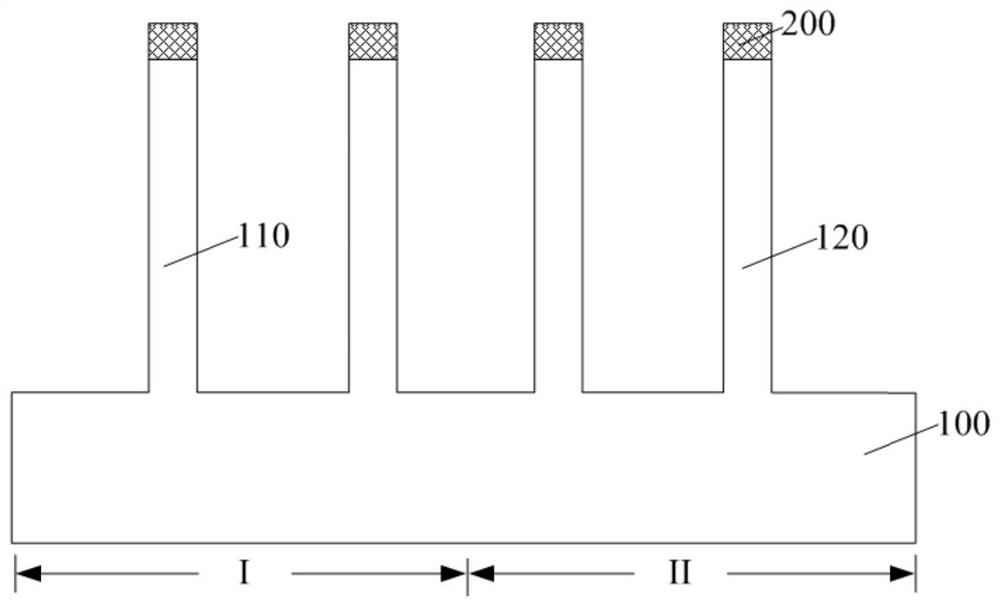

Embodiment Construction

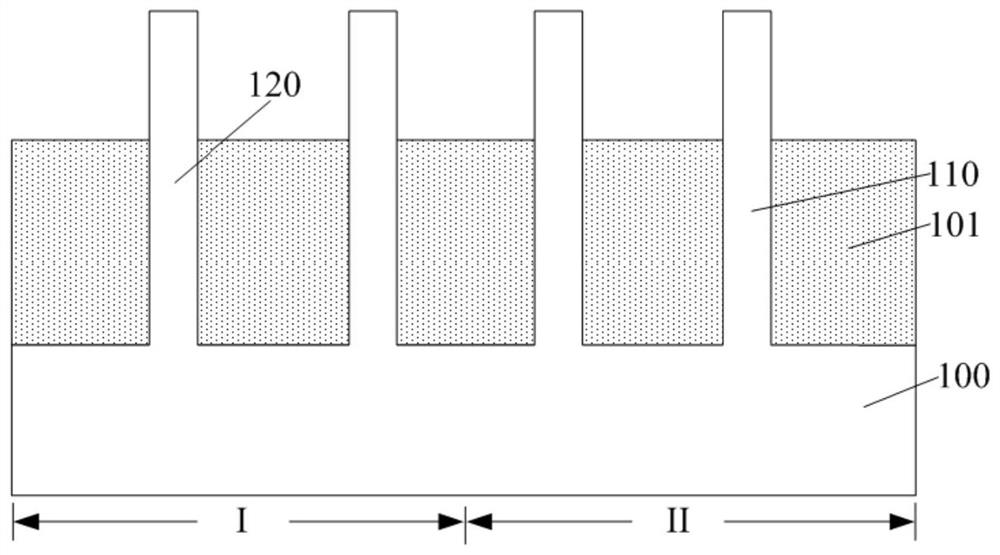

[0014] It can be seen from the background art that the pre-amorphization (Pre-amorphization Implant, PAI) process can effectively reduce the height of the Schottky barrier, but it easily leads to a decrease in the electrical performance and yield of the formed semiconductor structure. Analyze the reasons for this:

[0015] The pre-amorphization process is generally an ion implantation process, and in order to form an amorphous layer, the ion energy and ion dose of the ion implantation process are high, but the higher ion energy and ion dose are likely to cause the end of the range (End OfRange , EOR) defect formation, that is, defects are easily formed at the bottom of the amorphous layer.

[0016] However, in the current semiconductor structure formation process, metal atoms in the metal layer and Si atoms in the source-drain doped epitaxial layer usually diffuse and react with each other to form a metal silicide layer.

[0017] When defects appear at the end of the range (E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com