A kind of preparation method of nano polyhedral copper oxide powder for catalysis

A technology of copper oxide powder and polyhedron, applied in chemical instruments and methods, copper oxide/copper hydroxide, nanotechnology for materials and surface science, etc., can solve problems such as excessive particle size and poor catalytic performance, and achieve synthesis Low temperature, improved performance of catalytic degradation of organic pollutants, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

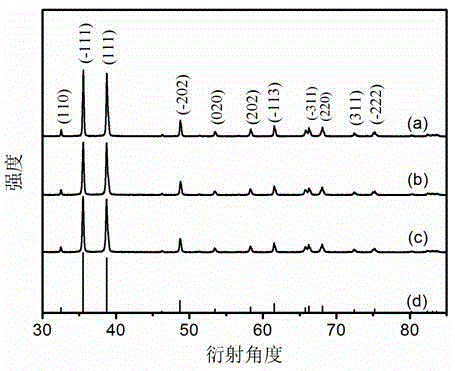

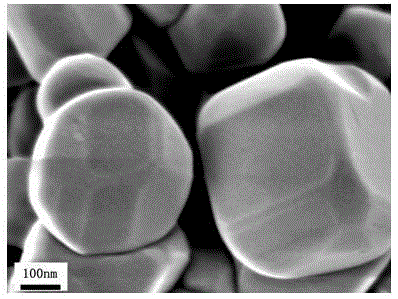

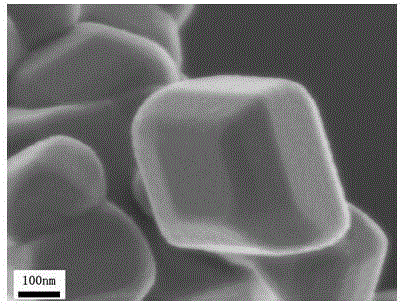

Image

Examples

Embodiment 1

[0035] A preparation method of nano polyhedral copper oxide powder for catalysis, specifically comprising the following steps:

[0036] (1) Dissolve 15.1g of copper salt in 125ml of deionized water to make a copper salt solution with a concentration of 0.5mol / l, then adjust the pH to 6-8 with alkali to obtain a copper salt solution with a pH of 6-8 ;

[0037] The base is NH 3 ·H 2 O;

[0038] The copper salt is Cu(NO 3 ) 2 .3H 2 O;

[0039] (2) Put the copper salt aqueous solution with a pH of 6-8 obtained in step (1) in a constant temperature magnetic stirrer to control the temperature at 60°C and stir at a speed of 450r / min for 1.5h, and suction filter after precipitation is formed. The obtained filter cake is washed with deionized water for 2-3 times, and then dried at a controlled temperature of 60°C to obtain a precursor;

[0040] (3) Put the sodium salt, potassium salt and the precursor obtained in step (2) into the ball mill tank together, and control the balls ...

Embodiment 2

[0049] A preparation method of nano polyhedral copper oxide powder for catalysis, specifically comprising the following steps:

[0050] (1) Dissolve 10.655g of copper salt in 125ml of deionized water to make a copper salt aqueous solution with a concentration of 0.5mol / l, and then adjust the pH to 6-8 with alkali to obtain a copper salt aqueous solution with a pH of 6-8 ;

[0051] The base is NH 3 ·H 2 O, the copper salt is CuCl 2 .2H 2 O;

[0052] (2) Put the copper salt aqueous solution with a pH of 6-8 obtained in step (1) in a constant temperature magnetic stirrer to control the temperature at 60°C and stir at a speed of 450r / min for 1.5h, and suction filter after precipitation is formed. The obtained filter cake is washed with deionized water for 2-3 times, and then dried at a controlled temperature of 60°C to obtain a precursor;

[0053] (3) Put the sodium salt, potassium salt and the precursor obtained in step (2) into the ball mill tank together, and control the ...

Embodiment 3

[0058] A preparation method of nano polyhedral copper oxide powder for catalysis, specifically comprising the following steps:

[0059] (1) Dissolve 15.1g of copper salt in 125ml of deionized water to make a copper salt solution with a concentration of 0.5mol / l, then adjust the pH to 6-8 with alkali to obtain a copper salt solution with a pH of 6-8 ;

[0060] Described alkali is NaOH; Described copper salt is Cu(NO 3 ) 2 .3H 2 O;

[0061] (2) Put the copper salt aqueous solution with a pH of 6-8 obtained in step (1) in a constant temperature magnetic stirrer to control the temperature at 60°C and stir at a speed of 450r / min for 1.5h, and suction filter after precipitation is formed. The obtained filter cake is washed with deionized water for 2-3 times, and then dried at a controlled temperature of 60°C to obtain a precursor;

[0062] (3) Put the sodium salt, potassium salt and the precursor obtained in step (2) into the ball mill tank together, and control the balls in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com