Preparation method of high dispersion barium sulfate composite material for plastic masterbatch

A composite material and plastic masterbatch technology, which is applied in the field of preparation of highly dispersed barium sulfate composite materials, can solve the problems of affecting the processing performance of plastic masterbatch, poor direct application effect, irregular particle shape, etc., and achieves excellent UV resistance Ability, good dispersibility and crystal morphology, effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

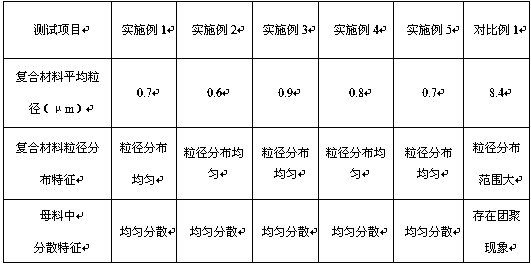

Examples

Embodiment 1

[0032] a. Immerse the barium sulfate in a low-concentration titanium sulfate solution, and filter it out after 25 minutes;

[0033] b. Mix the impregnated barium sulfate with urea solution, add sodium dodecylbenzenesulfonate as a dispersant, stir and disperse for 13 minutes, add high-concentration titanium sulfate solution drop by drop under heating condition, after the reaction is completed, suction filter , the filter residue was washed with deionized water to prepare nano-BaSO 4 / TiO 2 Composite powder;

[0034] c, the nanometer BaSO that step b obtains 4 / TiO 2 Stir the composite powder and impurity-free water evenly in a ball mill, further add carboxypolybutadiene, and ball mill to obtain a slurry;

[0035] d. Press filter and dry the slurry obtained in step c to obtain carboxypolybutadiene-coated BaSO 4 / TiO 2 of composite materials.

[0036] In step a, the mass concentration of the low-concentration titanium sulfate solution is 25%; in step b, the mass concentrat...

Embodiment 2

[0040] a. Immerse the barium sulfate in a low-concentration titanium sulfate solution, and filter it out after 22 minutes;

[0041] b. Mix the impregnated barium sulfate with urea solution, add sodium dodecylbenzenesulfonate as a dispersant, stir and disperse for 11 minutes, add high-concentration titanium sulfate solution drop by drop under heating conditions, after the reaction is completed, suction filter , the filter residue was washed with deionized water to prepare nano-BaSO 4 / TiO 2 Composite powder;

[0042] c, the nanometer BaSO that step b obtains 4 / TiO 2 Stir the composite powder and impurity-free water evenly in a ball mill, further add carboxypolybutadiene, and ball mill to obtain a slurry;

[0043] d. Press filter and dry the slurry obtained in step c to obtain carboxypolybutadiene-coated BaSO 4 / TiO 2 of composite materials.

[0044] In step a, the mass concentration of the titanium sulfate solution of low concentration is 22%; In step b, the mass concen...

Embodiment 3

[0048] a. Immerse the barium sulfate in a low-concentration titanium sulfate solution, and filter it out after 28 minutes;

[0049] b. Mix the impregnated barium sulfate with urea solution, add sodium dodecylbenzenesulfonate as a dispersant, stir and disperse for 14 minutes, add high-concentration titanium sulfate solution drop by drop under heating conditions, after the reaction is completed, suction filter , the filter residue was washed with deionized water to prepare nano-BaSO 4 / TiO 2 Composite powder;

[0050] c, the nanometer BaSO that step b obtains 4 / TiO 2 Stir the composite powder and impurity-free water evenly in a ball mill, further add carboxypolybutadiene, and ball mill to obtain a slurry;

[0051] d. Press filter and dry the slurry obtained in step c to obtain carboxypolybutadiene-coated BaSO 4 / TiO 2 of composite materials.

[0052] In step a, the mass concentration of the titanium sulfate solution of low concentration is 27%; In step b, the mass concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com