Preparation method of M-site doped vanadium MXene

A vanadium-based, powder-based technology, applied in the field of preparation of two-dimensional layered materials, can solve the problems of limited material performance control, V-layer doping, simultaneous doping, etc., to achieve improved liquid phase stripping ability, process controllable, promote the lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of M-site doped vanadium-based MXene, comprising the following steps:

[0023] Step 1: Mix metal powder, aluminum powder, carbon powder and molten salt in a certain proportion to make powder. The mixing ratio of metal powder, aluminum powder, carbon powder and mixed molten salt is the molar ratio (2-2.3): (1.05~1.2): (1~1.1): (5~25), wherein the metal powder is a three-mixed powder formed by V powder and any two of Ti, Cr, Mo, Zr, and Nb powders, and V powder is required to be in The molar proportion of the three-phase mixed powder is greater than 50%. The mixed molten salt is a mixture of sodium chloride and potassium chloride in any proportion, and it needs to be mixed and recrystallized before use, that is, the weighed mixed molten salt is dissolved in A small amount of water, then heat and evaporate the water to obtain crystalline salt, and finally grind and refine to obtain the final usable mixed molten salt. The carbon powder is any one of gra...

Embodiment 1

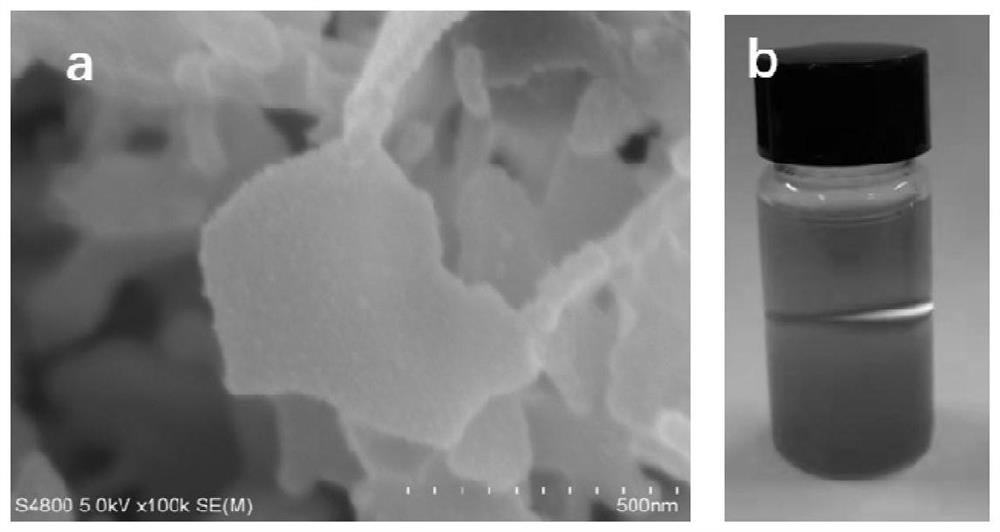

[0027] Metal powder (containing 80% V powder, 5% Ti powder and 15% Cr powder), aluminum powder, graphite powder and molten salt (sodium chloride: potassium chloride = 2:1) according to 2:1.05:1.1:5 Mix the ratio of powder 1 to make powder 1; then put powder 1 in a mortar, add 10ml of deionized water and grind it under air condition for 5 minutes to make it preliminarily mix, and then transfer it to a ball mill tank for ball milling for 6 hours to get powder 2 , and then put the powder 2 in a magnetic boat and sinter at 960°C for 3 hours under the atmosphere (95% argon, 5% carbon dioxide) to obtain the M-site doped MAX phase, which is recorded as MAX phase powder 1; take 5g of the MAX phase Powder 1 was added to 30ml of lithium fluoride hydrochloride solution, followed by magnetic stirring at 30°C for 12 hours. After completion, it was cleaned, centrifuged, and dried to obtain the M-site solid-solution doped MXene material. We doped the synthesized M-site Ti and Cr dual element...

Embodiment 2

[0029] Metal powder (containing 90% V powder, 5% Zr powder and 5% Ti powder), aluminum powder, conductive carbon black and molten salt (sodium chloride: potassium chloride = 1:1) according to 2.3:1.2:1.05: The ratio of 25 was mixed to make powder 1; then powder 1 was placed in a mortar, 18ml of ethanol was added, and it was ground for 8 minutes under air conditions for preliminary mixing, and then transferred to a ball mill jar for ball milling for 3 hours to obtain powder 2. Finally, put the powder 2 in a magnetic boat and sinter at a high temperature of 1430°C for 4 hours under the atmosphere (argon 95%, hydrogen 5%) to obtain the M-site doped MAX phase, which is designated as MAX phase powder 1; take 8g of MAX phase powder Body 1 was added to 32ml of hydrofluoric acid solution, followed by magnetic stirring at 20°C for 24 hours, after completion, it was cleaned, centrifuged, and dried to obtain the M-site solid-solution doped MXene material. The XRD analysis of the synthesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com