Method for regulating crystal growth of perovskite layer and application of perovskite layer in solar cell

A solar cell and crystal growth technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as the limited effect of perovskite, and achieve the effects of promoting the commercialization process, improving efficiency, and high coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for regulating the growth of perovskite layer crystals, preparing a 2,2'-bipyridyl layer on the surface of the anode interface layer NiOx, and then preparing a perovskite layer (FAPbI 3 ) 0.85 (MAPbI 3 ) 0.15 . Concrete preparation process is as follows:

[0038] Firstly, the quartz glass sheet was cleaned by ultrasonic cleaning with deionized water, acetone, detergent, deionized water and isopropanol in sequence, each step was 20 min each. After drying in an oven, it was treated with PLASMA (oxygen plasma) for 4 minutes. Then, spin-coat a layer of NiOx thin film on the above-mentioned treated quartz glass sheet with a thickness of about 40nm. The ethanol solution of 2,2'-bipyridyl was spin-coated on the NiOx layer in a nitrogen atmosphere glove box at a concentration of 1 mg mL –1 , the rotation speed is 3000rpm, and annealed at 100°C for 10h. Subsequently, the (FAPbI 3) 0.85 (MAPbI 3 ) 0.15 The solution was spin-coated on the 2,2'-bipyridine layer,...

Embodiment 2

[0040] A method for regulating the growth of perovskite layer crystals, preparing a 4,4'-bipyridyl layer on the surface of the anode interface layer NiOx, and then preparing a perovskite layer (FAPbI 3 ) 0.85 (MAPbI 3 ) 0.15 . The specific preparation process is the same as in Example 1.

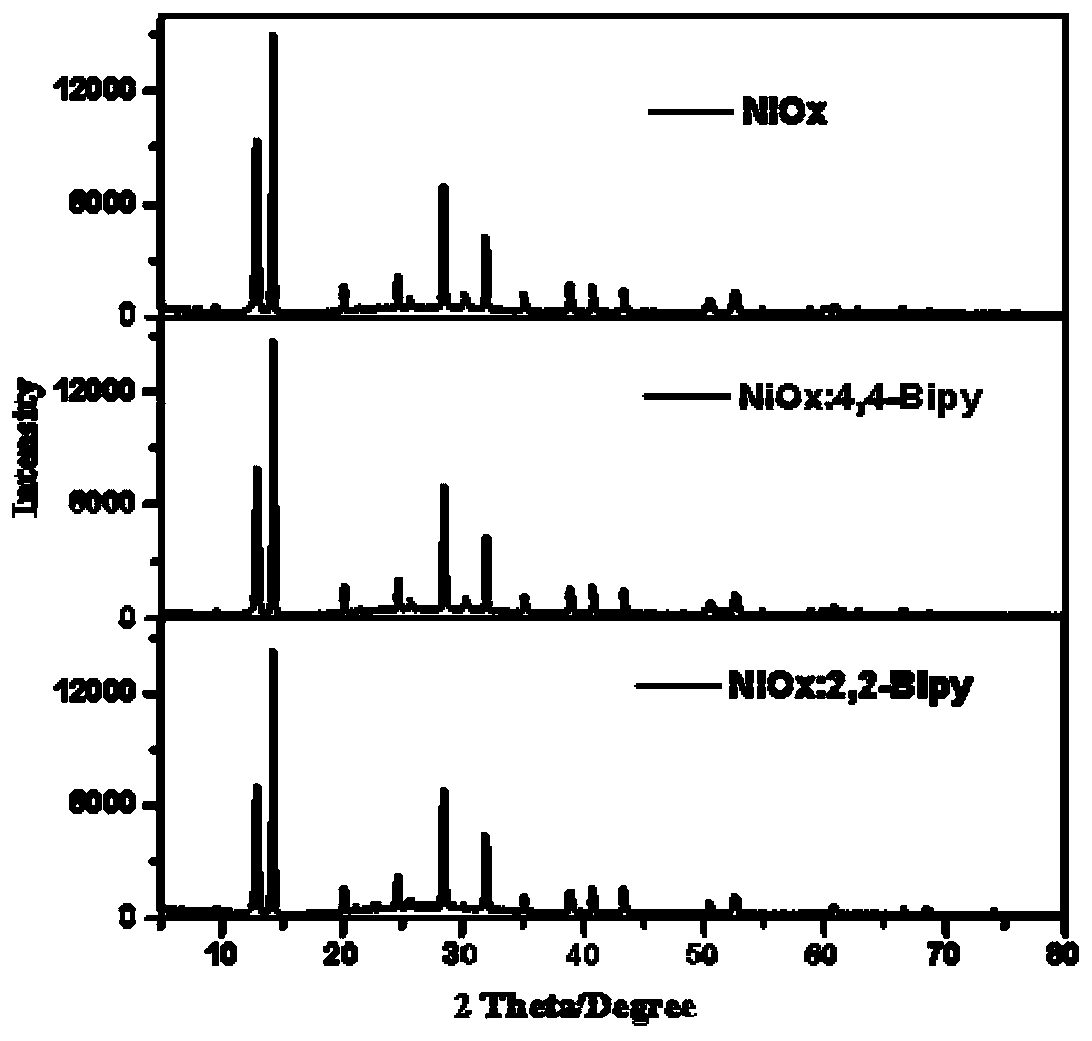

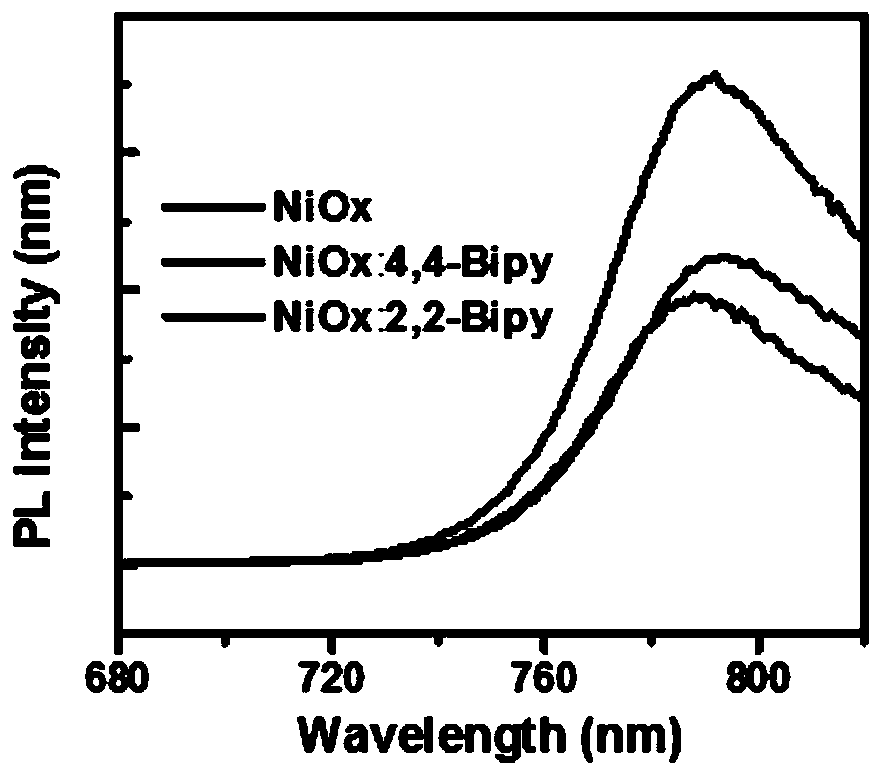

[0041] The perovskite layer prepared by embodiment 1 and implementation 2 is compared with the unmodified perovskite layer, and its SEM figure and particle size distribution figure are as follows figure 1 As shown, the nucleation rate and crystal growth of the crystal can be reflected by observing the morphology and particle size distribution of the modified perovskite crystal. The faster the nucleation, the smaller the particle size of the crystal, from figure 1 It can be seen that after a layer of 2,2'-bipyridine or 4,4'-bipyridine was modified on the surface of NiOx, the particle size of the perovskite crystal was smaller than that of the unmodified one, indicating that the introducti...

Embodiment 3

[0044] A method for regulating the growth of perovskite layer crystals, preparing a 1,10-phenanthroline layer on the surface of the anode interface layer NiOx, and then preparing a perovskite layer (FAPbI 3 ) 0.85 (MAPbI 3 ) 0.15 . The specific preparation process is the same as in Example 1. The results show that after the NiOx surface is modified with a layer of 1,10-phenanthroline, the fluorescence intensity of the perovskite film is stronger than that of the unmodified perovskite film on the NiOx layer. It can be seen that the NiOx surface is modified with a layer of 1,10-phenanthroline The morphology of the perovskite film is significantly better than that of the unmodified perovskite film with the NiOx layer, indicating that the introduction of the 1,10-phenanthroline layer can regulate the film-forming properties of the perovskite, making the crystal morphology of the perovskite better .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com