Technological method for preparing high purity nanometer grade powder

A process method and nano-level technology, applied in the field of powder metallurgy process, can solve the problems of long process, difficult to ensure consistent raw materials, and high raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

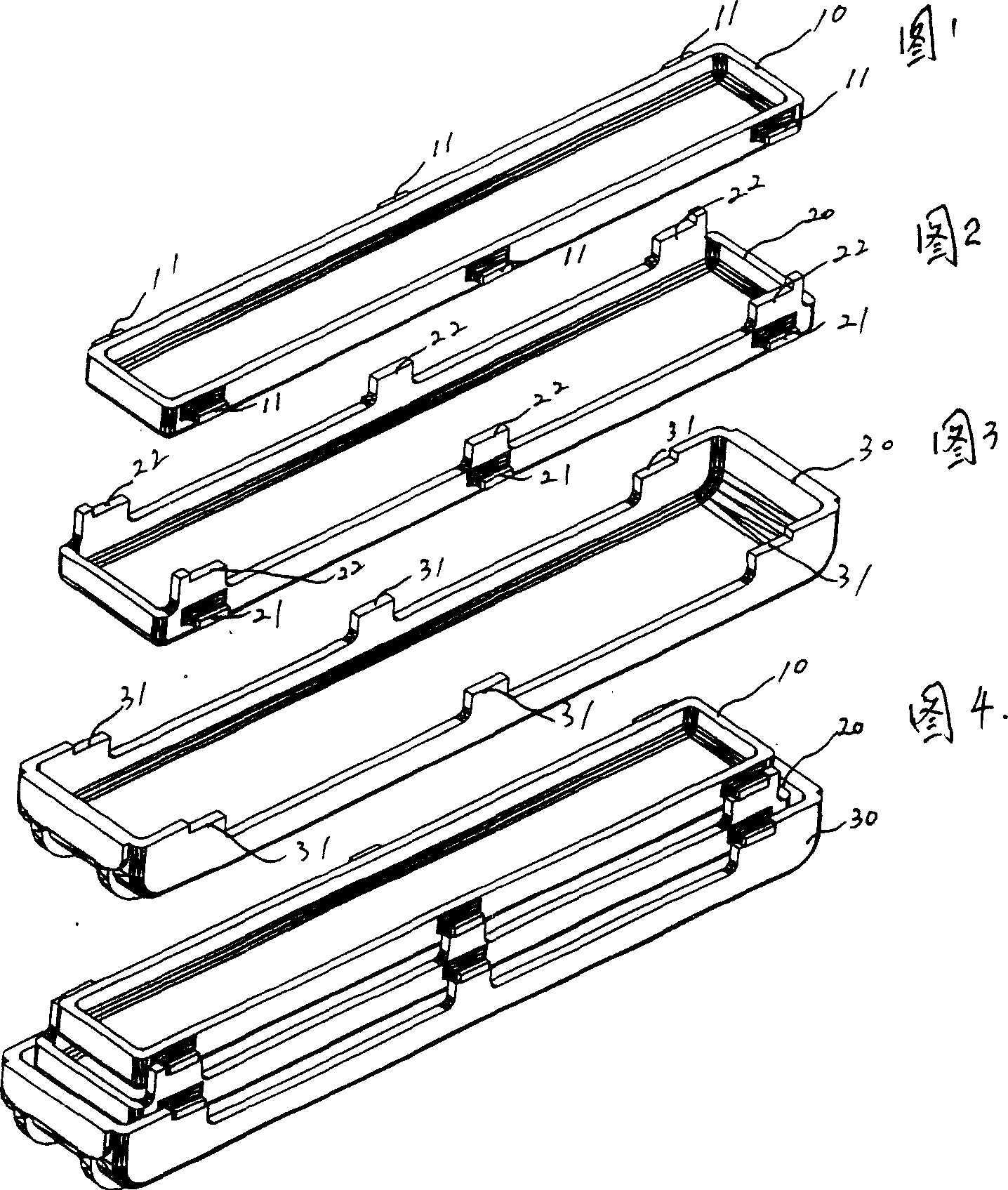

[0009] In the figure, the boat structure: 6 support points 11 are set on the middle and upper parts of both sides of the upper boat 10; 6 support points 21 are also set on the middle and upper parts of the two sides of the middle boat 20 corresponding to the support points of the upper boat, corresponding to the support points. 6 positioning support points 22 are set on the frame surface of the boat (for supporting and limiting and fixing the upper boat); on the frame surface of the lower boat 30, corresponding to the position of the support point of the middle boat, 6 support points 31 are set (for supporting and limit the middle boat), and the bottom is provided with two arc-shaped sliding ribs parallel to the sides (used for the load-bearing of the whole boat and the work sliding in the multi-tube furnace); the whole boat is made of Cr30Ni10 main material + additives, high temperature precision It is cast; the weight distribution of the three-layer boat is - upper layer: mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com