Positive electrode material and preparation method and application thereof

A technology of positive electrode material and matrix material, applied in the field of positive electrode material and its preparation, can solve the problems of environmental pollution, high raw material requirements, high price of cobalt metal, etc., and achieve the effects of reducing manufacturing cost, uniform chemical composition, and shortening synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a positive electrode material, the chemical formula of the positive electrode material is Li 1.2 MnO 2 , the positive electrode material is spherical particles with a median diameter of 7 μm.

[0051] The preparation method of the positive electrode material is as follows:

[0052] (1) Mix sodium carbonate, manganese carbonate and lithium carbonate at a molar ratio of Li:Na:Mn of 0.25:1:0.75, and perform primary sintering at 700°C under an air atmosphere with a flow rate of 8L / min. 10h, the matrix material NaLi was obtained 0.25 mn 0.75 o 2 ;

[0053] (2) Mix the base material described in step (1) with the second lithium salt at a molar ratio of Li:Mn in the system of 1.2:1, perform secondary sintering at 600°C for 6 hours, wash with water, filter, and dry , to obtain the positive electrode material.

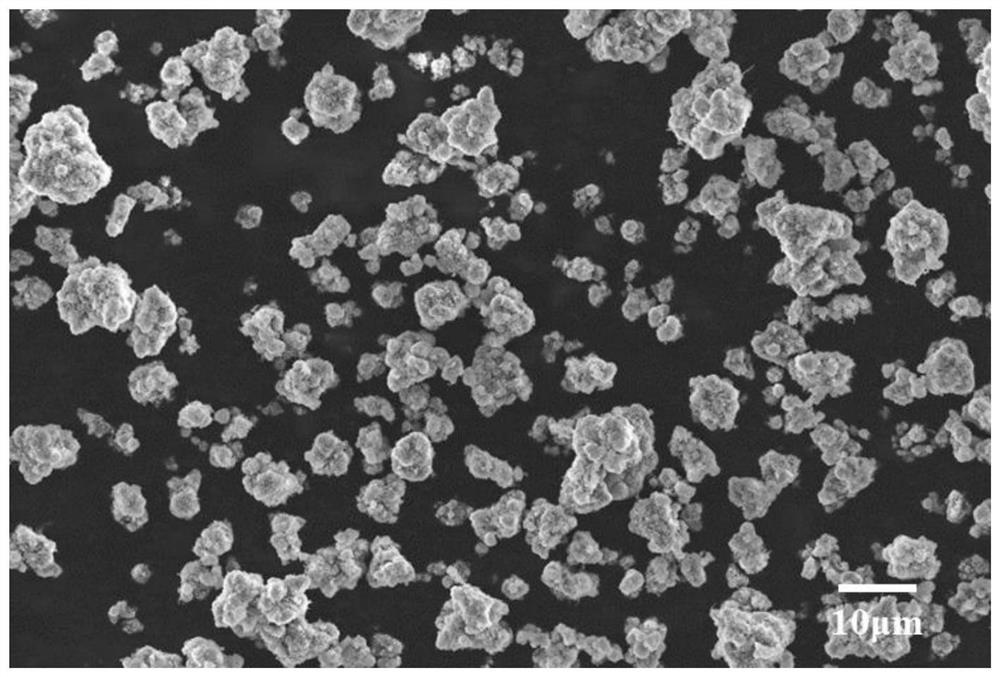

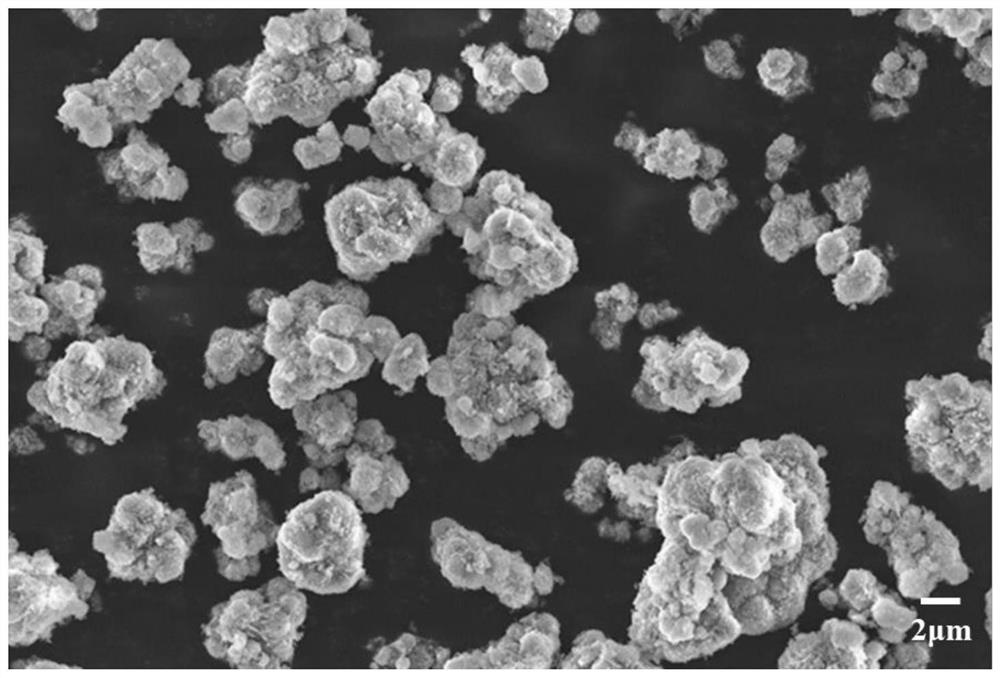

[0054] from figure 1 with figure 2 It can be seen that the positive electrode material provided in Example 1 is agglomerated spherical...

Embodiment 2

[0057] This embodiment provides a positive electrode material, the chemical formula of the positive electrode material is Li 1.1 MnO 2 , the positive electrode material is spherical particles with a median diameter of 1 μm.

[0058] The preparation method of the positive electrode material is as follows:

[0059] (1) Mix sodium chloride, manganese acetate and lithium chloride at a molar ratio of Li:Na:Mn of 0.25:0.8:0.75, and conduct at 500°C under an air atmosphere with a flow rate of 5L / min. Once sintered for 12 hours, the matrix material Na 0.8 Li 0.25 mn 0.75 o 2 ;

[0060] (2) Mix the base material in step (1) with the second lithium salt at a molar ratio of Li:Mn in the system of 1.1:1, perform secondary sintering at 400°C for 8 hours, wash with water, filter, and dry , to obtain the positive electrode material.

Embodiment 3

[0062] This embodiment provides a positive electrode material, the chemical formula of the positive electrode material is Li 1.5 MnO 2 , the positive electrode material is spherical particles with a median diameter of 15 μm.

[0063] The preparation method of the positive electrode material is as follows:

[0064] (1) Mix sodium acetate, manganese carbonate and lithium fluoride at a molar ratio of Li:Na:Mn of 0.25:1:0.75, and conduct the process once at 800°C under an air atmosphere with a flow rate of 10L / min. Sintering for 8h to obtain the matrix material NaLi 0.25 mn 0.75 o 2 ;

[0065] (2) Mix the base material described in step (1) with the second lithium salt at a molar ratio of Li:Mn in the system of 1.5:1, perform secondary sintering at 800°C for 4 hours, wash with water, filter, and dry , to obtain the positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com