High-temperature-resistant and high-humidity-resistant fluoride red fluorescent powder and preparation method thereof

A technology of red light phosphor and fluoride, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low quantum efficiency, thermal quenching, poor high temperature and high humidity resistance, etc., achieve high internal quantum efficiency, promote Good effect of crystal growth and high temperature and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of powder: add the oxide of M to 20-60wt% hydrofluoric acid solution, after all the solids are dissolved, continue to add KF and AF to the above solution 2 , KMnO 4 and K 2 MF 6 Substrate, dropwise add 20-40wt% hydrogen peroxide solution to the solution, stop the dropwise addition after the solution changes color, the whole process is carried out under stirring at 100-1000r / min, after stopping the dropwise addition of the hydrogen peroxide solution, put The reactant is dried at 0-200°C for 0-72 hours, and after drying, the filter cake is taken out, ground and broken through a 100-mesh sieve to obtain K m A n m 1-x f 6 :xMn 4+ solid product.

[0036] Coating of powder: according to the ratio of potassium silicate: hydroxymethylcellulose sodium aqueous solution (CMC-Na): polyethylene glycol aqueous solution (PEG) = 1g: 10 ~ 20mL: 5 ~ 30mL, the mass fraction is respectively measured as 1-5% CMC-Na, 2-10% PEG mass fraction, and stirring at room temperatu...

Embodiment 1

[0038] Example 1: K 1.8 Cu 0.1 Si 0.95 f 6 : 0.05Mn 4+ Phosphor powder preparation.

[0039] 10gSiO 2 Add it to 100mL 40wt% hydrofluoric acid solution, place the polytetrafluoroethylene beaker in a 25°C water bath, after all the solids are dissolved, continue to add 1.8g KF, 2g CuF 2 , 14gKMnO 4 and 10g K 2 SiF 6 , dropwise add 30% hydrogen peroxide solution in the solution, stop dripping after the solution turns golden yellow, the whole process is carried out under stirring at 100r / min, after stopping the dropwise addition of hydrogen peroxide solution, put the reactant in After standing at 25°C for 2 hours, filter the resulting precipitate, wash it with ethanol three times, put the filter cake in a vacuum drying oven, and dry it at 70°C for 1 hour. After drying, take out the filter cake, grind and crush it through a 100-mesh sieve That is, yellow K 1.8 Cu 0.1 Si 0.95 f 6 : 0.05Mn 4+ Phosphor.

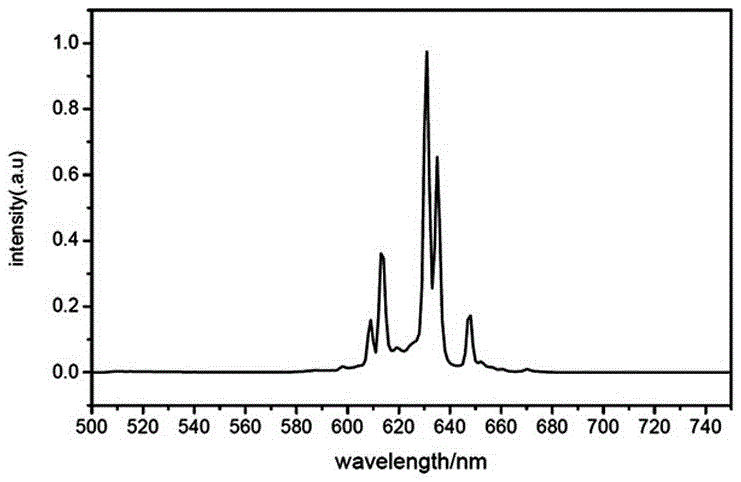

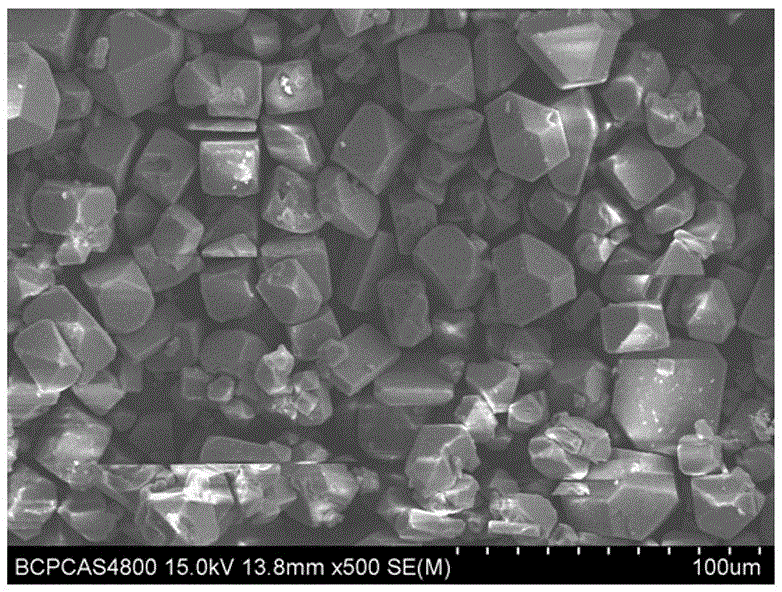

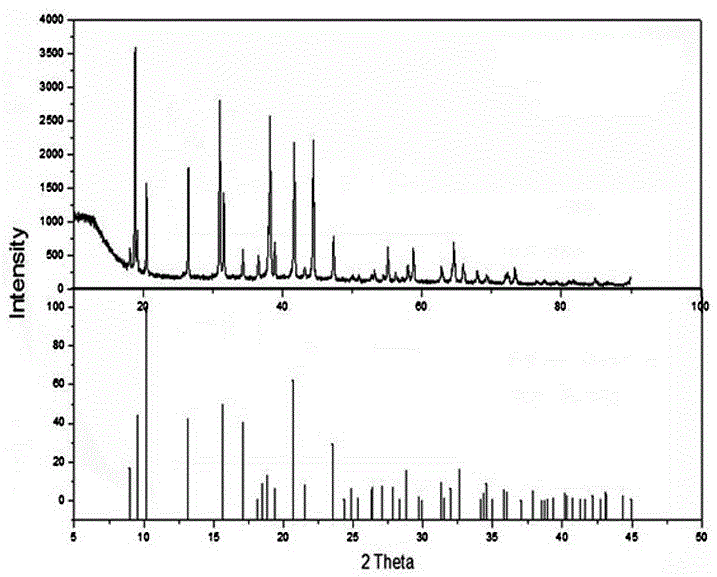

[0040] Observed under a microscope, the obtained fluorescent powde...

Embodiment 2

[0041] Example 2: K 1.8 Cu 0.1 Si 0.95 f 6 : 0.05Mn 4+ Encapsulation of phosphor powder.

[0042] Measure 10mL of CMC-Na with a mass fraction of 1%, and 10mL of 5% PEG, and stir at room temperature to fully swell, add 1g of potassium silicate to the above mixed solution, and stir for 30min to form a mixed sol. Weigh 2g of the fluorescent powder prepared in Example 1 and add it to the above sol, stir at room temperature for 30min, disperse with ultrasonic waves with a frequency of 20KHz, supplemented by stirring at the same time, the stirring rate is 110r / min, stir for 1h, and pump it Filtration, washing with ethanol during the suction filtration, after the suction filtration, place the filter cake in a vacuum drying oven, and vacuum dry at 70°C for 2 hours to obtain a fluoride red phosphor with a core-shell structure.

[0043] The coated phosphor is a kind of yellowish crystal, and the fluffy substance coated on the surface can be seen under the scanning electron microsco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Emission peak | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com