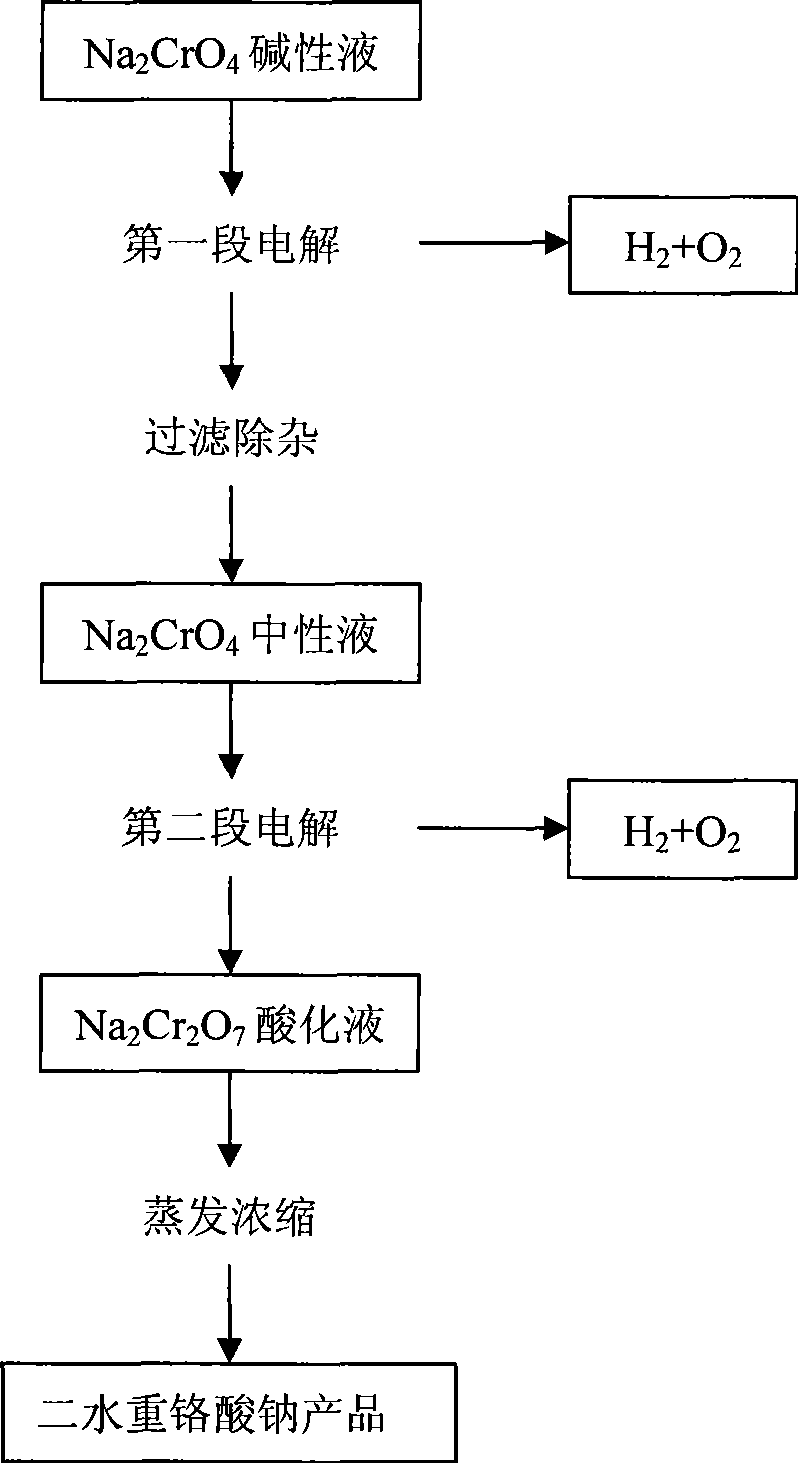

Method for preparing sodium dichromate dehydrate by ionic membrane electrolysis method

A technology of ionic membrane electrolysis and sodium dichromate, applied in the direction of chromate/dichromate, electrolysis process, electrolysis components, etc., can solve problems such as hindering the development of chromate enterprises and adverse to the overall development of the national economy, and achieve crystallization. Good appearance, low cost, and the effect of reducing the amount of distilled water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

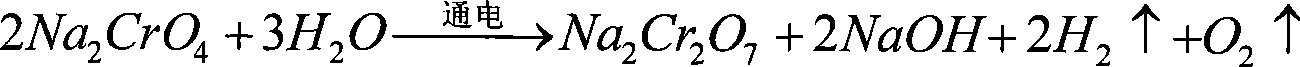

[0031] ①The first stage of electrolysis: In the one-membrane two-chamber electrolyzer device, the sodium chromate alkaline solution with a mass concentration of 20.40% is passed into the anode chamber, and the sodium hydroxide solution with a mass concentration of 18.40% is passed into the cathode chamber. Voltage DC power supply control current 12.00±0.01A (current density 2400A / m 2 ), and electrolyze for 50 minutes at a reaction temperature of 45.0°C. The anode chamber obtains 21.70% (by mass content of sodium dichromate dihydrate) sodium chromate neutral solution, and the cathode chamber obtains 19.86% (by mass content of sodium hydroxide) sodium hydroxide solution. Oxygen produced in the anode chamber and hydrogen produced in the cathode chamber are recovered through gas collecting devices respectively.

[0032] ②The second stage of electrolysis: the anolyte obtained in the first stage of electrolysis is filtered to remove impurities such as aluminum and silicon, and then...

Embodiment 2

[0035] 1. The first stage of electrolysis: the sodium chromate alkaline solution with a mass concentration of 28.41% (in terms of the mass content of sodium dichromate dihydrate) is passed into the anode chamber, and the sodium chromate alkaline solution with a mass concentration of 16.20% (in terms of the mass content of sodium hydroxide) is passed into the anode chamber. The sodium hydroxide solution is passed into the cathode chamber, and the current is controlled by a regulated DC power supply to 6.00±0.01A (current density 1200A / m 2 ), electrolyzed for 139min at a reaction temperature of 60°C. The anode chamber obtains 30.28% (in terms of the mass content of sodium dichromate dihydrate) sodium chromate neutral solution, and the cathode chamber obtains a sodium hydroxide solution with a mass concentration of 18.46% (in terms of the mass content of sodium hydroxide). Oxygen produced in the anode chamber and hydrogen produced in the cathode chamber are recovered through gas ...

Embodiment 3

[0039] ①The first stage of electrolysis: the sodium chromate alkaline solution with a mass concentration of 35.75% (in terms of the mass content of sodium dichromate dihydrate) is passed into the anode chamber, and the mass concentration is 9.04% (in terms of the mass content of sodium hydroxide) The sodium hydroxide solution is passed into the cathode chamber, and the current is controlled by a regulated DC power supply to 15.00±0.01A (the current density is 3000A / m 2 ), electrolyze for 70 minutes at a reaction temperature of 75°C. A sodium chromate neutral solution with a concentration of 37.87% (in terms of the mass content of sodium dichromate dihydrate) is obtained in the anode compartment, and a sodium hydroxide solution with a mass concentration of 12.82% (in terms of the mass content of sodium hydroxide) is obtained in the cathode compartment. Oxygen produced in the anode chamber and hydrogen produced in the cathode chamber are recovered through gas collecting devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com