Titanium nitride powder based on low temperature liquid polymerization process and preparation method of titanium nitride powder

A low-temperature liquid phase method, titanium nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problem that the growth of titanium nitride whiskers is greatly affected by deposition temperature and gas volume, and increase the nitriding Titanium product cost, cumbersome experimental process and other issues, to achieve the effect of rich raw materials, good crystal morphology, and increased diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

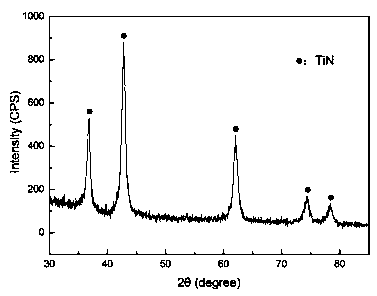

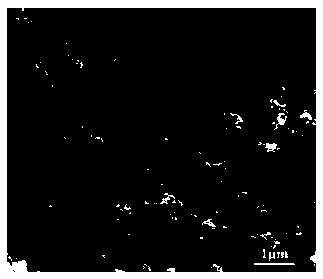

Embodiment 1

[0023] A titanium nitride powder based on a low-temperature liquid phase method and a preparation method thereof. According to the molar ratio of metal magnesium powder: alkali metal inorganic salt: titanium dioxide powder is 1: (1.5 ~ 1.8): (0.25 ~ 0.40), metal magnesium powder, alkali metal inorganic salt and titanium dioxide powder are mixed to obtain mixed powder; The mixed powder is kept in a nitrogen atmosphere at 900-1100°C for 4-6 hours, cooled naturally to obtain a burnt product; then the burnt product is added to hydrochloric acid solution and soaked for 5-6 hours, washed with distilled water for 3-6 hours 5 times, drying at 90-110°C for 8-12 hours to obtain titanium nitride powder based on low temperature liquid phase method.

[0024] The alkali metal inorganic salt described in this embodiment is sodium chloride.

Embodiment 2

[0026] A titanium nitride powder based on a low-temperature liquid phase method and a preparation method thereof. The present embodiment is the same as embodiment 1 except that the alkali metal inorganic salt is magnesium chloride.

Embodiment 3

[0028] A titanium nitride powder based on a low-temperature liquid phase method and a preparation method thereof. The present embodiment is the same as embodiment 1 except that the alkali metal inorganic salt is a mixture of sodium chloride and magnesium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com