Method for preparing multi-stage pore SAPO-34 molecular sieve by mixing tetrahydrofuran with organic amine as template agent

A technology of tetrahydrofuran and organic amine, which is applied in the field of SAPO-34 molecular sieve synthesis, can solve the problems of difficult diffusion of generated products and deactivation of catalysts, and achieves the effects of good crystal morphology and high solid-phase yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of synthesizing the hierarchical porous SAPO-34 molecular sieve with tetrahydrofuran and organic amine mixed template, the steps are as follows:

[0036] Step 1: Weigh 17g of tetraethylammonium hydroxide (TEAOH, 35%) and mix it with 0.74g of tetrahydrofuran, then add it into 17ml of deionized water, and stir evenly to obtain mixed solution A. The molar ratio of tetrahydrofuran to tetraethylammonium hydroxide was 0.25.

[0037] Step 2: Weighing 0.38g of silica sol and 1.36g of pseudo-boehmite were successively dissolved in the mixed solution A obtained in Step 1, and stirred thoroughly for 1 hour until completely dissolved to obtain mixed solution B.

[0038] Step 3: Weigh 4.65g of phosphoric acid solution (mass fraction is 85%) and add it dropwise to the mixed solution B obtained in step 2, and continue to stir for 30min to obtain a milky white mixed gel. The proportioning of the mixed gel is Al2O3:P2O5:SiO2 :(TEAOH+THF):H2O=1:2:0.15:5:160.

[0...

Embodiment 2

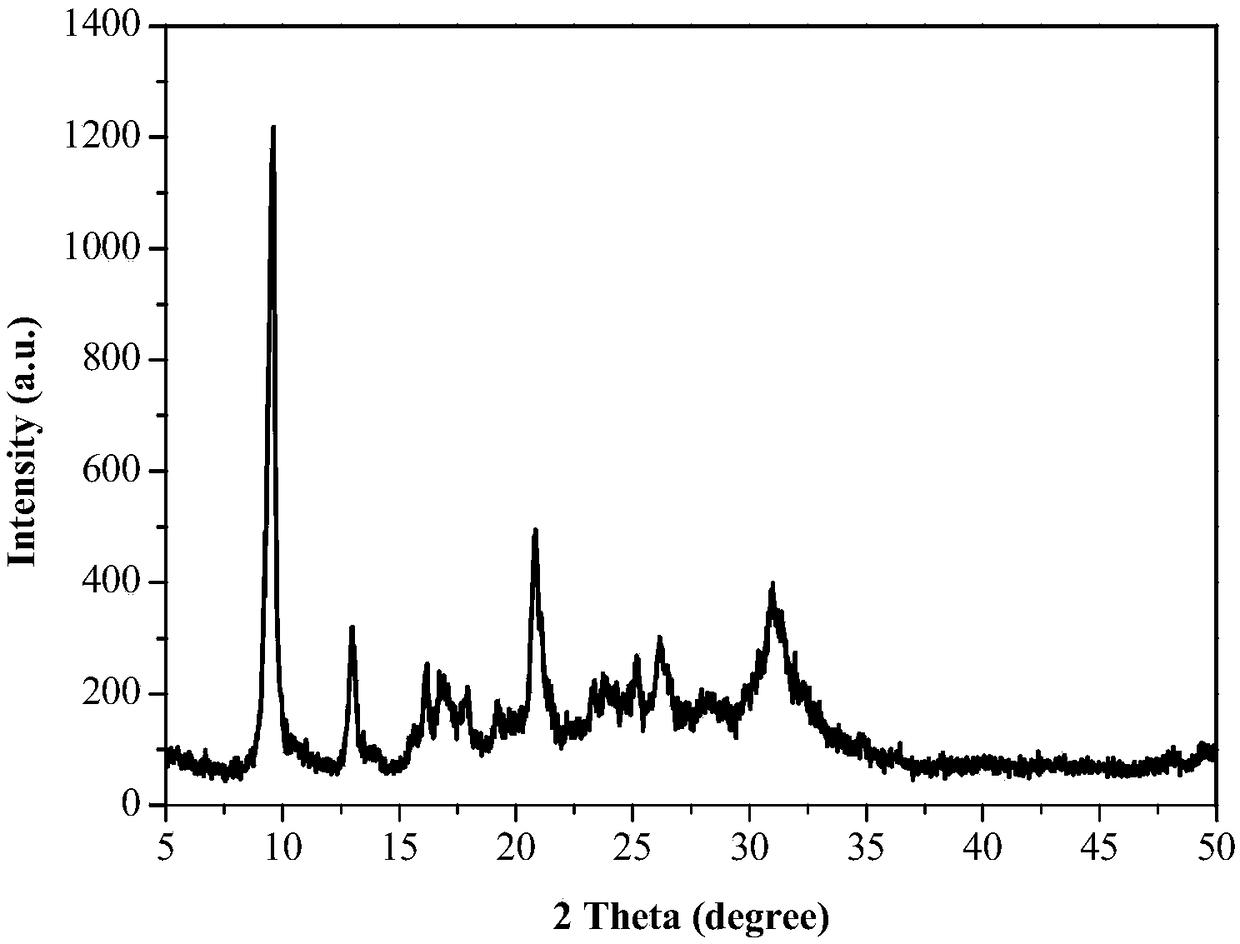

[0041] The preparation method of synthesizing hierarchically porous SAPO-34 molecular sieves with tetrahydrofuran and organic amine mixed templates, the basic steps of its preparation are the same as in Example 1, the difference is: in step one, the mol ratio of tetrahydrofuran and tetraethylammonium hydroxide From 0.25 to 1, such as figure 2 , as shown in 3, the formed SAPO-34 molecular sieve has high crystallinity, no impurity phase exists, and the synthesized sample has a cubic shape. The XRD spectrum is a pure-phase SAPO-34 molecular sieve with a typical CHA skeleton structure.

Embodiment 3

[0043] The preparation method of synthesizing hierarchically porous SAPO-34 molecular sieves with tetrahydrofuran and organic amine mixed templates, the basic steps of its preparation are the same as in Example 1, the difference is: in step one, the mol ratio of tetrahydrofuran and tetraethylammonium hydroxide From 0.25 to 0.1, no SAPO-34 molecular sieves were finally synthesized, and all of them were amorphous gels. Such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com