Profile control agent of injection well

A profile control agent and injection well technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced injection volume and injection ratio of the target layer, high initial viscosity, and small profile control radius, etc. Increased heterogeneity or coefficient of variation, improved shelf life and effectiveness, increased relative permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, prolongation and control experiment of profile control agent gelation time:

[0014] Under indoor static conditions, control the concentration of 0.05-0.4% of the performance regulator to adjust the gelation time, and the corresponding relationship is shown in Table 1 below.

[0015] Components of profile control agents with different gluing time Table 1

[0016] Polyacrylamide Concentration A(%)

[0017] As can be seen from Table 1, the gelling time can reach up to 60 days.

Embodiment 2

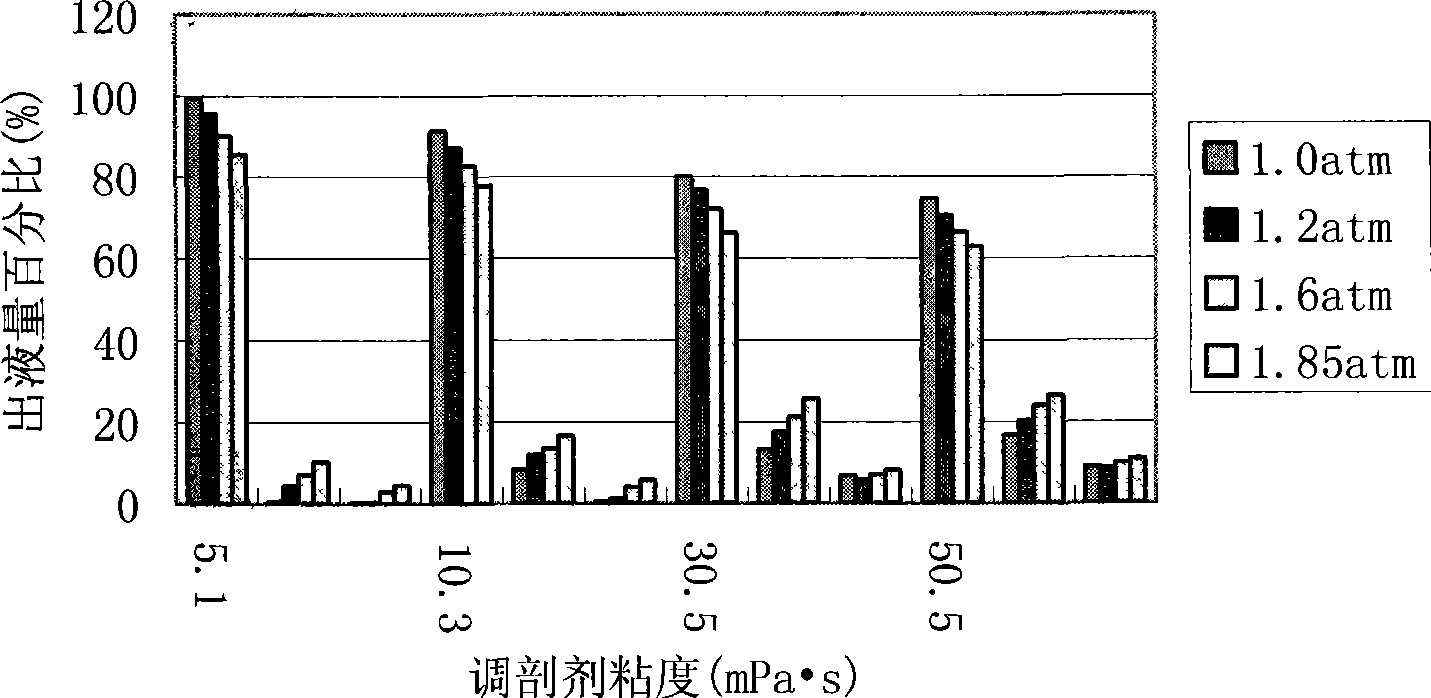

[0018] Example 2. Experiment of profile control agent diversion performance under different viscosity and different injection pressure conditions of the same model:

[0019] Adopt 2052, 514, 106×10 -3 μm 2 The cores were connected in parallel, and the proportion of profile control agent entering the core was measured under different viscosity and different injection pressure conditions. The results are shown in Table 3 and figure 1 . See Table 2 for the preparation of profile control agents with different viscosities

[0020] Preparation of profile control agents with different viscosities Table 2

[0021] profile control agent viscosity

(mPa·s) polyacrylamide

Concentration A(%) polyacrylamide

Subquantity (millions) Chromium salt crosslinking agent dichromic acid

Sodium concentration B(%) performance modifier thiourea

Concentration C (%) 5.1 0.5 150 0.5 0.4 10.3 0.5 180 0.5 0.4 30.5 0.5 420 0.5 0.4 50.5 0.5 600 ...

Embodiment 3

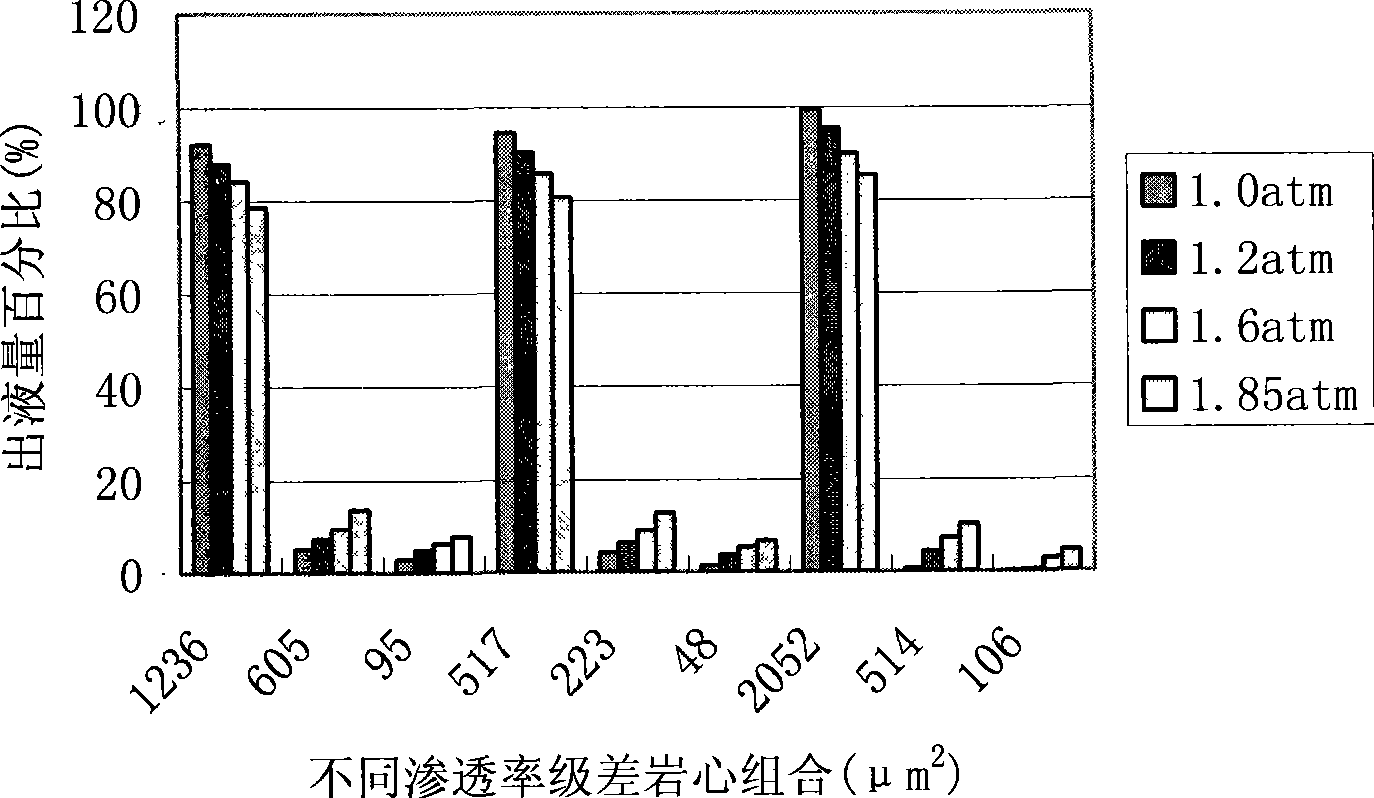

[0025] Example 3. Different model systems with the same viscosity and different injection pressures for profile control agent diversion performance experiment: Three sets of parallel cores were used in the experiment, and the permeability gradients were 2, 2.5, and 4 respectively.

[0026] When the viscosity is 5.1 mPa s, the proportion of profile control agent entering the core under different injection pressures is shown in Table 4

[0027]

[0028] It can be seen from the experimental results that the higher the injection pressure, the greater the viscosity of the profile control agent, and the smaller the proportion of the profile control agent entering the high permeability layer. Therefore, reducing the injection pressure and reducing the viscosity of the profile control agent can effectively increase the proportion of the profile control agent entering the high permeability layer. The larger the permeability difference, the larger the proportion of profile control ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com