Preparation method of chlorine dioxide without production of solids

A technology of chlorine dioxide and solids, applied in the direction of chlorine oxidation, etc., can solve the problems of complex process, environmental pollution, flying loss, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

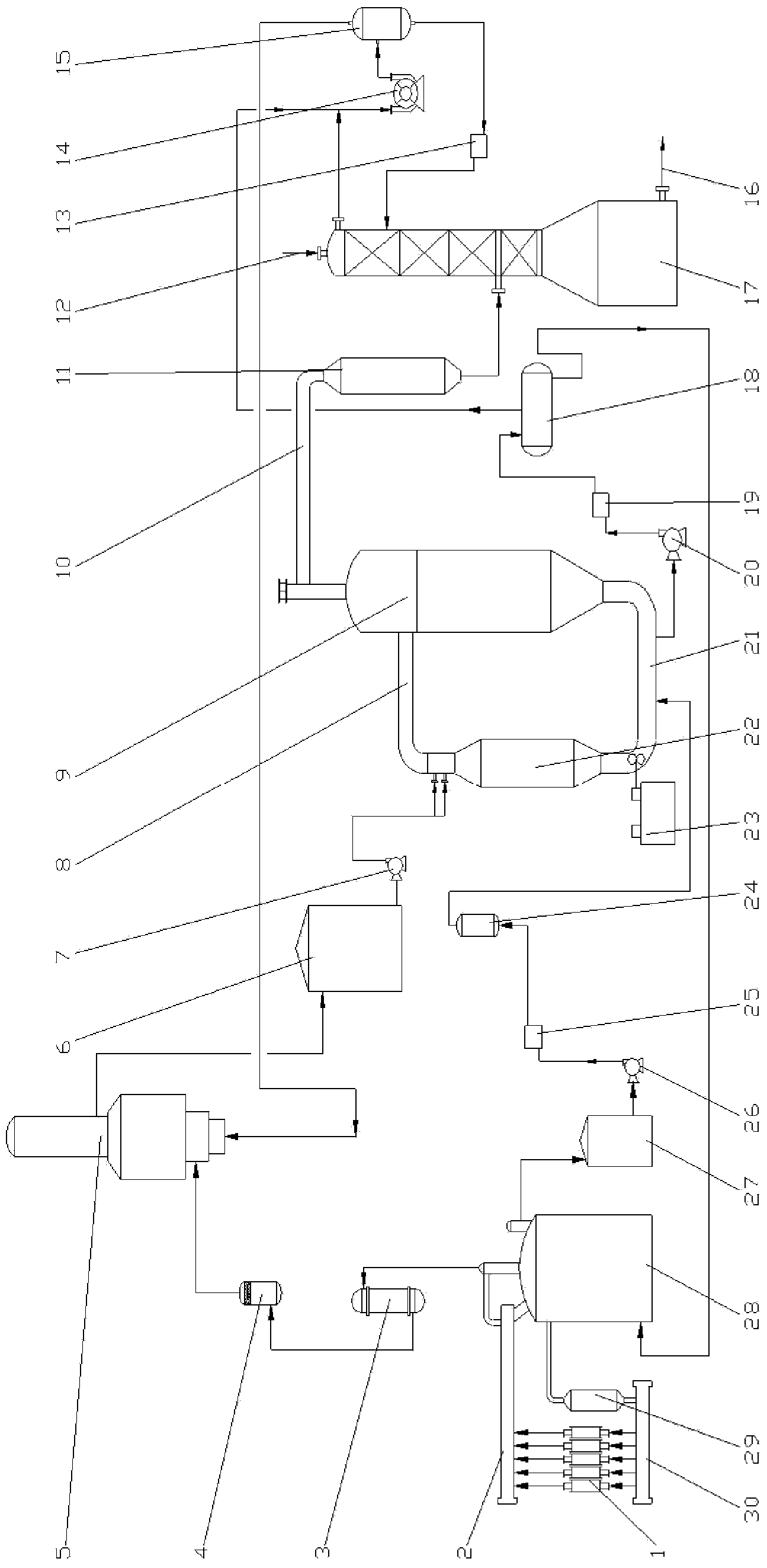

Method used

Image

Examples

Embodiment 1

[0033] The concentrated sodium chlorate solution sent from the electrolytic cell is filtered and injected into the generator to form a reaction mother liquid, which circulates in the generator and the circulation pipeline under the action of the circulating pump. Concentrated sodium chlorate solution flow rate 22.5m 3 / h, density 1406kg / m 3 , the concentration of sodium chlorate is 538g / L, the concentration of sodium chloride is 119g / L, and the concentration of sodium dichromate is 3.99g / L. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 73.5°C. The weight concentration that hydrochloric acid preparation system sends is 31.91% hydrochloric acid (density 1150kg / m 3 ) to the nozzle at the throat of the circulation pipe on the generator to inject into the generator, and the flow rate of adding hydrochloric acid is 5.9m 3 / h, sodium chlorate is reacted with hydrochloric acid to produce chlorine dioxide and chlorine ga...

Embodiment 2

[0035] The concentrated sodium chlorate solution sent from the electrolytic cell is filtered and injected into the generator to form a reaction mother liquid, which circulates in the generator and the circulation pipeline under the action of the circulation pump. Concentrated sodium chlorate solution flow rate 16.07m 3 / h, density 1333kg / m 3 , the concentration of sodium chlorate is 510g / L, the concentration of sodium chloride is 110g / L, and the concentration of sodium dichromate is 3.99g / L. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 72°C. The weight concentration that hydrochloric acid preparation system sends is 31% hydrochloric acid (density 1145kg / m 3 ) to the nozzle at the throat of the circulation pipe on the generator to inject into the generator, and the flow rate of adding hydrochloric acid is 4.21m 3 / h, sodium chlorate is reacted with hydrochloric acid to produce chlorine dioxide and chlorine gas, ...

Embodiment 3

[0037] The concentrated sodium chlorate solution sent from the electrolytic cell is filtered and injected into the generator to form a reaction mother liquid, which circulates in the generator and the circulation pipeline under the action of the circulation pump. Concentrated sodium chlorate solution flow rate 12.86m 3 / h, density 1260kg / m 3 , the concentration of sodium chlorate is 482g / L, the concentration of sodium chloride is 101g / L, and the concentration of sodium dichromate is 3.99g / L. Steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 70°C. The weight concentration that hydrochloric acid preparation system sends is 30% hydrochloric acid (density 1140kg / m 3 ) to the nozzle at the throat of the circulation pipe on the generator to inject into the generator, and the flow rate of adding hydrochloric acid is 3.37m 3 / h, sodium chlorate is reacted with hydrochloric acid to produce chlorine dioxide and chlorine gas, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com