Method for recovering sodium dichromate form chromium-containing electroplating sludge

A sodium dichromate and sodium chromate-containing technology, applied in chromate/dichromate, sludge treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution of ammonia nitrogen and strong acidity of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

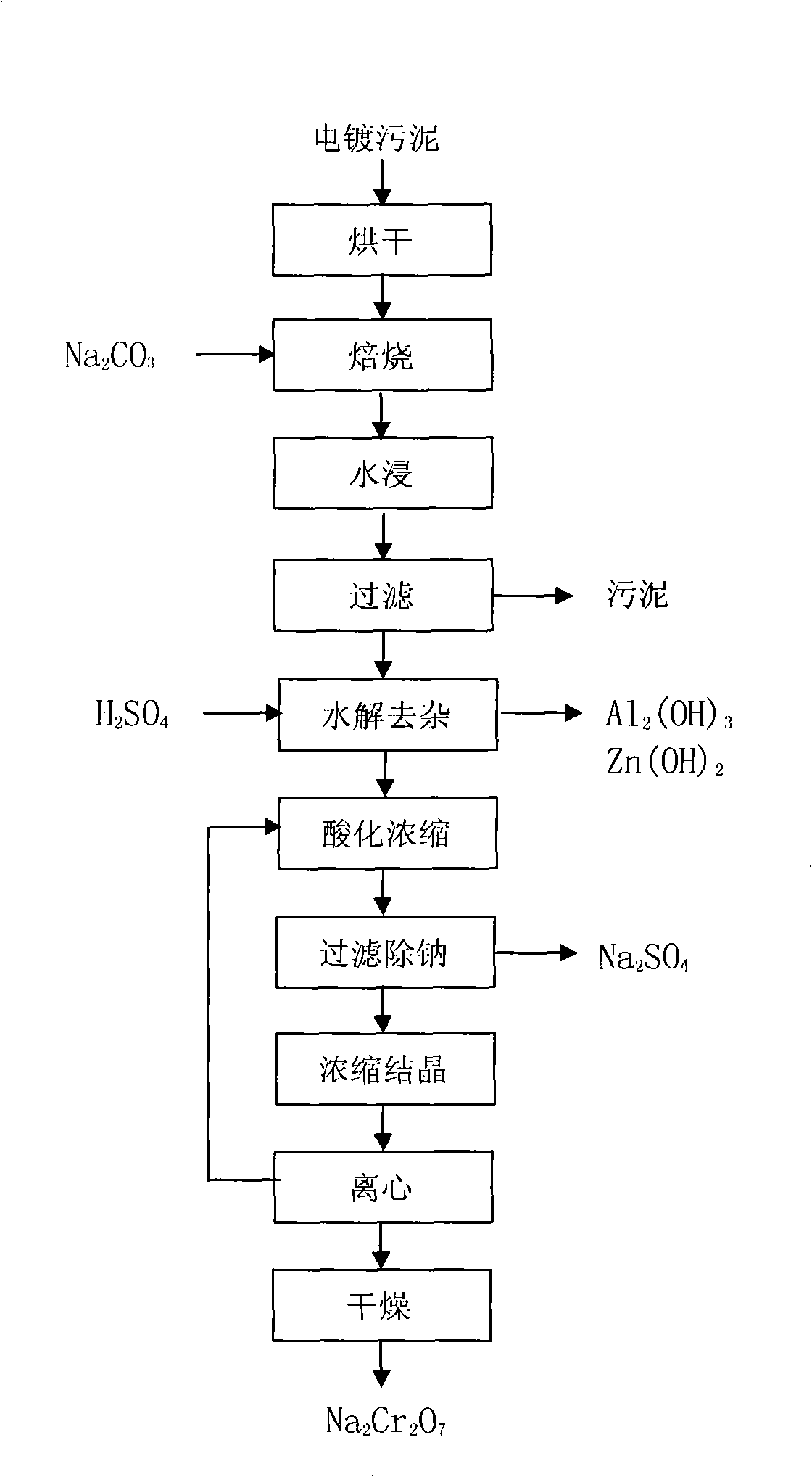

Image

Examples

Embodiment Construction

[0034] (1) Sodium oxidation of electroplating sludge

[0035] Take chromium-containing electroplating sludge, and the measured chromium content is 8.9%, with Na 2 CO 3 After being fully mixed with it at a weight ratio of 1:1, it is roasted on a muffle furnace at a roasting temperature of 600-650°C for 2 hours; after taking it out, soak it in water 10 times its weight to dissolve sodium chromate (Na 2 CrO 4 ), soaking time in water for 1 hour; filter and separate the sludge, and filter out the sodium chromate solution.

[0036] (2), impurity removal

[0037]Adjust the pH of the filtered sodium chromate solution to 7.5, hydrolyze at a temperature of 90-95°C to form flocculent Zn and Al hydroxides, and filter to remove zinc hydroxide and aluminum hydroxide;

[0038] Then add sulfuric acid to the filtrate to adjust the pH to 4 ± 0.1, convert sodium chromate into sodium dichromate, and heat and concentrate the solution to 20% of the original volume, precipitate sodium sulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com