Martensitic stainless steel cementation method and product thereof

A martensitic stainless steel and carburizing technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem of difficulty in ensuring the safety of aircraft, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now take the carburizing heat treatment of 1Cr11Ni2W2MoVA martensitic stainless steel as an example to describe the present invention in detail.

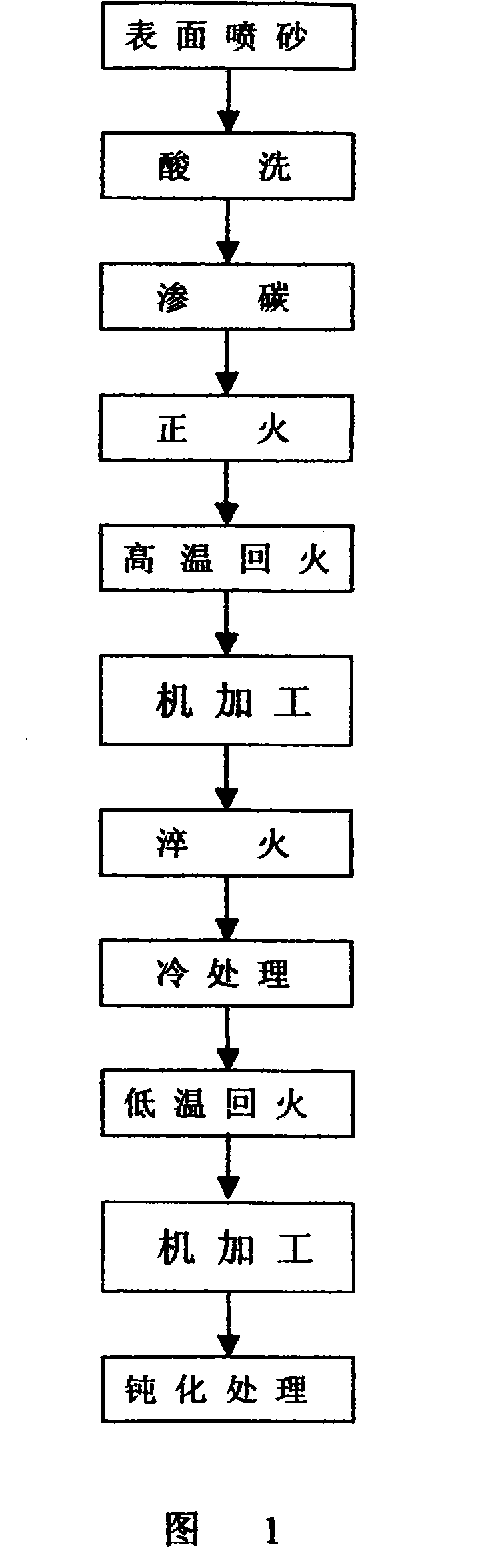

[0026] The martensitic stainless steel material is roughly machined into semi-finished parts, leaving a finishing allowance. Then follow the steps shown in Figure 1 for processing:

[0027] 1. Surface pretreatment

[0028] Sandblast the surface of the semi-finished part to remove oil and destroy the passivation film on the part surface; if necessary, wash the part with 10% phosphoric acid by volume to further corrode the residual passivation film and completely remove it. The chemical reaction is as follows:

[0029] 8H 3 PO 4 +3Fe 3 o 4 →6Fe(PO 4 )+Fe 3 (PO 4 ) 2 +12H 2 o

[0030] h 3 PO 4 +Fe→Fe 3 (PO 4 ) 2 +H 2 ↑

[0031] 3H 2 +Cr 2 o 3 →2Cr+3H 2 o

[0032] The removal of the surface passivation film must be thorough, otherwise it will seriously affect the subsequent carburization. The passivation fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com