Chlorine dioxide oxidizing agent supply system for boiler flue gas denitration and technology thereof

A boiler flue gas and chlorine dioxide technology, applied in the field of flue gas denitrification, can solve the problems of inconvenient process design and equipment selection, unfavorable popularization and application, etc., and achieve the effect of small space occupation, convenient use and continuous supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

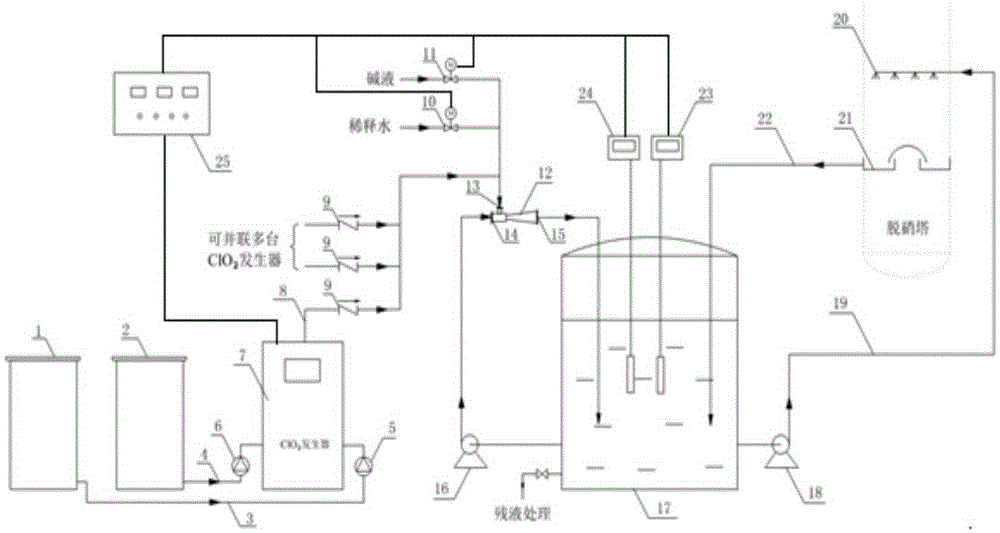

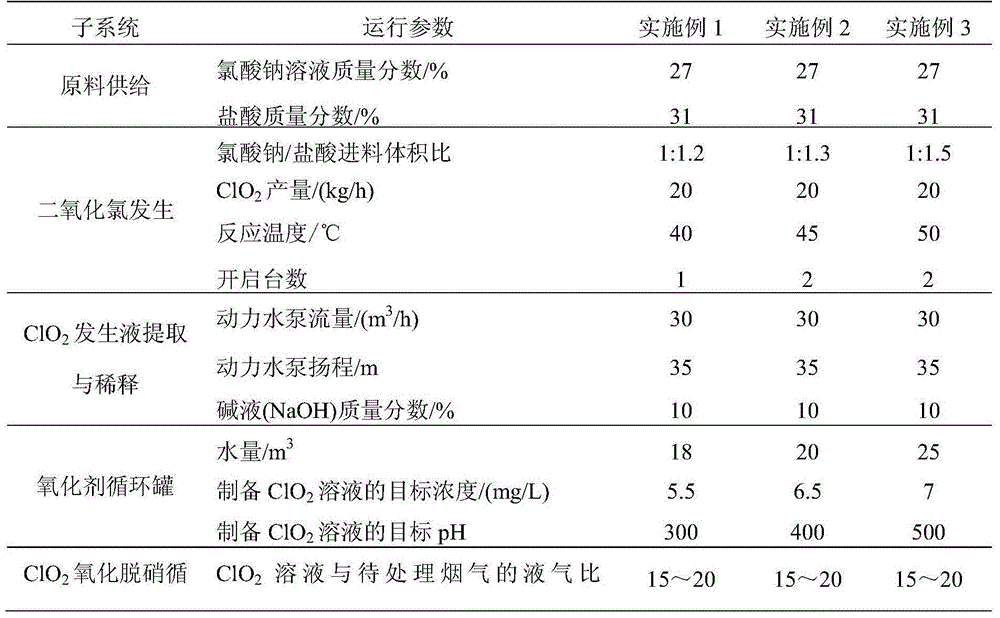

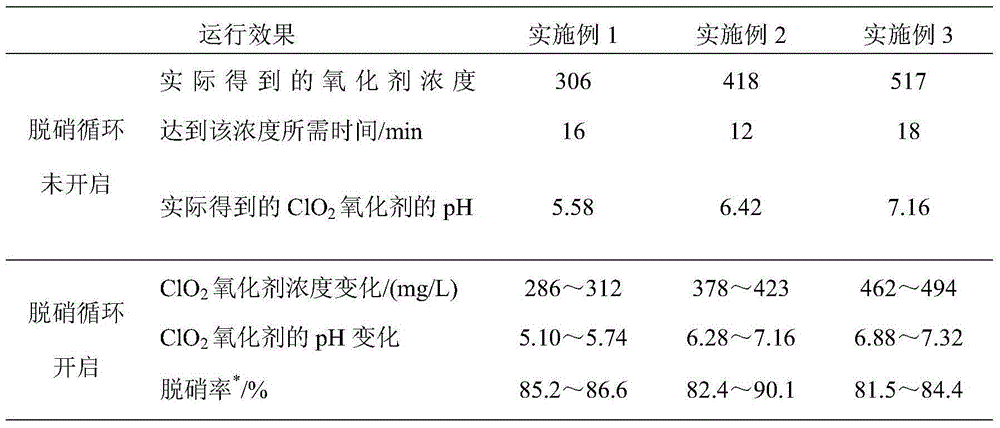

[0043] According to the boiler flue gas denitrification chlorine dioxide oxidant supply system described in Figure 1, run with the operating parameters listed in Table 1 Example 1, the concentration and pH of the chlorine dioxide oxidant solution obtained and according to Chinese patent CN201420088330.6 The data such as the denitrification effect of the denitrification device are shown in Table 2.

Embodiment 2

[0045] According to the boiler flue gas denitrification chlorine dioxide oxidant supply system described in Figure 1, run with the operating parameters listed in Table 1 Example 2, the concentration and pH of the chlorine dioxide oxidant solution obtained and according to Chinese patent CN201420088330.6 The data such as the denitrification effect of the denitrification device are shown in Table 2.

Embodiment 3

[0047] According to the boiler flue gas denitrification chlorine dioxide oxidant supply system described in Figure 1, run with the operating parameters listed in Table 1 Example 3, the concentration and pH of the chlorine dioxide oxidant solution obtained and according to Chinese patent CN201420088330.6 The data such as the denitrification effect of the denitrification device are shown in Table 2.

[0048] The data of table 2 operation result shows, the ClO that embodiment 1~3 is set 2 The target concentrations of the solutions are 300mg / L, 400mg / L and 500mg / L respectively, and the set target pHs are 5.5, 6.5 and 7 respectively. Under the operating parameters of each embodiment, when the oxidation and denitrification cycle is not started, the systems operate separately 16min, 12min and 18min can reach the respective target concentration and pH. After the oxidation and denitration cycle is started, the ClO 2 Although the solution concentration and pH are changing to a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com