Chlorine dioxide generator

A chlorine dioxide generator technology, applied in chlorine oxidation, chemistry, etc., can solve the problems of short reaction residence time, low conversion rate of raw materials, low purity of chlorine dioxide, etc., to improve conversion rate and product yield, The effect of reducing the content of active ingredients and facilitating storage, transportation and sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of high-concentration and high-purity chlorine dioxide is as follows: sodium chlorate solution is used as an oxidizing agent, and 27% hydrogen peroxide solution is used as a reducing agent to react in 20% sulfuric acid medium. The proportion of raw materials entering NaClO 3 :H 2 o 2 :H 2 SO 4 =2:1:1, the reaction time is controlled to be more than 1 hour, the reaction temperature is 50°C, and the negative pressure is 0.01Mpa.

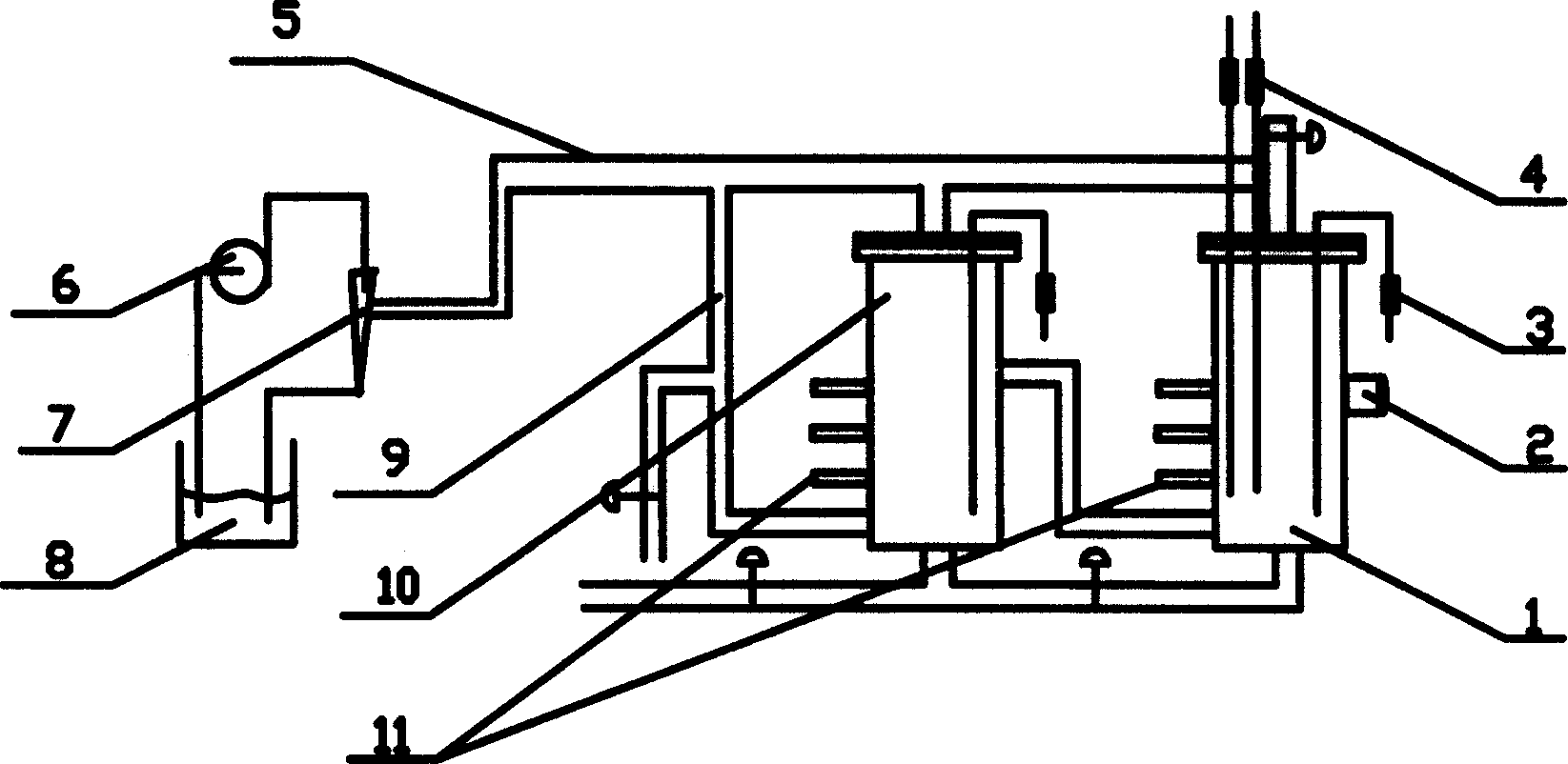

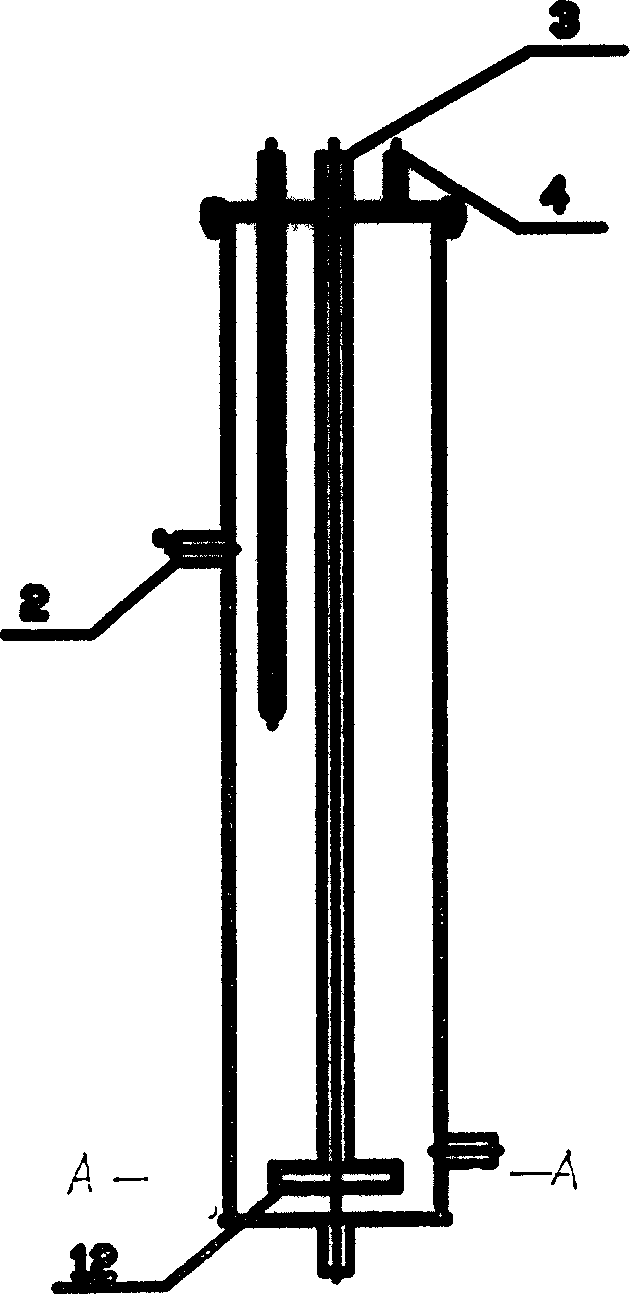

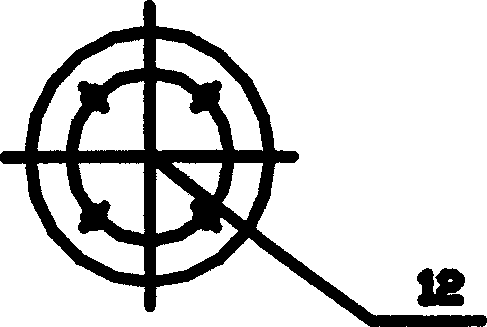

[0030] Raw materials sodium chlorate, hydrogen peroxide and sulfuric acid enter the reactor 1 in proportion from the top autosampler 4 of the main reactor 1, and react after being fully mixed with the air coming out through the air flow meter 3 and the air distributor 12 to form high Concentrated high-purity chlorine dioxide solution. The saturated chlorine dioxide solution is stirred by air, and small bubbles escape from the reaction solution. The incompletely reacted liquid in the main reactor 1 enters the auxiliar...

Embodiment 2

[0032] The preparation method of high-concentration and high-purity chlorine dioxide is as follows: sodium chlorate solution is used as an oxidizing agent, and 30% hydrogen peroxide solution is used as a reducing agent to react in 50% sulfuric acid medium. The proportion of raw materials entering NaClO 3 :H 2 o 2 :H 2 SO 4 =6:4:3, the reaction time is controlled to be more than 1 hour, the reaction temperature is 70°C, and the negative pressure is 0.01Mpa.

[0033] The raw materials sodium chlorate, hydrogen peroxide and sulfuric acid enter the reactor 1 in proportion from the autosampler 4 at the top of the main reactor 1, and react after being fully mixed with the air coming out of the air flow meter 3 and the air distributor 12 to generate a high concentration High-purity chlorine dioxide solution. The saturated chlorine dioxide solution is stirred by air, and small bubbles escape from the reaction solution. The incompletely reacted liquid in the main reactor 1 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com