Method for producing chlorine dioxide with high purity by adopting combined reducing agent

A chlorine dioxide and reducing agent technology, which is applied in the direction of chlorine oxidation, can solve the problems of increased cost, low conversion rate, and large proportion of chlorine gas, and achieve the effects of reducing production costs, increasing conversion rate, and reducing the amount of chlorine gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

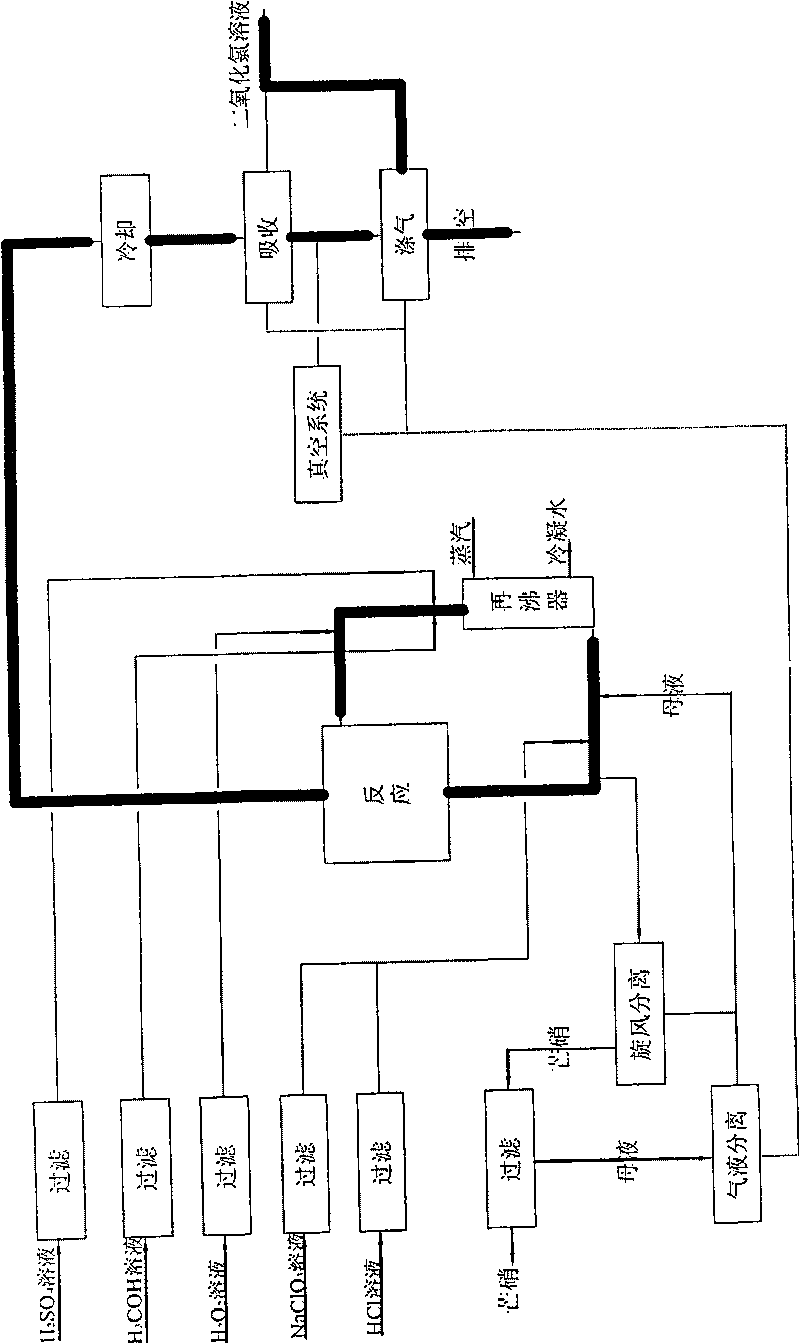

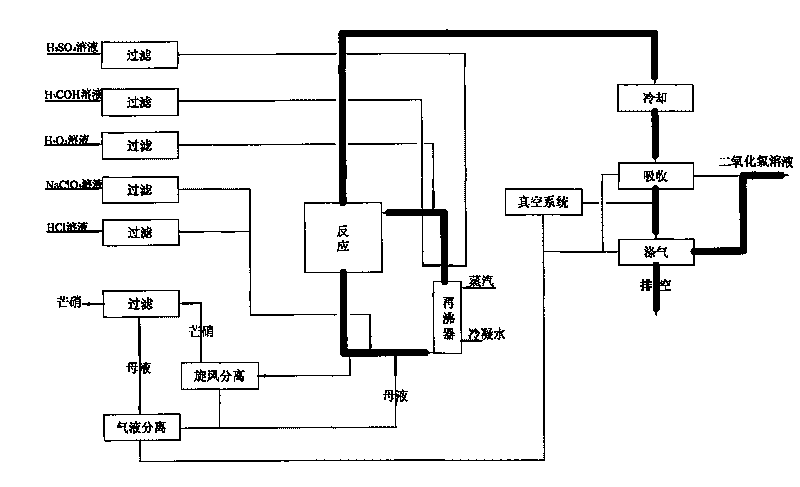

Method used

Image

Examples

Embodiment 1

[0032] 108kg of concentrated sulfuric acid with a weight concentration of 98% and 547kg of sodium chlorate solution with a weight concentration of 30% are filtered and injected into the generator to form a reaction mother liquor, which circulates in the generator circulation pipeline under the action of a circulation pump and keeps the reaction mother liquor The acidity is 8.0-8.2N and the sodium chlorate content is 158-266g / l. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 68-78°C. 52.5kg by weight of 20% methanol, 12.5kg by weight of 30% hydrogen peroxide and 2.5kg by weight of 30% hydrochloric acid were injected into the generator with a nozzle to generate chlorine dioxide. The generator maintains a vacuum condition at a pressure of 120 mm Hg, and the vacuum is generated by two Venturi devices pumped with medium pressure steam to create a vacuum. Under the condition of negative pressure, the temperature of the m...

Embodiment 2

[0034] 108kg of concentrated sulfuric acid with a weight concentration of 98% and 547kg of sodium chlorate solution with a weight concentration of 30% are filtered and injected into the generator to form a reaction mother liquor, which circulates in the generator circulation pipeline under the action of a circulation pump and keeps the reaction mother liquor The acidity is 8.0-8.2N and the sodium chlorate content is 158-266g / l. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 68-78°C. 67.5kg by weight of 20% methanol, 3.5kg by weight of 30% hydrogen peroxide and 1.5kg by weight of 30% hydrochloric acid were injected into the generator with a nozzle to generate chlorine dioxide. The generator maintains a vacuum condition at a pressure of 120 mm Hg, and the vacuum is generated by two Venturi devices pumped with medium pressure steam to create a vacuum. Under the condition of negative pressure, the temperature of the mi...

Embodiment 3

[0036] 108kg of concentrated sulfuric acid with a weight concentration of 98% and 547kg of sodium chlorate solution with a weight concentration of 30% are filtered and injected into the generator to form a reaction mother liquor, which circulates in the generator circulation pipeline under the action of a circulation pump and keeps the reaction mother liquor The acidity is 8.0-8.2N and the sodium chlorate content is 158-266g / l. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 68-78°C. 64.5kg concentration of 20% methanol by weight, 5kg concentration of 30% hydrogen peroxide and 2kg concentration of 30% hydrochloric acid were injected into the generator with a nozzle to make the reaction generate chlorine dioxide. The generator maintains a vacuum condition at a pressure of 120 mm Hg, and the vacuum is generated by two Venturi devices pumped with medium pressure steam to create a vacuum. Under the condition of negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com