Chlorine dioxide generating system

A chlorine dioxide and generation system technology, applied in chlorine oxide, chlorine/hydrogen chloride and other directions, can solve problems such as incomplete reaction and waste of reactants, and achieve the effect of saving resources and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

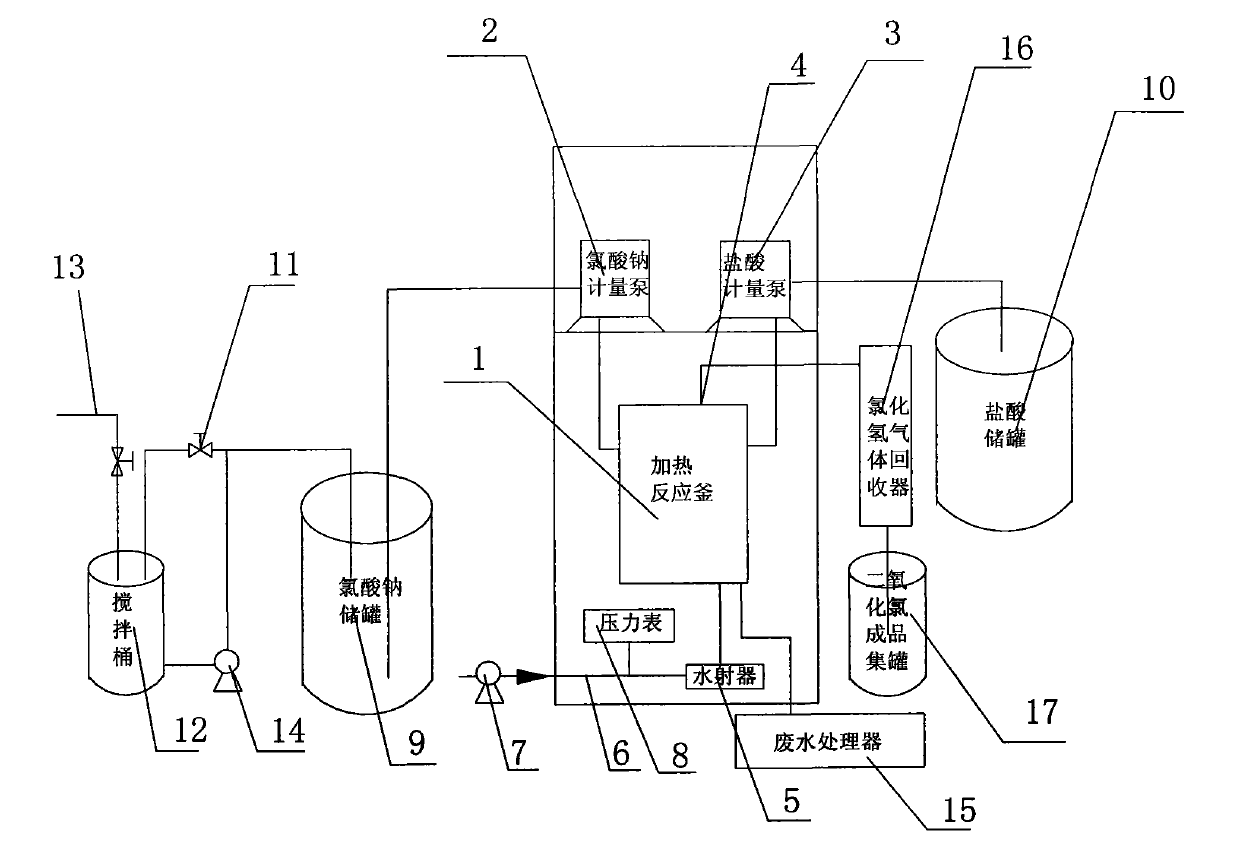

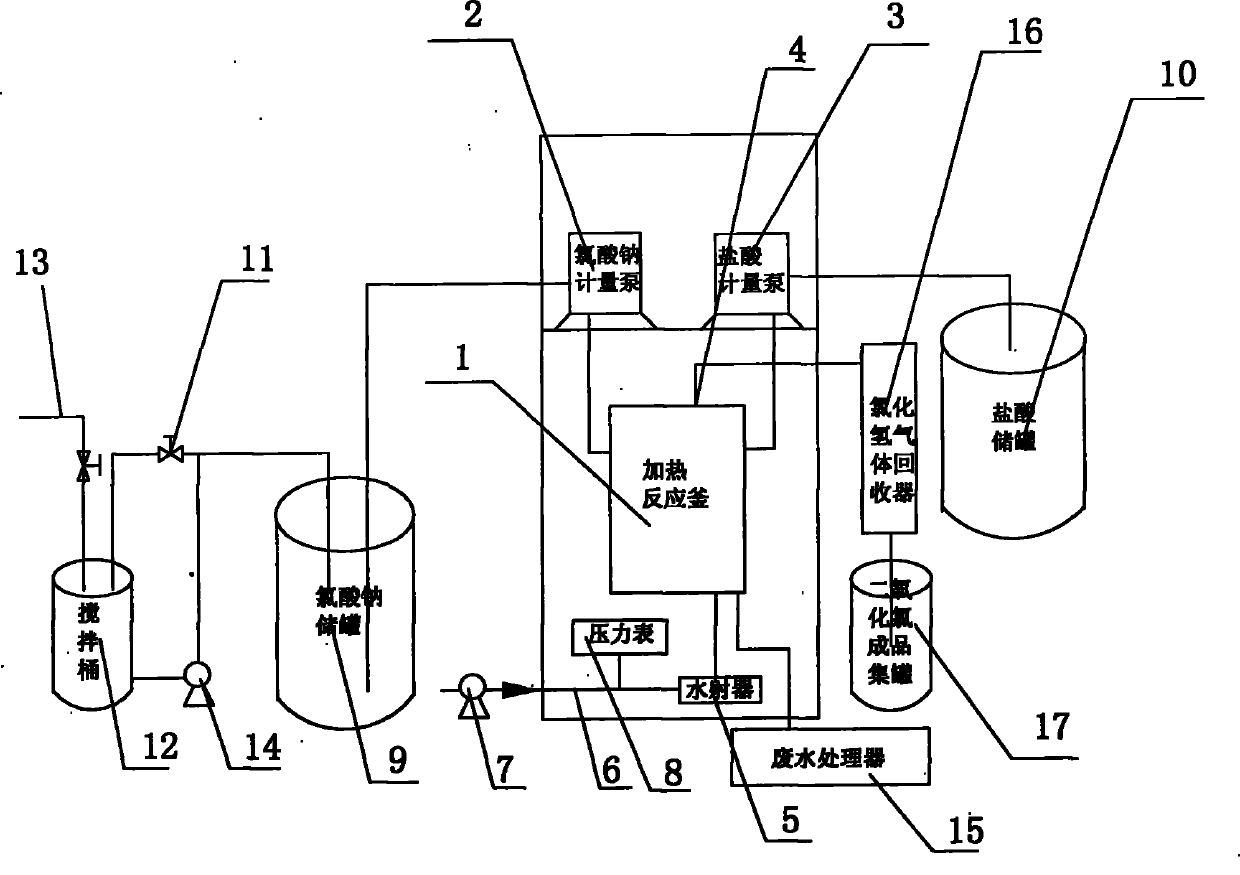

[0012] Such as figure 1 As shown, a kind of chlorine dioxide generating system of the present invention comprises a heating reactor 1, and the two ends of the heating reactor 1 are connected with the sodium chlorate metering pump 2 and the hydrochloric acid metering pump 3, and the reaction product is opened at the top of the heating reactor 1 Outlet 4, the bottom of the heating reactor 1 is connected to the water injector 5, the water injector 5 is connected to the system water inlet circulation pump 7 through the pipeline 6, the pressure gauge 8 is installed on the pipeline 6, the sodium chlorate metering pump 2 is connected to the sodium chlorate The storage tank 9 is connected, the hydrochloric acid metering pump 3 is connected with the hydrochloric acid storage tank 10, the sodium chlorate storage tank 9 is connected with the mixing tank 12 through the manual valve 11, the upper end of the mixing tank 12 is connected with the tap water pipeline 13, and the bottom of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com