A kind of preparation method of high pressure resistant solid polymer electrolyte

A solid polymer and electrolyte technology, applied in solid electrolytes, electrolytes, non-aqueous electrolytes, etc., can solve the problems of solid electrolytes that cannot work at room temperature, low room temperature ionic conductivity, and vaporization of organic electrolytes, so as to improve energy density and The effect of safety, high cycle capacity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve zinc oxide and boric acid in water at a molar ratio of 1:3, stir, dry, and place in a 1000°C muffle furnace for calcination for 10 minutes. After the muffle furnace is cooled, the sample is taken out, washed, filtered, and dried to obtain the desired zinc borate nanoparticles.

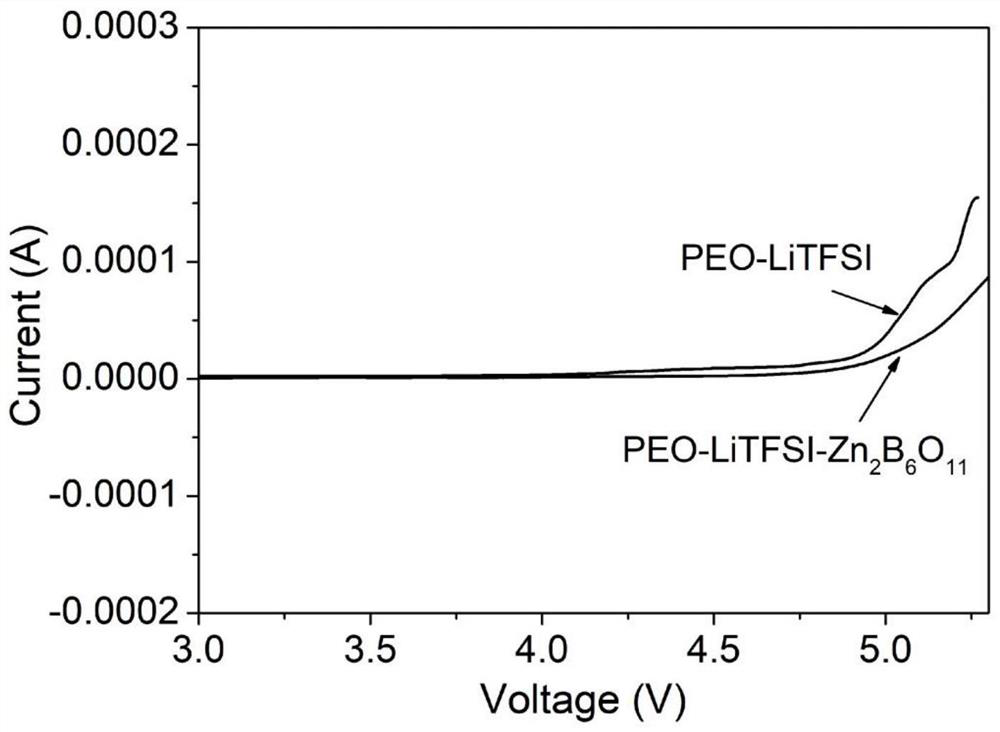

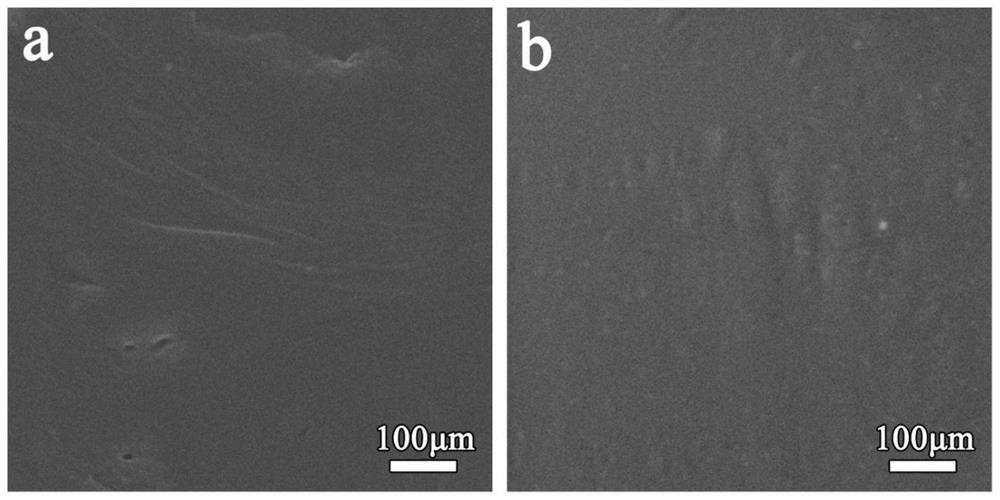

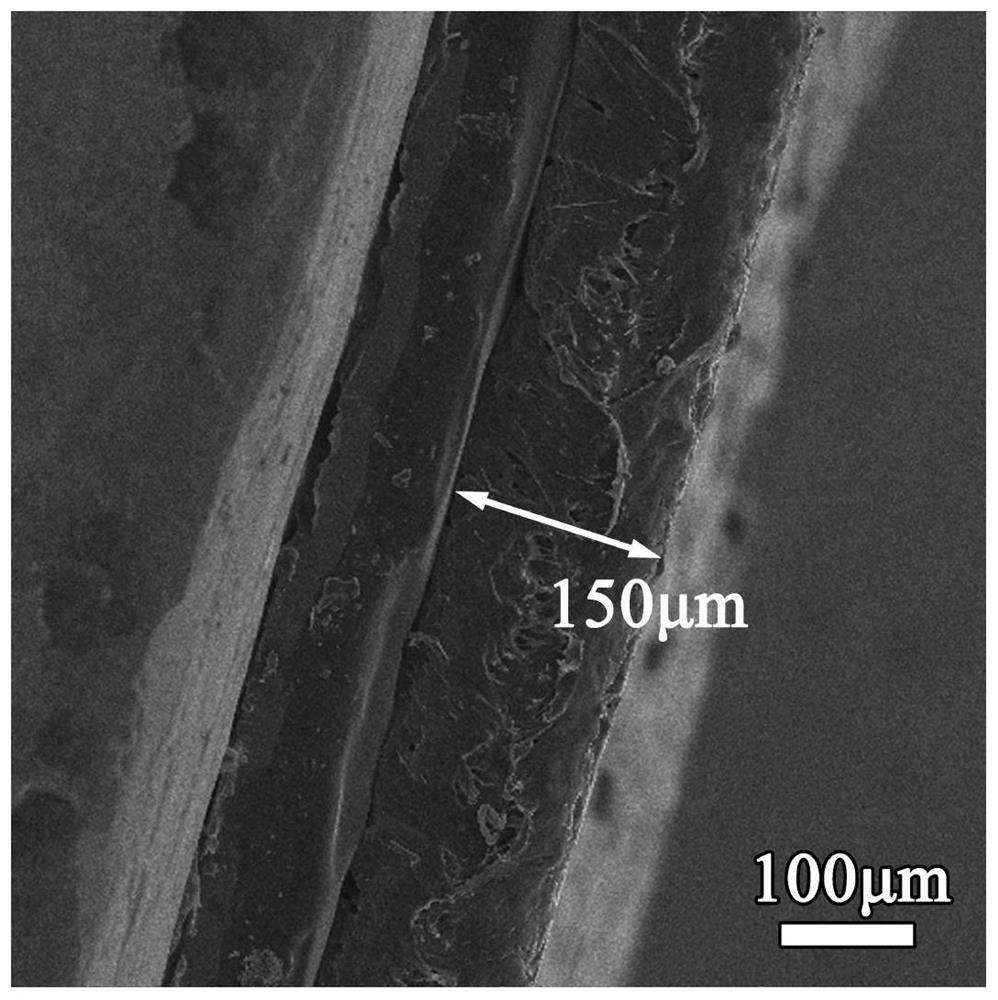

[0035] Dissolve PEO and LiTFSI in an appropriate amount of anhydrous acetonitrile solution at a mass ratio of EO:Li=20:1, and stir to mix them evenly. Zinc borate nanoparticles were added to the mixed solution as zinc borate accounted for 10% of the total mass of PEO and LiTFSI, and vigorously stirred for 48 hours to make it evenly mixed. Among them, the use of LiTFSI must control the water and oxygen content in its environment to be less than 10ppm to prevent the decomposition of salt. The mixed solution was poured into a polytetrafluoroethylene mold and volatilized at 50°C for 24 hours to obtain a solid polymer electrolyte membrane with a certain thickness, which was cut into small d...

Embodiment 2

[0042] Dissolve aluminum nitrate, boric acid, ammonium nitrate, and citric acid in a small amount of water at a molar ratio of 1:1:5:1.4, mix well, and place in a muffle furnace at 1000°C for calcination for 6 minutes. After the muffle furnace is cooled, the sample is taken out, washed, filtered, and dried to obtain the desired aluminum borate nanowhiskers.

[0043]Dissolve PEO and LiTFSI in an appropriate amount of anhydrous acetonitrile solution at a mass ratio of EO:Li=15:1, and stir to mix them evenly. Add aluminum borate nano-whiskers to the mixed solution according to the fact that aluminum borate accounts for 10% of the total mass of PEO and LiTFSI, and stir vigorously for 48 hours to make it evenly mixed. Among them, the use of LiTFSI must control the water and oxygen content in its environment to be less than 10ppm to prevent the decomposition of salt. The mixed solution was poured into a polytetrafluoroethylene mold and volatilized at 50°C for 48 hours to obtain a s...

Embodiment 3

[0050] Calcium chloride and borax were dissolved in water at a molar ratio of 1:2, stirred, dried, and calcined in a muffle furnace at 850°C for 2 hours. After the muffle furnace is cooled, the sample is taken out, washed, filtered, and dried to obtain the desired calcium borate nanowires.

[0051] Dissolve PEO and LiTFSI in an appropriate amount of anhydrous acetonitrile solution at a mass ratio of EO:Li=10:1, and stir to make them evenly mixed. Calcium borate nanowires were added to the mixed solution as calcium borate accounted for 5% of the total mass of PEO and LiTFSI, and vigorously stirred for 24 hours to make it evenly mixed. Among them, the use of LiTFSI must control the water and oxygen content in its environment to be less than 10ppm to prevent the decomposition of salt. The mixed solution was poured into a polytetrafluoroethylene mold and volatilized at 55°C for 48 hours to obtain a solid polymer electrolyte membrane with a certain thickness, which was cut into sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com