Method for reducing surface alkalinity of high-nickel positive electrode material and the positive electrode material and lithium battery

A positive electrode material, surface alkaline technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of affecting the electrochemical performance of materials, destroying the crystal structure of materials, and having no electrochemical activity, so as to improve the electrochemical performance of cycles. Performance, simple process, and the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

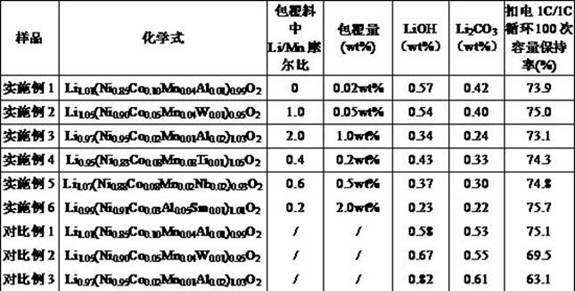

Examples

Embodiment 1

[0021] (1) Add a certain mass of manganese acetate to 100g of propylene glycol, stir at a speed of 2m / s to dissolve it, and form a manganese acetate solution;

[0022] (2) Add 200g Li to the manganese acetate solution 1.01 (Ni 0.85 co 0.10 mn 0.04 al 0.01 ) 0.99 o 2 powder, continue to stir for 10 minutes; then stir and evaporate at a linear speed of 8m / s under vacuum at 80°C for 4h to obtain the dried material;

[0023] (3) The dried mixture was calcined at 500°C in an oxygen atmosphere for 2 hours to obtain Li x MnO 2 Coated high-nickel ternary cathode material.

[0024] The lithium ion battery of the present embodiment is to mix the above-mentioned high-nickel ternary positive electrode material coated, the binder polyvinylidene fluoride PVDF, and the conductive agent carbon black Super P Li in a weight ratio of 94:3:3, and use N- Methylpyrrolidone was used as a solvent to prepare positive electrode slurry. The positive electrode slurry was coated on battery-grade...

Embodiment 2

[0026] (1) Add a certain mass of lithium nitrate and manganese acetate to 400g of ethanol, stir at a speed of 5m / s to dissolve them, and form a mixed solution of lithium nitrate and manganese acetate;

[0027] (2) Add 400g Li to the mixed solution 1.05 (Ni 0.90 co 0.05 mn 0.04 W 0.01 ) 0.95 o 2 powder, continue to stir for 8 minutes; then stir and evaporate at a linear speed of 8m / s for 4h under vacuum at 40°C to obtain the dried material;

[0028] (3) The dried material was calcined in an oxygen atmosphere at 600°C for 2 hours to obtain Li x MnO 2 Coated high-nickel ternary cathode material.

[0029] The lithium-ion battery of this embodiment uses the positive electrode material of this embodiment, and is prepared and tested with reference to the method of Embodiment 1.

Embodiment 3

[0031] (1) Add a certain mass of lithium hydroxide and manganese acetate to 400g of methanol, stir at a speed of 2m / s to dissolve them, and form a mixed solution of lithium hydroxide and manganese acetate;

[0032] (2) Add 100g Li to the mixed solution 0.97 (Ni 0.95 co 0.02 mn 0.01 al 0.02 ) 1.03 o 2 powder, continue to stir for 9 minutes; then, under vacuum conditions at 20°C, stir and evaporate at a linear speed of 8m / s for 2h to obtain the dried material;

[0033] (3) The dried material was calcined in an oxygen atmosphere at 700°C for 2 hours to obtain Li x MnO 2 Coated high-nickel ternary cathode material.

[0034] The lithium-ion battery of this embodiment uses the positive electrode material of this embodiment, and is prepared and tested with reference to the method of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com