Lithium-based high-temperature carbon-absorbing material-modified positive electrode material and preparation method and application thereof

A technology of positive electrode materials and carbon materials, applied in the field of lithium-based high-temperature carbon-absorbing materials modified positive electrode materials, which can solve the problems of complicated procedures, no removal, and inability to solve the side reactions of residual lithium and electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Weigh 1g tetraethyl orthosilicate solution with a silicon concentration of 0.5mol / L, 100mL lithium nitrate solution with a lithium concentration of 0.5mol / L, and 100g ternary cathode material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Stir evenly in a beaker, and air-dry at 200°C to obtain a uniform mixture;

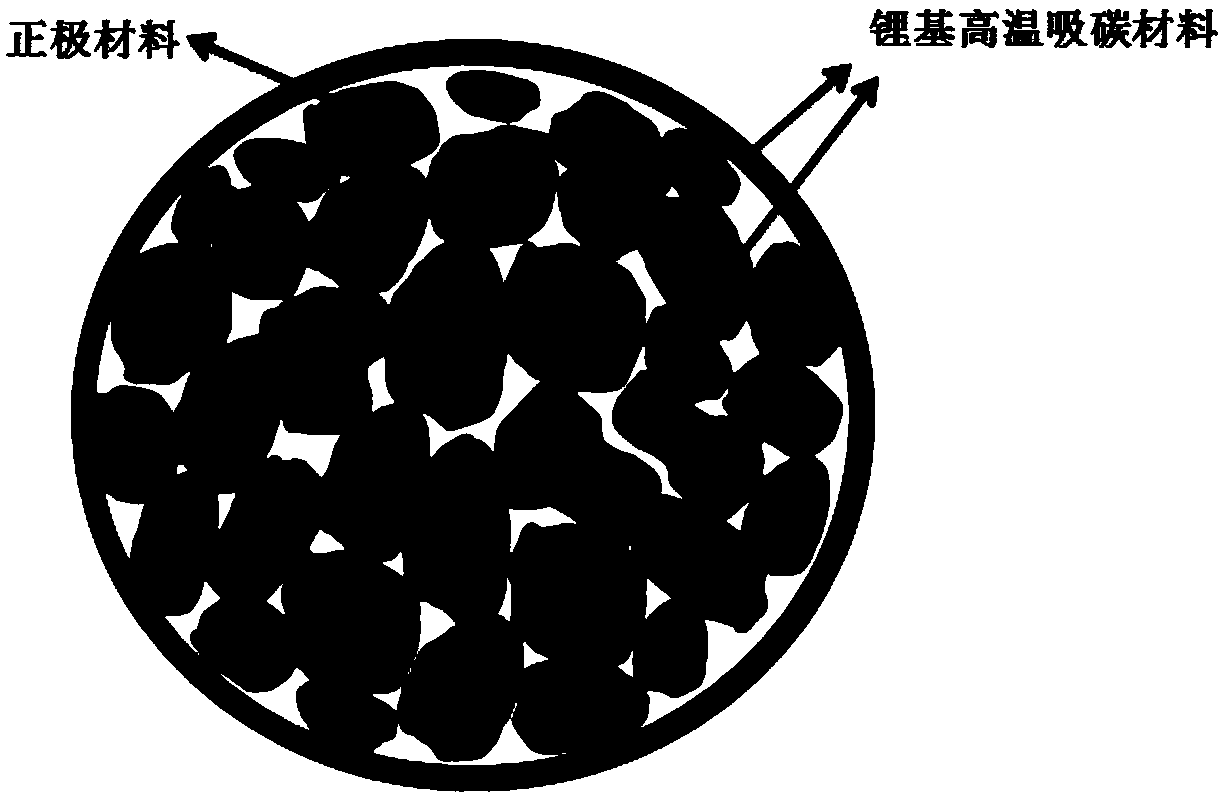

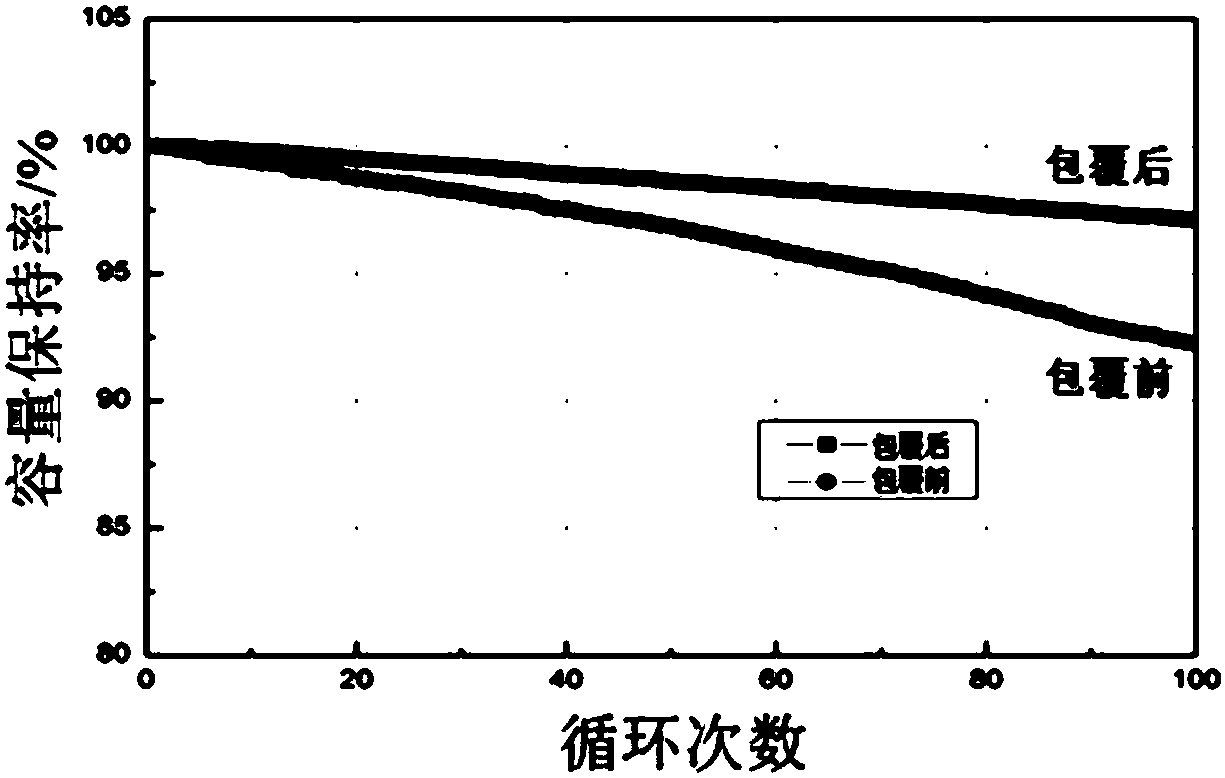

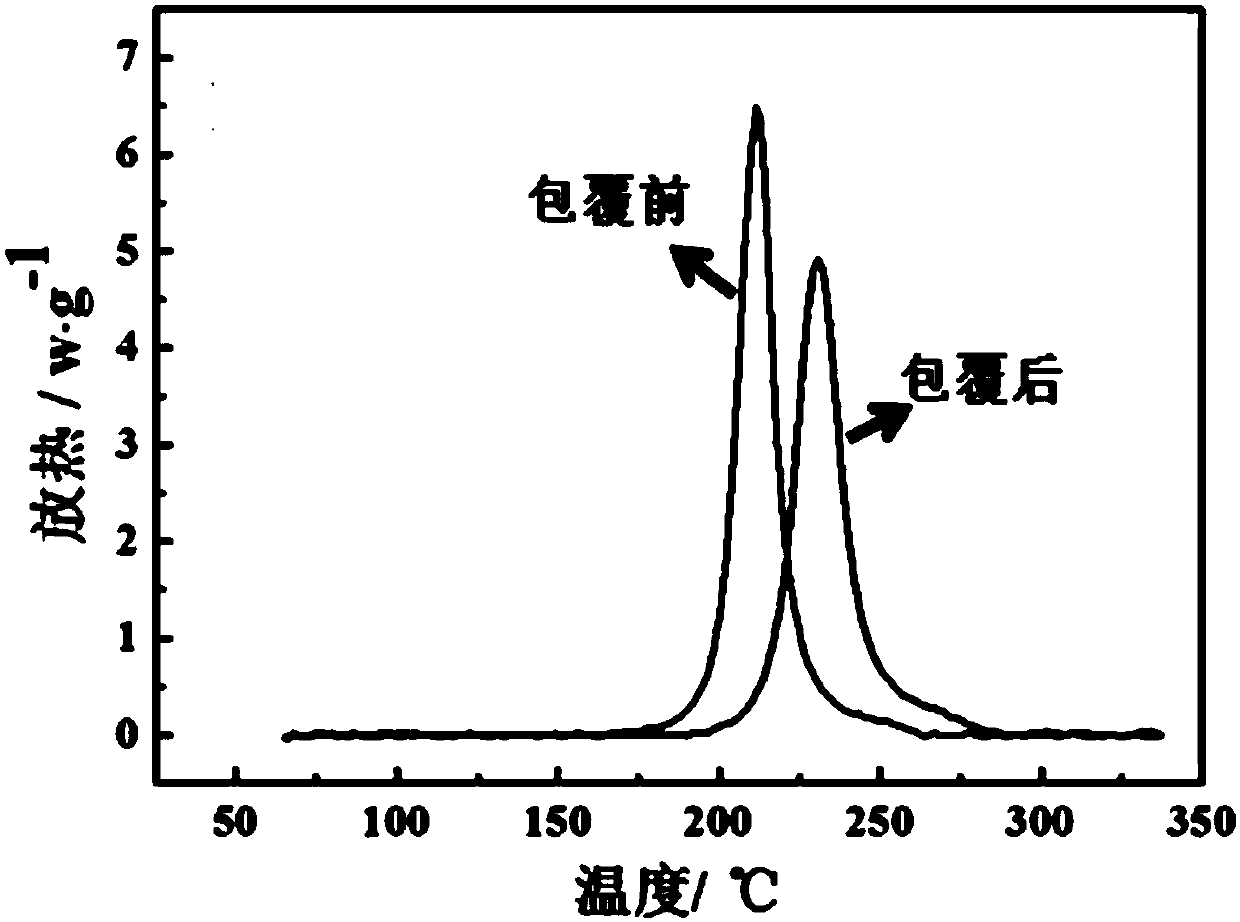

[0067] (2) Take the above mixture and lithium hydroxide monohydrate, the addition of the two makes the molar content of each element in the final product (modified positive electrode material) meet Li 1.05 Ni 0.8 co 0.1 mn 0.1 o 2 According to the standard, the mechanical fusion is uniform, and sintered at a temperature of 800 ° C for 12 hours to obtain a lithium-ion battery ternary layered positive electrode material modified by lithium-based high-temperature carbon-absorbing material lithium silicate (that is, lithium-based high-temperature ), the modified cathode material is composed of cathode material Li 1.05 Ni 0.8 co 0.1 mn 0.1 o 2 and lithium-ba...

Embodiment 2

[0072] (1) Weigh 2g of zirconium oxychloride octahydrate solution with zirconium concentration of 0.25mol / L, 100mL of lithium hydroxide solution with lithium concentration of 0.5mol / L, and 100g of ternary cathode material precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Stir evenly in a beaker, and air-dry at 300°C to obtain a uniform mixture;

[0073] (2) Take the above mixture and lithium hydroxide monohydrate, the addition of the two makes the molar content of each element in the final product (modified positive electrode material) meet Li 1.1 Ni 0.6 co 0.2 mn 0.2 o 2 According to the standard, three-dimensional mixing is uniform, and sintering at 900°C for 12 hours to obtain a lithium-based high-temperature carbon-absorbing material lithium zirconate-modified lithium-ion battery ternary layered positive electrode material (that is, a lithium-based high-temperature carbon-absorbing material modified positive electrode material) , the modified cathode material is composed of cat...

Embodiment 3

[0075] (1) Weigh 3g of tetraethyl orthosilicate solution with silicon concentration of 0.25mol / L, 150mL of lithium nitrate solution with lithium concentration of 1mol / L, and 80g of ternary positive electrode material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Stir evenly in a beaker, and air-dry at 150°C to obtain a uniform mixture;

[0076] (2) Take the above mixture and lithium hydroxide monohydrate, the addition of the two makes the molar content of each element in the final product (modified positive electrode material) meet Li 1.00 Ni 0.8 co 0.1 mn 0.1 o 2 Standard, uniform mechanical fusion, sintering at a temperature of 820 ° C for 14 hours, obtained a lithium-ion battery ternary layered positive electrode material modified by lithium-based high-temperature carbon-absorbing material lithium silicate (that is, lithium-based high-temperature carbon-absorbing material modified positive electrode material ), the modified cathode material is composed of cathode material Li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com