Aluminium and erbium coated high-nickel lithium-ion cathode material and preparation method thereof

A cathode material and lithium ion technology, applied in the field of aluminum and erbium coated high-nickel lithium ion cathode materials and their preparation fields, can solve problems such as uniform coating of metal ions, improve cycle performance at room temperature and high temperature, reduce physical and chemical properties, The effect of reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

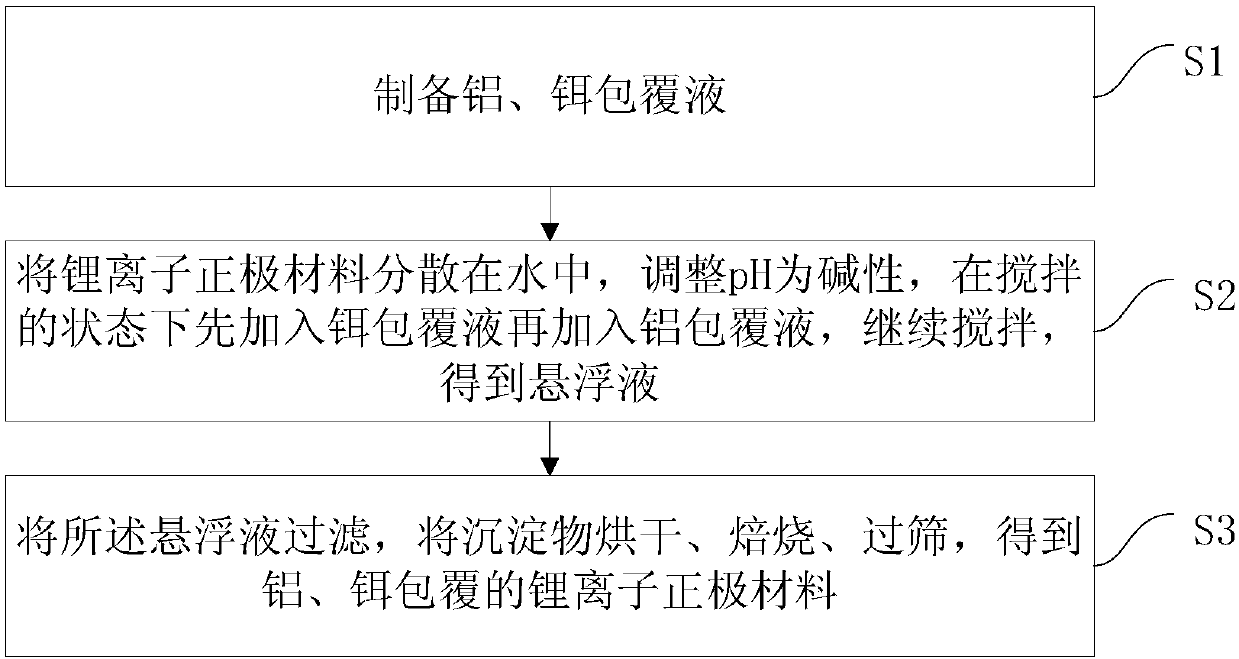

[0024] Such as figure 1 As shown, the preparation method of aluminum, erbium coated high-nickel lithium ion cathode material provided by the invention comprises the following steps:

[0025] Step S1, preparing aluminum and erbium coating solution.

[0026] Specifically, when preparing the aluminum coating solution, the aluminum compound is dissolved in ultrapure water, heated to 45-80° C., and stirred until it is completely dissolved. When preparing the erbium coating solution, dissolve the erbium oxide in the organic acid, heat to 80-100° C., and stir until it is completely dissolved, and the time is 5-12 hours.

[0027] The aluminum compound mentioned here can be aluminum lactate, wherein the added amount of aluminum is 0.1-0.5% of the lithium ion positive electrode material. The erbium oxide is Er 2 o 3 , the organic acid is acetic acid, Er:organic acid=1:3~1:10mol%.

[0028] Step S2, disperse the lithium ion positive electrode material in water, adjust the pH to be al...

Embodiment 1

[0035] (1) First prepare the aluminum coating solution, dissolve 100.9g of aluminum lactate in 500ml of ultrapure water, heat to 60°C, and stir until it is completely dissolved. Next prepare the erbium coating liquid, 23.7gEr 2 o 3 Dissolve in 22.3g of acetic acid, heat to 90°C, and stir until it is completely dissolved for 7 hours. The coating amount of aluminum was 1000 ppm, and the coating amount of erbium was 2000 ppm.

[0036] (2) 10kg LiNi 0.8 co 0.15 mn 0.15 o 2 Put the cathode material into 20kg of ultrapure water, adjust the pH value between 9.5 and 12.5, turn on the stirring paddle, and set the temperature at 45°C. While stirring, first add the erbium coating solution, and finish adding within 5 minutes. Monitor the pH to ensure that the pH is between 8 and 11, then add the aluminum coating solution and continue stirring for 30 minutes.

[0037] (3) Suction filter the above suspension, and dry the filter cake in a vacuum oven at 120° C. for 10 hours. The drie...

Embodiment 2

[0040] (1) First prepare the aluminum coating solution, dissolve 100.9g of aluminum lactate in 300ml of ultrapure water, heat to 60°C, and stir until it is completely dissolved. Next prepare the erbium coating liquid, 47.4gEr 2 o 3Dissolve in 66.9g of acetic acid, heat to 80°C, and stir until it is completely dissolved for 5 hours. The coating amount of aluminum was 1000 ppm, and the coating amount of erbium was 4000 ppm.

[0041] (2) 10kg LiNi 0.88 co 0.09 al 0.03 o 2 Put the cathode material into 20kg of ultrapure water, adjust the pH value between 9.5 and 12.5, turn on the stirring paddle, and set the temperature at 50°C. While stirring, first add the erbium coating solution, and finish adding within 5 minutes. Monitor the pH to ensure that the pH is between 8 and 11, then add the aluminum coating solution and continue stirring for 20 minutes.

[0042] (3) Suction filter the above suspension, and dry the filter cake in a vacuum oven at 100° C. for 10 hours. The drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com