Lithium ion secondary battery cathode material and preparation method thereof

A technology for positive electrode materials and secondary batteries, which is applied in the field of lithium ion secondary battery positive electrode materials and its preparation, and can solve the problems of low-cobalt materials such as rate performance, reduction, and poor kinetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

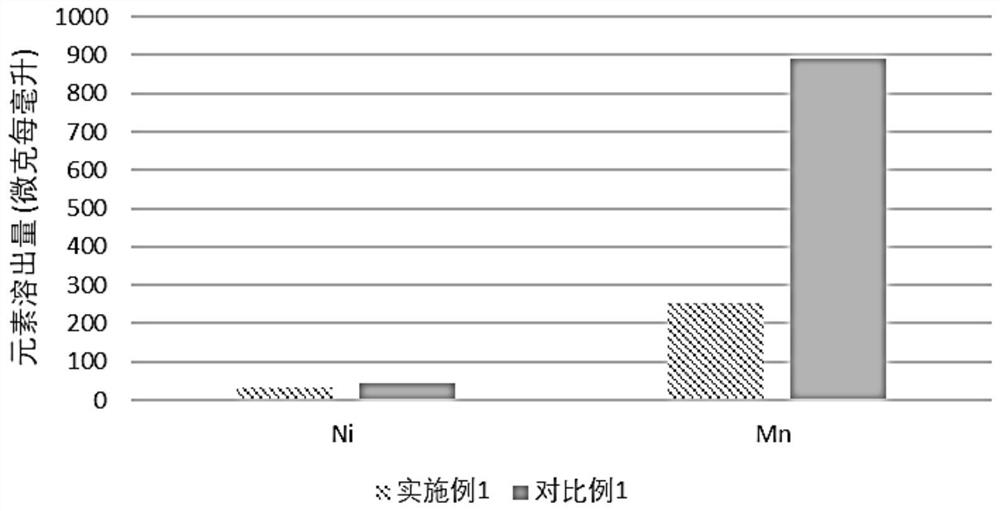

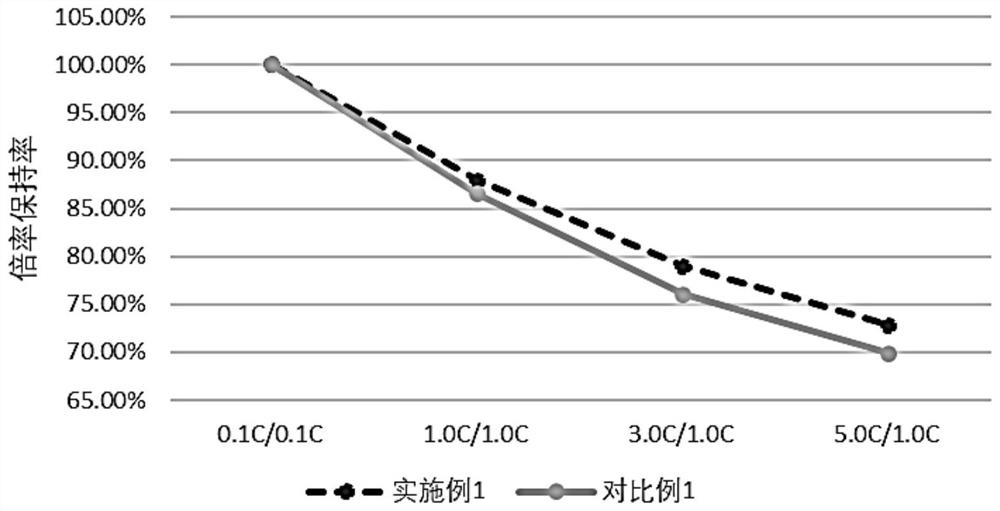

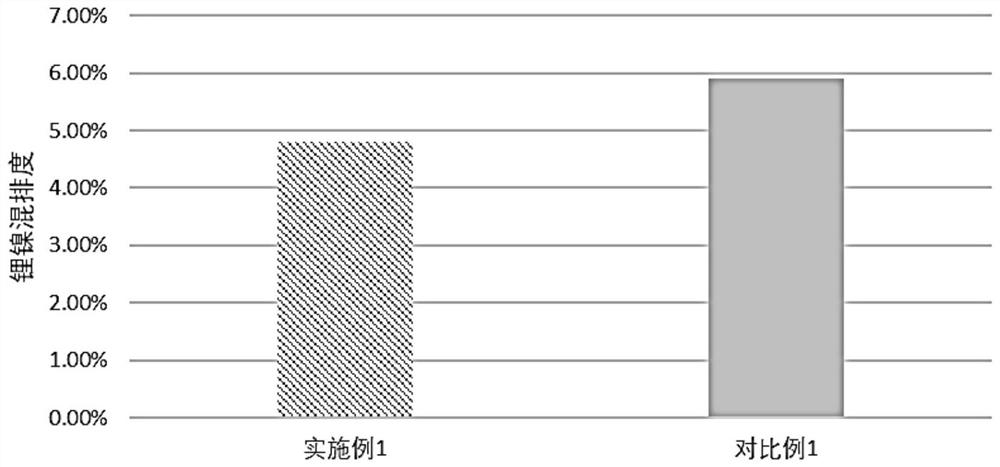

Embodiment 1

[0036] 1) Lithium, nickel, cobalt, and manganese are mixed by ball milling lithium carbonate, nickel acetate, cobalt acetate, and manganese acetate in a molar ratio of 1.10:0.55:0.05:0.40; the mixed materials are placed in a muffle furnace Calcined at 990° C. for 10 h in an air atmosphere, and then crushed and sieved by a jet mill to obtain a core material of nickel cobalt lithium manganese oxide.

[0037] 2) Weighing the first coating material lithium nitrate according to 1.00% of the weight of the core material, mixing the first coating material and the core material at high speed, and sintering the mixed material at 800° C. for 6 hours in an air atmosphere. The sintered material is crushed and screened to obtain intermediate products.

[0038] 3) Weigh the second coating material alumina according to 0.05% of the weight of the intermediate product in step 2), mix the second coating material and the intermediate product at high speed, and sinter the mixed material at 600° C....

Embodiment 2

[0041] 1) Prepare nickel sulfate, cobalt sulfate, magnesium sulfate, and sodium metaaluminate into hydroxide precipitates by co-precipitation method with nickel, cobalt, manganese, and aluminum in a molar ratio of 0.55:0.05:0.39:0.01. After suction filtration Carry out drying; mix the lithium carbonate and the prepared hydroxide precipitation at a high speed with the total content of lithium and metal at a molar ratio of 1.06:1, and place the mixed material in a muffle furnace for calcination at 1000°C for 1 hour in an air atmosphere , and then carry out jet mill crushing and sieving to obtain the core material of nickel cobalt lithium manganese oxide.

[0042] 2) Weighing the first coating material lithium fluoride according to 0.05% of the weight of the core material, mixing the first coating material and the core material at high speed, and sintering the mixed material in an air atmosphere. The sintering temperature of the first stage is 900°C, and the time is 5h. The seco...

Embodiment 3

[0046] 1) Lithium, nickel, cobalt, and manganese are mixed by ball milling lithium carbonate, nickel acetate, cobalt acetate, and manganese acetate in a molar ratio of 1.10:0.60:0.10:0.30; the mixed materials are placed in a muffle furnace Calcined at 650° C. for 20 h in an air atmosphere, and then crushed and sieved by a jet mill to obtain a core material of nickel cobalt lithium manganese oxide.

[0047] 2) Weigh the first coating material sodium hydroxide according to 0.30% of the weight of the core material, mix the first coating material and the core material at high speed, and sinter the mixed material at 800° C. for 6 hours in an air atmosphere. The sintered material is crushed and screened to obtain intermediate products.

[0048] 3) Take by weighing the second coating material vanadium pentoxide and ammonium dihydrogen phosphate according to 1.50% of the weight of the intermediate product in step 2), wherein the molar ratio of vanadium and phosphorus is about 1:1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com