Method for preparing nanocrystalline superstructure tube or rod based on template epitaxial assembly

A superstructure and nanocrystalline technology, applied in the fields of nanotechnology, nanocarbon, nanotechnology, etc. for materials and surface science, can solve the problems of unfavorable nanoparticle assembly, poor structural uniformity, difficult preparation, etc., and achieve orderly structure. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

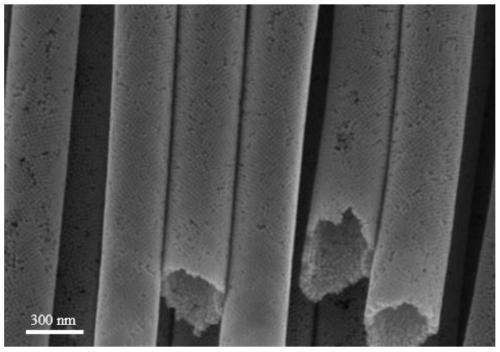

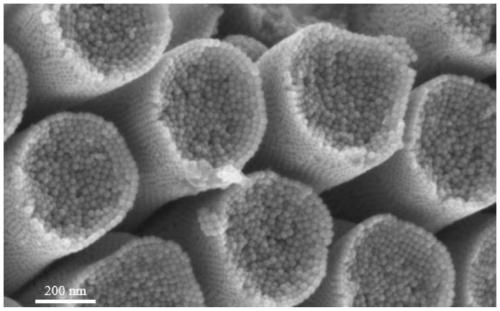

[0026] A method for preparing nanocrystalline superstructure tubes based on template epitaxy assembly, the specific steps are as follows:

[0027] (1) Cubic Fe 3 o 4 Synthesis of Nanocrystals

[0028] A 500 mL three-necked flask was selected, and 18 g of iron oleate, 3.1 g of sodium oleate, 5.5 g of oleic acid, and 40 g of octadecene solvent were added. Under the condition of stirring, after vacuum degassing at 120 °C for one hour, it was heated to 320 °C under the protection of nitrogen atmosphere, and kept at this temperature for two hours. When cooled to room temperature, it was purified by adding ethanol / isopropanol solvent precipitation, and then dispersed in n-hexane to form a stable cubic Fe 3 o 4 Nanocrystalline Colloidal Solution.

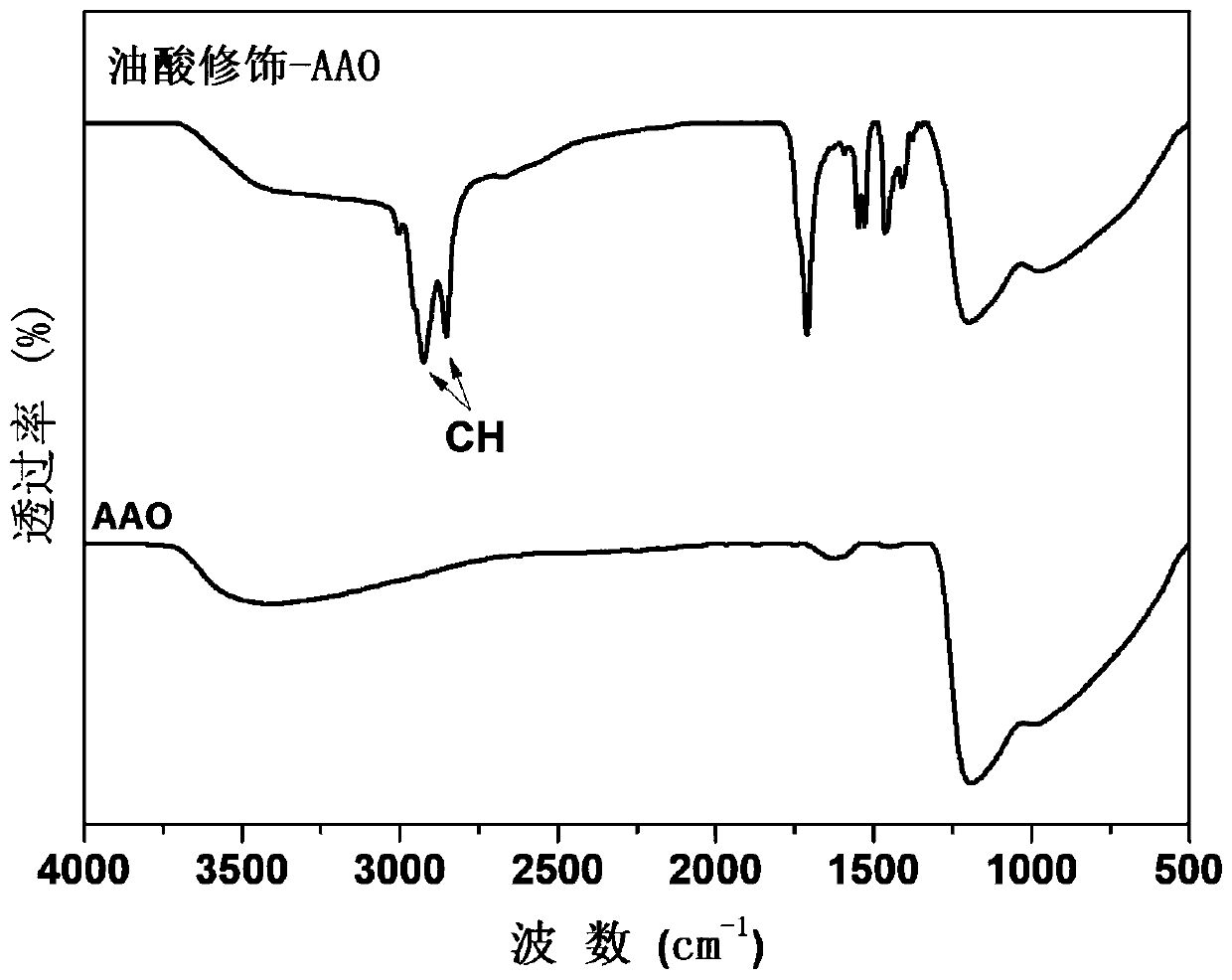

[0029] (2) Surface modification of anodized aluminum template

[0030] Put the initial anodized aluminum template into a n-hexane solution containing 0.2M oleic acid, and let it stand for 6 hours to obtain an oleic acid-modified anod...

Embodiment 2

[0035] A method for preparing nanocrystalline superstructure rods based on template epitaxy assembly, the same as in Example 1, wherein:

[0036] (2) No treatment was performed on the alumina template of the initial prototype.

Embodiment 3

[0038] A method for preparing nanocrystalline superstructure tubes based on template epitaxy assembly, the same as in Example 1, wherein:

[0039] (2) The standing time is 0.1h;

[0040] (3) The assembly temperature is 0°C, and the assembly time is 0.1h;

[0041] (4) The alkaline solution is undiluted concentrated ammonia water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com