Lithium battery anode material and preparation method and application thereof

A technology for positive electrode materials and lithium batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance of high-nickel positive electrode materials, inability to form a uniform coating layer, complicated process, etc., to achieve a suitable large-scale Good for production, good for wrapping, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

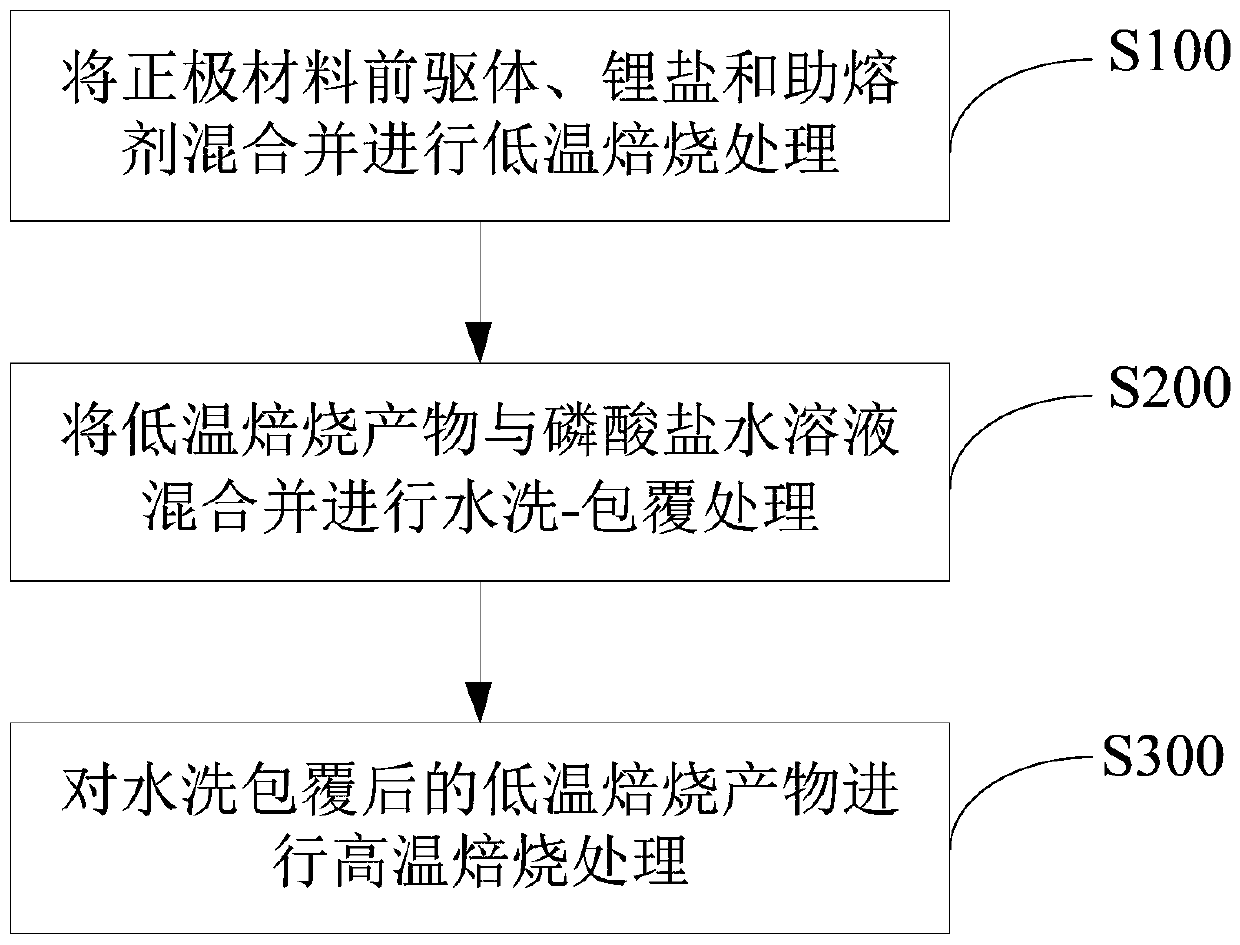

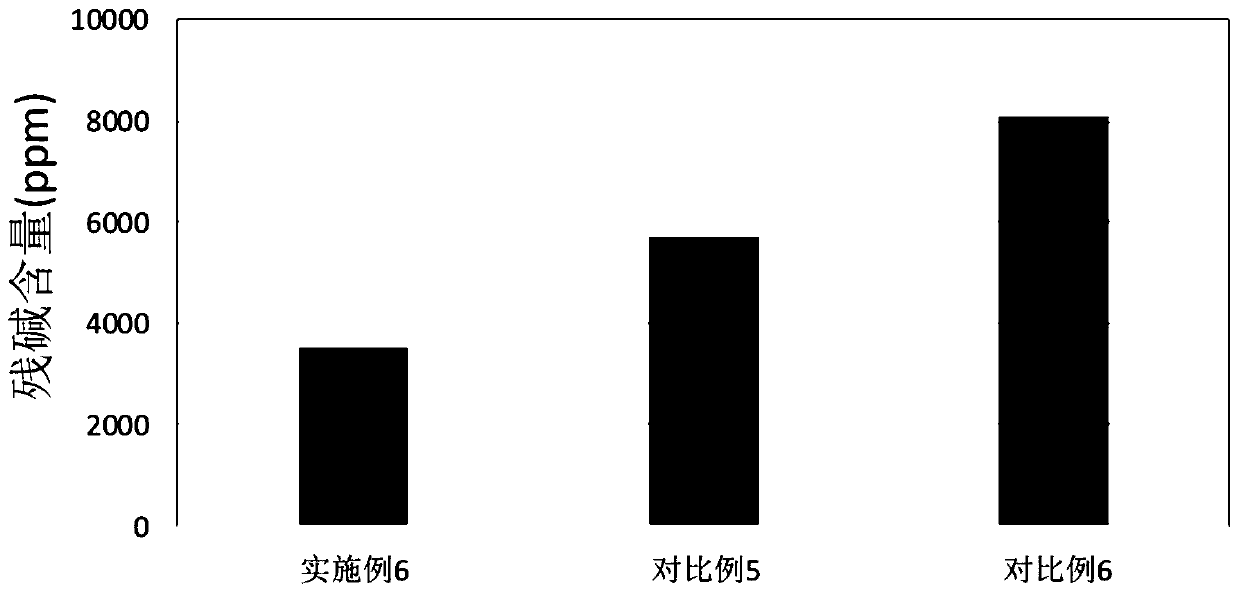

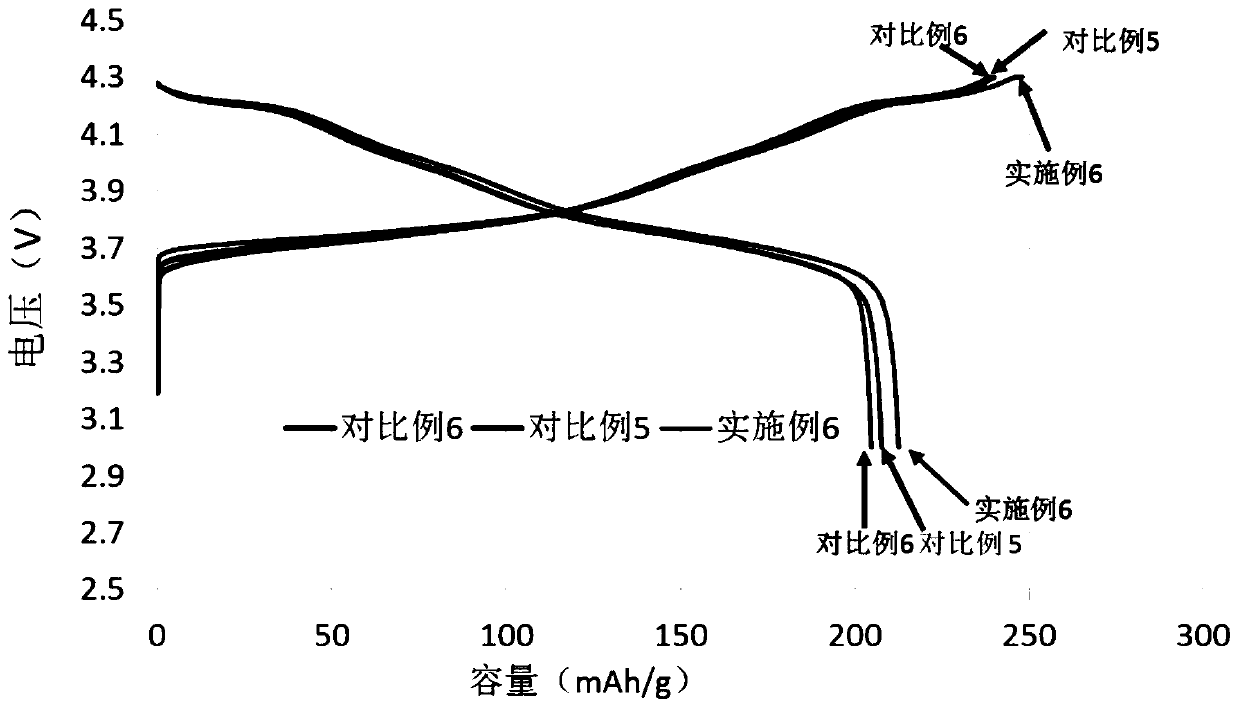

[0044] According to the method for preparing the positive electrode material of the lithium battery according to the above-mentioned embodiments of the present invention, the precursor of the positive electrode material and the lithium salt can be synthesized into an uncoated positive electrode material at a low temperature by using a cosolvent, that is, a low-temperature roasting product; The positive electrode material is mixed and reacted with the phosphate aqueous solution, which not only reduces the residual alkali on the surface of the material, so that the residual alkali content of the finally obtained positive electrode material is not higher than 4000ppm, but also makes the residual lithium on the surface of the material combine with phosphate ions to form a precipitate , and nucleate on the surface of the material, and then through high-temperature calcination, a positive electrode material with a lithium phosphate coating layer on the surface can be finally formed, a...

Embodiment 1

[0050] (1) The positive electrode material precursor (Ni 0.83 Co 0.11 Mn 0.06 )(OH) 2 ), lithium salt LiOH and flux Mg(OH) 2 Mixing and calcining at a low temperature of 200 ° C for 15 h to obtain a low-temperature calcined product, wherein the mass ratio of the cathode material precursor, lithium salt and flux is 100:49:3;

[0051] (2) Combine the low-temperature calcination product with phosphate LiH 2 PO 4 mixed with the aqueous solution of phosphate, stirred for 0.5 h, filtered, and dried at 120 °C to obtain a low-temperature calcined product after washing and coating, wherein the phosphate LiH 2 PO 4 The mass concentration of the aqueous solution is 10wt%;

[0052] (3) The low-temperature calcination product after washing and coating is calcined at a high temperature of 750 ° C for 15 hours to obtain a positive electrode material, wherein the general formula of the active material of the positive electrode material is LiNi 0.83 Co 0.11 Mn 0.0.06 O 2 .

Embodiment 2

[0054] (1) The positive electrode material precursor (Ni 0.83 Co 0.11 Mn 0.06 )(OH) 2 ), lithium salt Li 2 CO 3 and flux SrCO 3 Mixing and calcining at a low temperature of 500 ° C for 5 hours to obtain a low-temperature calcined product, wherein the mass ratio of the cathode material precursor, the lithium salt and the flux is 100:42:5;

[0055] (2) Combine the low-temperature calcination product with phosphate Li 2 HPO 4 Mixed with the aqueous solution of phosphate, stirred for 2 hours, filtered, and dried the filtered product at 115 °C to obtain a low-temperature calcined product after washing and coating, wherein the phosphate Li 2 HPO 4 The mass concentration of the aqueous solution is 0.1%;

[0056] (3) The low-temperature calcination product after washing and coating is calcined at a high temperature of 950 ° C for 5 hours to obtain a positive electrode material, wherein the general formula of the active material of the positive electrode material is LiNi 0.83...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com