Coated positive electrode material and preparation method and application thereof

A positive electrode material and coating technology, which is applied in the field of coated positive electrode materials and its preparation, can solve the problems of reducing the residual alkali on the surface of high-nickel positive electrode materials for lithium-ion batteries, the positive electrode materials are susceptible to moisture and water absorption, and the operation process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

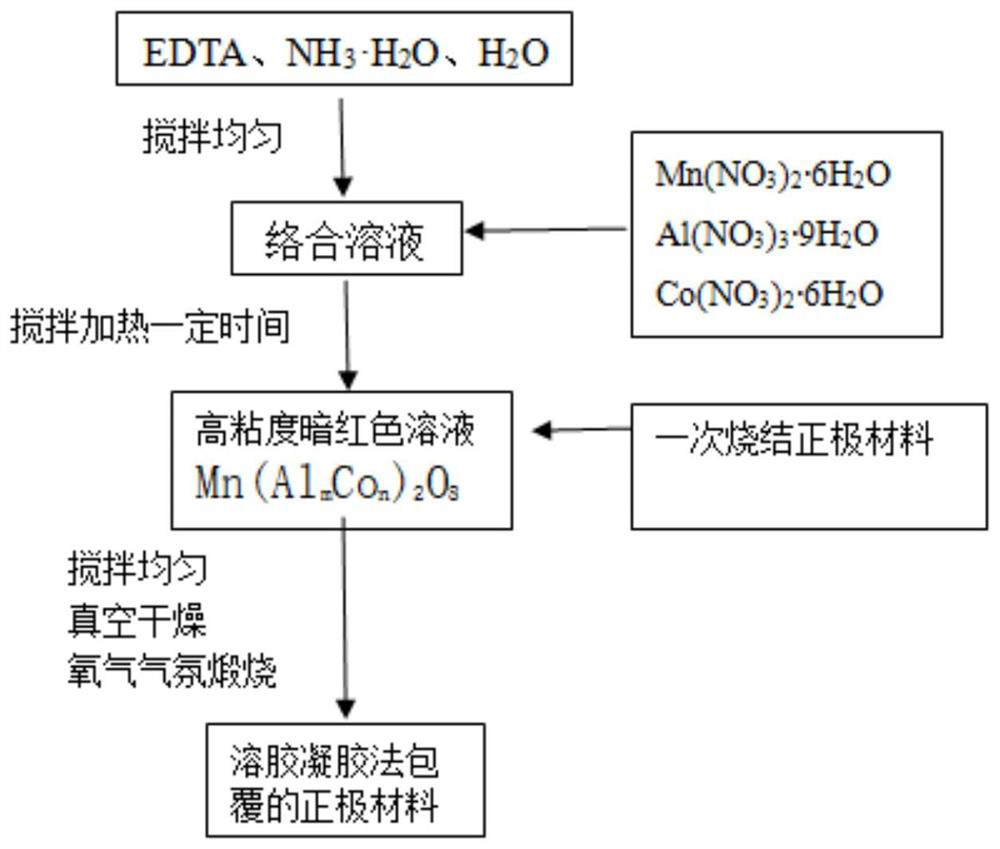

[0059] The preparation process flow chart of coated positive electrode material in the present invention is as follows figure 1 shown by figure 1 It can be seen that the preparation process includes:

[0060] Preparation of complexation solution: the complexation solution contains EDTA, NH 3 and water; among them, NH 3 Take NH 3 ·H 2 Form O added, and

[0061] Add coated metal source in complex solution, coated metal source comprises cobalt source (such as Co(NO 3 ) 2 ·6H 2 O), sources of manganese (such as Mn(NO 3 ) 2 ·6H 2 O) and aluminum sources (such as Al(NO 3 ) 3 9H 2 O); Stirring and heating for a certain hour; Obtain a dark red gel with high viscosity (comprising Mn(Al in the gel) m co n ) 2 o 8 )and

[0062] Add the positive electrode material (for example, the primary sintered positive electrode material obtained by mixing the precursor and the lithium source through primary sintering) to the above dark red gel, stir evenly, dry it in vacuum, and ca...

Embodiment 1

[0064] The preparation method of coated positive electrode material:

[0065] (1) The precursor Ni 0.88 co 0.06 mn 0.03 al 0.03 (OH) 2 Dry-mix with lithium hydroxide at a molar ratio of 1:1.03, perform primary sintering for 10 hours at 800°C in an oxygen atmosphere, cool, pulverize and sieve to obtain a primary sintered polycrystalline positive electrode material Li 1.03 Ni 0.88 co 0.06 mn 0.03 al 0.03 o 2 ;

[0066] (2) According to the molar ratio EDTA:NH 3 :H 2 O (deionized water)=0.06:1:5.5, the complexation solution of 100mL is prepared by mixing the three;

[0067] (3) 0.005mol Mn(NO 3 ) 2 ·6H 2 O, 0.01molAl(NO 3 ) 3 9H 2 O and 0.02mol Co(NO 3 ) 2 ·6H 2 O was added to the above complex solution, stirred to form a red solution, and then stirred and heated at 80°C for 5 hours to form a high-viscosity dark red gel Mn(AlCo 2 ) 2 o 8 ;

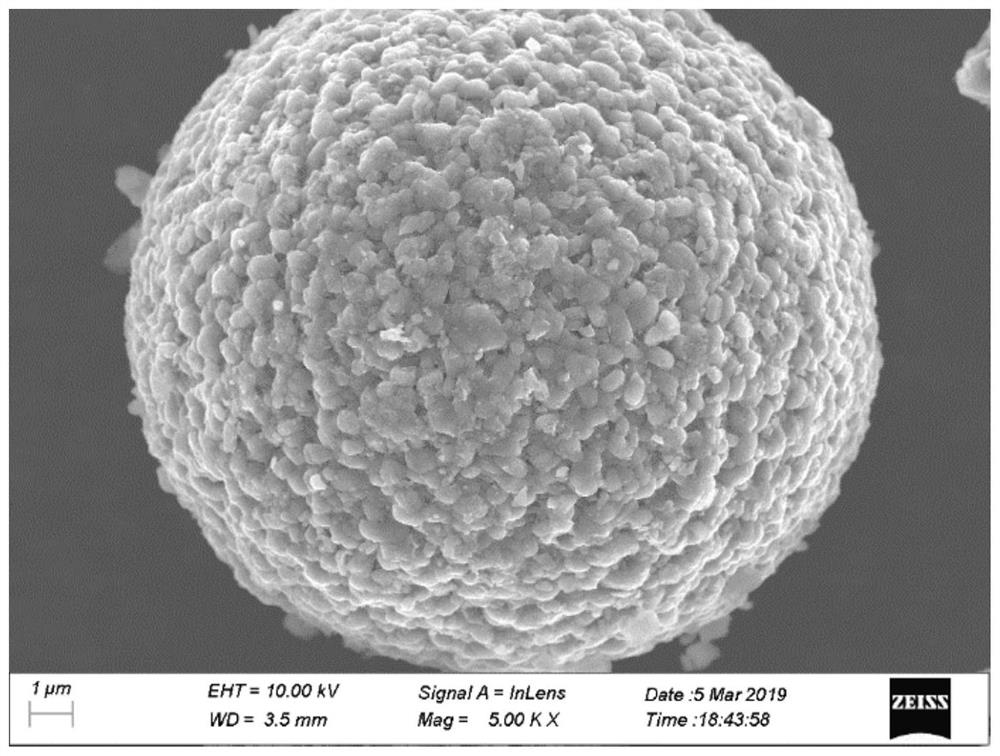

[0068] (4) Add 100 g of the polycrystalline positive electrode material obtained in step (1) to the above gel solut...

Embodiment 2

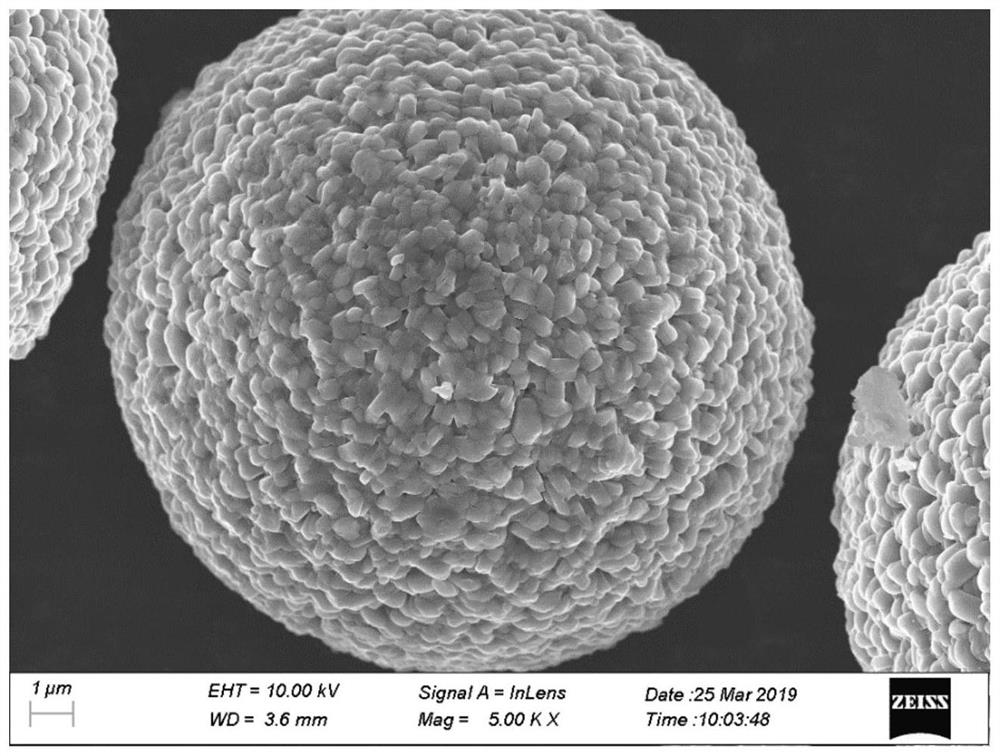

[0070] The difference between this embodiment and embodiment 1 is that the addition of manganese source, aluminum source and cobalt source is replaced by 0.003molMn (NO 3 ) 2 ·6H 2 O, 0.015molAl(NO 3 ) 3 9H 2 O and 0.015mol Co(NO 3 ) 2 ·6H 2 O; Other parameters and conditions are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com