Ternary positive electrode material and preparation method and application thereof

A technology of positive electrode materials and mixtures, which is applied in the field of lithium-ion batteries, can solve problems such as the inability to uniformly distribute doped metals, the inconspicuous improvement in the performance of ternary materials, and the uneven mixing of mechanical high-mixing, so as to achieve excellent electrochemical performance and improve The uniformity of doping and the effect of reducing the residual alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

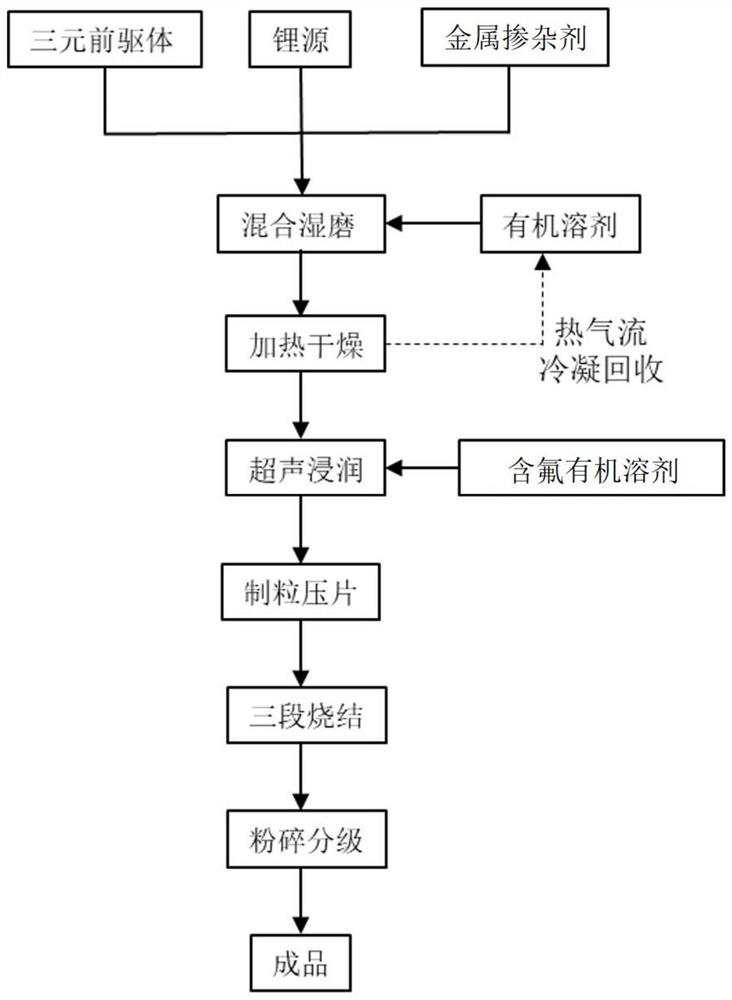

[0032] The first aspect of the invention discloses a method of preparing a three-dimensional positive material, such as figure 1 The following steps are included in the following steps:

[0033] The three-membered precursor, the lithium source, and the metal dopant are mixed, and the organic solvent is used as a dispersion medium, mixed wet mill, dry, and obtain a mixture;

[0034] The mixed particles were obtained by using a fluorine-containing organic solvent ultrasonic infiltration of the mixture.

[0035] The mixed particles were highly sintered, pulverized grading, and the three-stage positive electrode material was prepared by warming up the mixed particles.

[0036] The preparation method mixes the three-membered precursor, the lithium source, and the metal dopant, and the organic solvent is used as the dispersion medium, and the mixed wet mill is mixed. After drying, the metal element is uniformly distributed in the surface of the mixture, and can be dried by distillation....

Embodiment 1

[0050] Take 50g Ni 0.5 CO 0.20 Mn 0.3 (OH) 2 20.86G LI 2 CO 3 And 0.0425g MGCL 2 In the ball milling apparatus, the ball mill ratio of 20: 1, the rotary speed 300r / min ball milling was obtained by 100 ml of anhydrous methanol and 100 ml absolute ethanol, and the ball mill was 300r / min.

[0051] The ball grinding was dried at 120 ° C for 6 h, and the mixture was obtained;

[0052] The obtained mixture was mixed with 2.1270 g of a fluorine-containing organic solvent, and the supersonic frequency of 30 kHz is ultrasonically ultrasonic, wherein the fluorine-containing organic solvent is a mass solvent of mass than PVDF: NMAC = 1: 1;

[0053] The granulation of the ultrasonic infiltration was added to the granulator into a particle diameter of 10 mm, and the granulation pressure was 0.2 MPa;

[0054] The prepared particles were placed in the box furnace, warmed to 170 ° C at 1 ° C / min, and the temperature was warmed to 350 ° C at 3 ° C / min and the temperature was warmed by 5 ° ...

Embodiment 2

[0057] Take 50g Ni 0.6 CO 0.20 Mn 0.2 (OH) 2 , 23.60g LIOH Hi 2 O and 0.0425G MGCL 2 , 0.0434G ALCL 3 And 0.0312G ZrCl 4 In the joining the ball mill, 200 ml of diethyl ether as a ball mill, the spherium is 20: 1, the rotational speed 500r / min ball mill mill, obtaining a ball milling;

[0058] The ball grinding was dried at 120 ° C for 8 h and obtained a mixture;

[0059] The resulting mixture was mixed with 3.6858 g of a fluorine-containing organic solvent, and the ultrasonic frequency of 35 kHz is ultrasound for 2 h, wherein the fluorine-containing organic solvent is a mass solvent of mass than PVDF: DMF = 1: 1;

[0060] The material after ultrasonic infiltration was added to the granulator, granulated into a particle diameter of 5 mm, and the granulation pressure was 0.4 MPa;

[0061] The prepared particles were placed in the box furnace, warmed to 160 ° C at 3 ° C / min, and the temperature was warmed to 10 ° C at 1 ° C / min and the temperature was warmed by 3 ° C / min. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com