Dual-cladding 622-type Ni-Co-Mn ternary positive electrode material and preparation method thereof

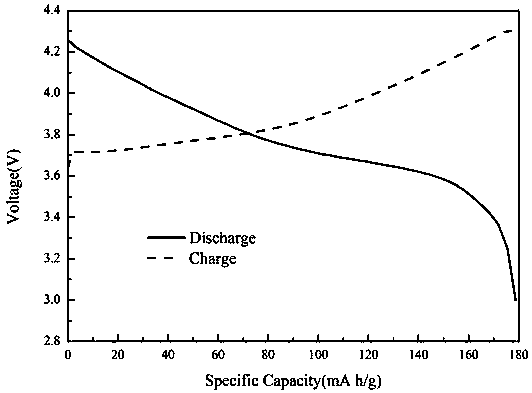

A positive electrode material, nickel-cobalt-manganese technology, applied in the field of lithium-ion battery positive electrode material manufacturing, can solve the problems of reduced manganese content, safety performance and cycle performance, and achieve good rate performance, high charge and discharge capacity, and excellent cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

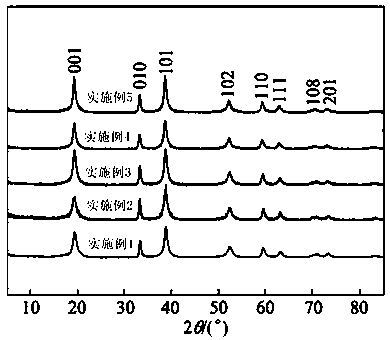

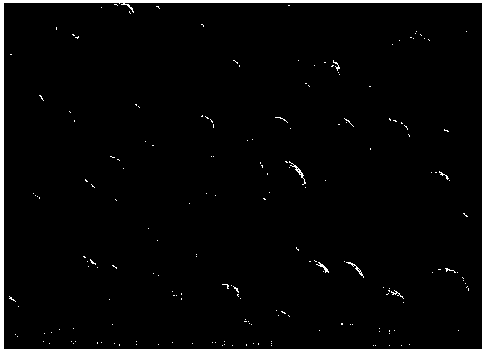

[0030] 0.03Al 2 o 3 0.03NaF LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation of cathode material

[0031] Lithium carbonate, Ni 0.6 co0.2 mn 0.2 (OH) 2 , aluminum oxide was added to the ball milling jar successively, put into the ball milling jar successively, and dry ball milled for 6 hours, wherein the ball milling jar was made of polytetrafluoroethylene material, the ball milling beads were made of zirconia, the particle size of the ball milling beads was 5mm, and the speed of the ball mill was 500 rad / min. The mass ratio of ball milling beads to mixture is 2:1. The above lithium carbonate and Ni 0.6 co 0.2 mn 0.2 (OH) 2 The molar ratio is 1.06:1 (because lithium will sublimate partly at high temperature, so lithium must be slightly excessive). The coating amount of alumina was 3%. At the end of the ball milling, the ball milling beads were separated to obtain a black powder. The powder is heat-treated in a muffle furnace: the temperature is raised to 700°C at 5°C / mi...

Embodiment 2

[0033] 0.06 Al 2 o 3 0.06NaF LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation of cathode material

[0034] Lithium carbonate, Ni 0.6 co 0.2 mn 0.2 (OH) 2 and aluminum oxide were successively added into the ball milling jar, put into the ball milling jar successively, and dry ball milled for 10 hours. Among them, the ball milling pot is made of polytetrafluoroethylene, the ball milling beads are made of zirconia, the particle size of the ball milling beads is 5 mm, and the speed of the ball mill is 500 rad / min. The mass ratio of ball milling beads to mixture is 2:1. The above lithium carbonate and Ni 0.6 co 0.2 mn 0.2 (OH) 2 The molar ratio is 1.06:1. The coating amount of alumina was 6%. At the end of the ball milling, the ball milling beads were separated to obtain a black powder. The powder is heat-treated in a muffle furnace: the temperature is raised to 700°C at 5°C / min at room temperature, and then kept at this temperature for 6 hours and then cooled naturally. A...

Embodiment 3

[0036] 0.09 Al 2 o 3 0.09NaF LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation of cathode material

[0037] Lithium carbonate, Ni 0.6 co 0.2 mn 0.2 (OH) 2 and aluminum oxide were successively added into the ball milling jar, put into the ball milling jar successively, and dry ball milled for 18 hours. Among them, the ball milling pot is made of polytetrafluoroethylene, the ball milling beads are made of zirconia, the particle size of the ball milling beads is 5 mm, and the speed of the ball mill is 500 rad / min. The mass ratio of ball milling beads to mixture is 2:1. The above lithium carbonate and Ni 0.6 co 0.2 mn 0.2 (OH) 2 The molar ratio is 1.06:1. The coating amount of alumina was 9%. At the end of the ball milling, the ball milling beads were separated to obtain a black powder. The powder is heat-treated in a muffle furnace: the temperature is raised to 700°C at 5°C / min at room temperature, and then kept at this temperature for 6 hours and then cooled naturally. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com