A kind of ruthenium-doped lithium vanadium phosphate cathode material and preparation method thereof

A lithium vanadium phosphate and cathode material technology, applied in chemical instruments and methods, battery electrodes, phosphorus compounds, etc., can solve the problems of low material specific energy, poor stability and safety, poor electronic conductivity, etc., and achieve simple preparation process and process easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

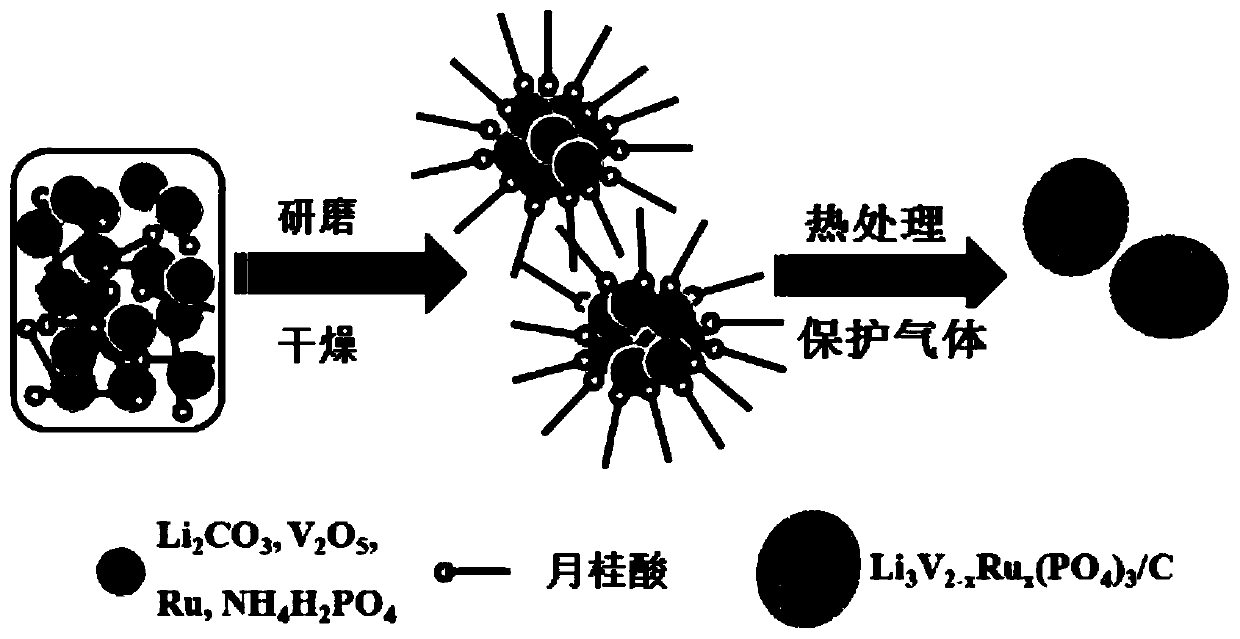

[0029] The preparation method of ruthenium-doped lithium vanadium phosphate cathode material, the steps are as follows:

[0030] (1) Li in stoichiometric ratio 2 CO 3 (0.03mol), V 2 o 5 (0.02mol), NH 4 h 2 PO 4 (0.06mol), RuCl 3 (0.0004mol) is added in the ball mill jar, namely Li:V:P:Ru molar ratio is 3:2:3:0.02;

[0031] (2) adding lauric acid (0.09mol), using absolute ethanol as a solvent, milling for 6 hours in a high-energy ball mill, making it uniformly mixed to obtain a slurry;

[0032] (3) drying the obtained slurry at 60° C. for 12 hours to obtain a precursor;

[0033] (4) Under a nitrogen atmosphere, the precursor was pretreated at 350°C for 4 hours and heat-treated at 750°C for 8 hours to obtain an electrode material. The reaction mechanism involved is figure 1 shown.

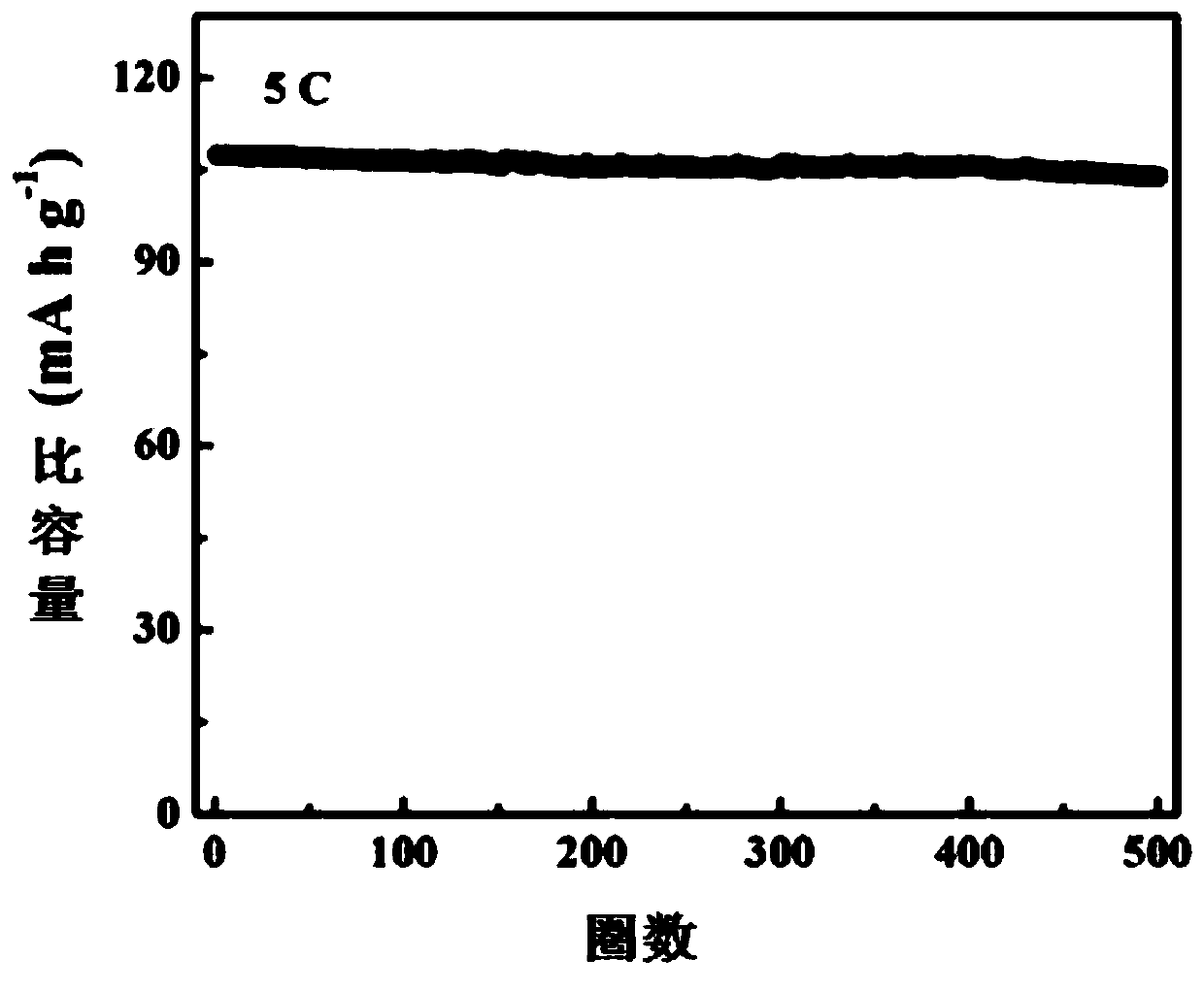

[0034] In this example 1, nanometer-sized electrode materials are obtained by means of the micelle action of the surfactant lauric acid, which shortens the diffusion distance of lithium io...

Embodiment 2

[0036] The preparation method of ruthenium-doped lithium vanadium phosphate cathode material, the steps are as follows:

[0037] (1) Reaction raw materials lithium acetate (0.06mol), ammonium metavanadate (0.0398mol), (NH 4 ) 2 HPO 4 (0.06mol), RuO 2 (0.0002mol) into the ball mill tank, that is, the Li:V:P:Ru molar ratio is 3:2:3:0.01;

[0038] (2) Add surfactant myristic acid (ratio of amount to lithium acetate substance is 3:3.5), use absolute ethanol as solvent, ball mill for 6 hours by high-energy ball mill, make it mix uniformly, obtain slurry;

[0039] (3) drying the slurry at 60° C. for 12 hours to obtain a precursor of ruthenium-doped lithium vanadium phosphate;

[0040] (4) Finally, the mixture was pretreated at 350° C. for 4 hours and heat-treated at 900° C. for 6 hours under an argon atmosphere to obtain an electrode material.

[0041] The samples in Example 2 were analyzed and tested for their morphology and electrochemical performance, and the results showed ...

Embodiment 3

[0043] The preparation method of ruthenium-doped lithium vanadium phosphate cathode material, the steps are as follows:

[0044] (1) Reaction raw material lithium hydroxide (0.06mol), V 2 o 5 (0.0196mol), H 3 PO 4 (0.06mol), RuCl 3 (0.0008mol) into the ball mill tank, that is, the molar ratio of Li:V:P:Ru is 3:2:3:0.04;

[0045] (2) According to the ratio of the amount of the surfactant oleic acid to the lithium hydroxide substance being 3:2.5, add a surfactant, use absolute ethanol as a solvent, and mill it with a high-energy ball mill for 6 hours to make it evenly mixed to obtain a slurry;

[0046] (3) drying at 60°C for 12 hours to obtain a precursor;

[0047] (4) The precursor is pretreated at 350° C. for 4 hours and heat-treated at 800° C. for 10 hours under a hydrogen atmosphere to obtain an electrode material.

[0048] The samples in Example 3 were analyzed and tested for their morphology and electrochemical properties, and the results showed that the prepared sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com