Carbon-coated negative electrode material, preparation method thereof and battery

A negative electrode material, carbon coating technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electronic conductivity and high rate performance, limit wide application, etc., to improve the intrinsic electronic conductivity, The effect of improving Li+ diffusion coefficient and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

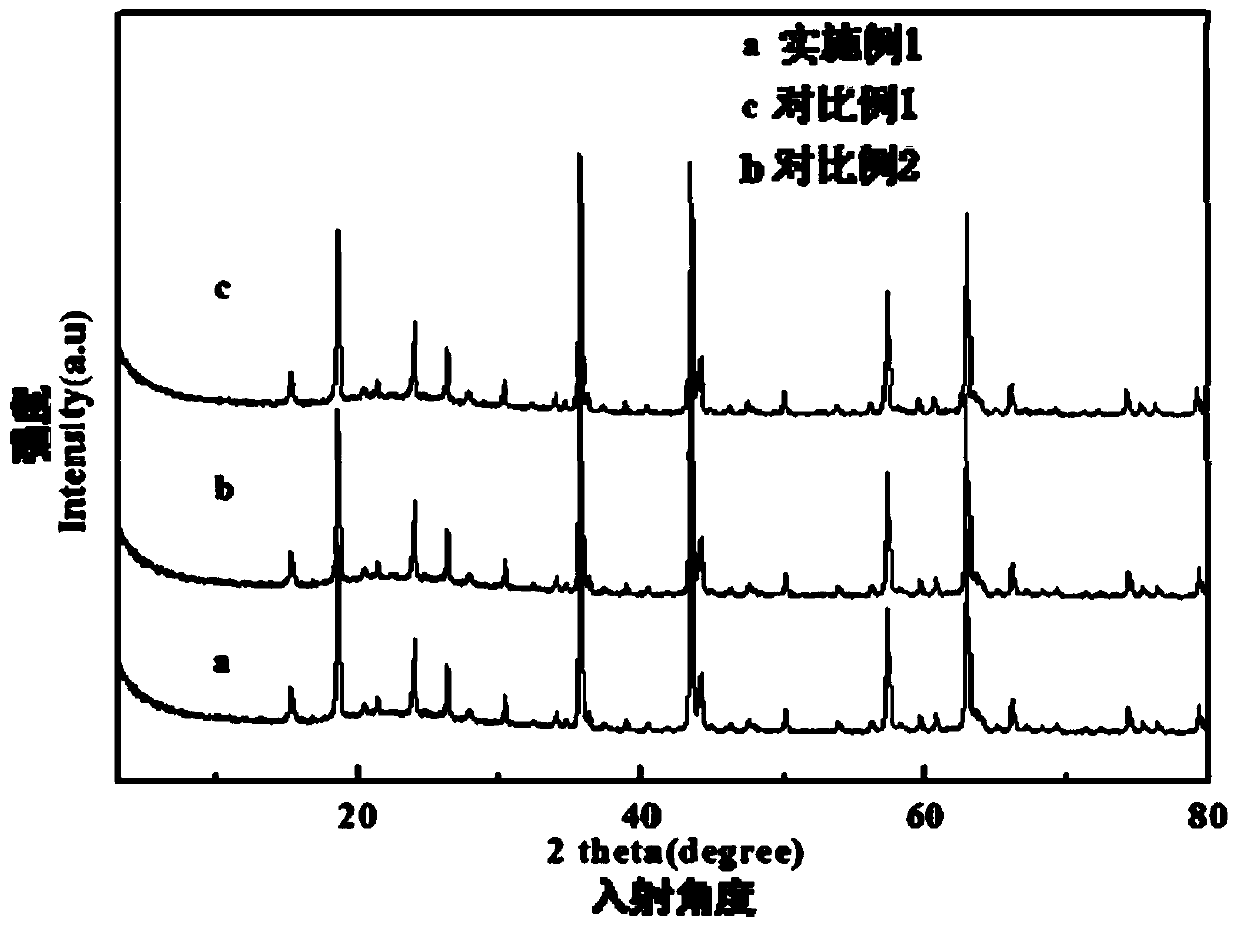

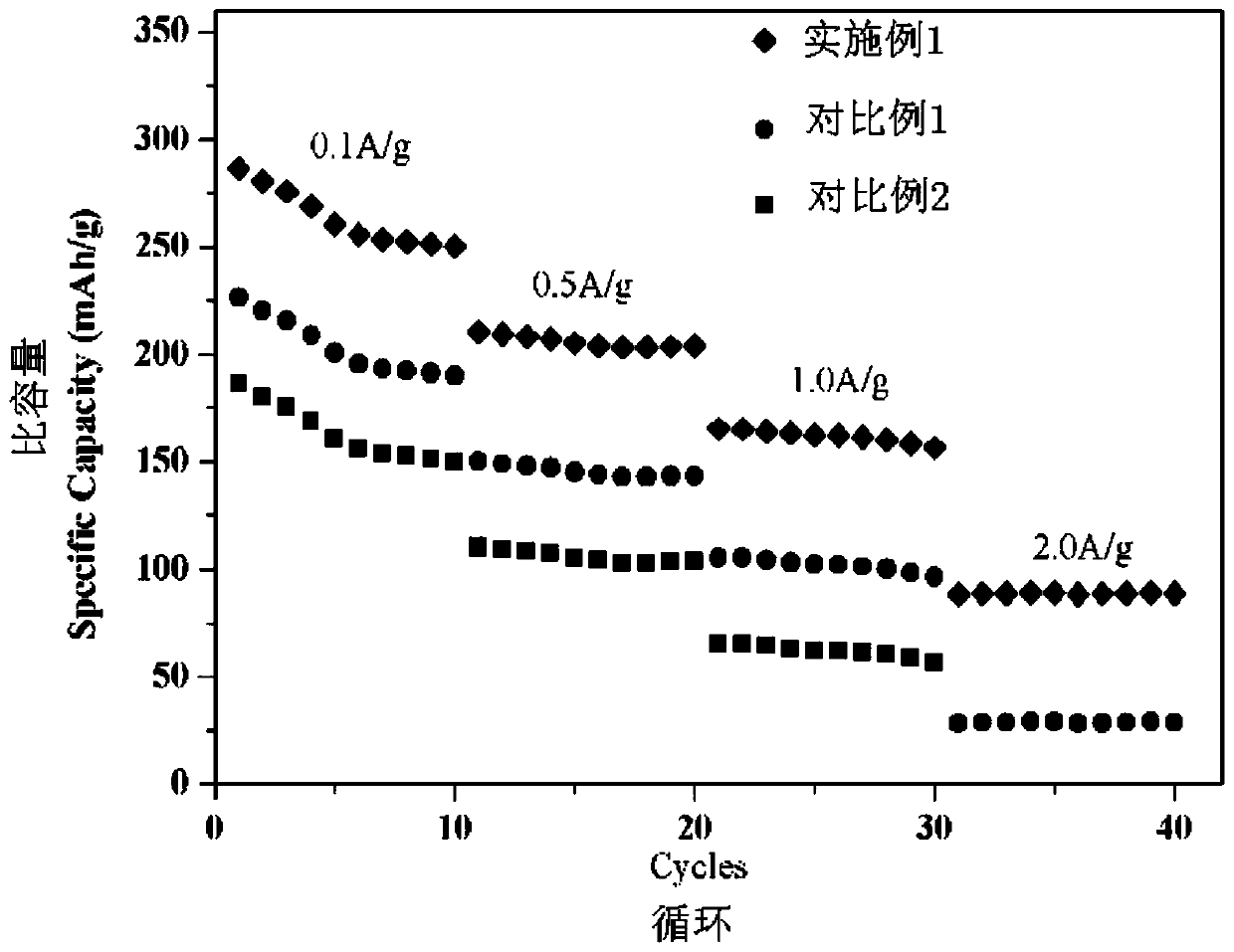

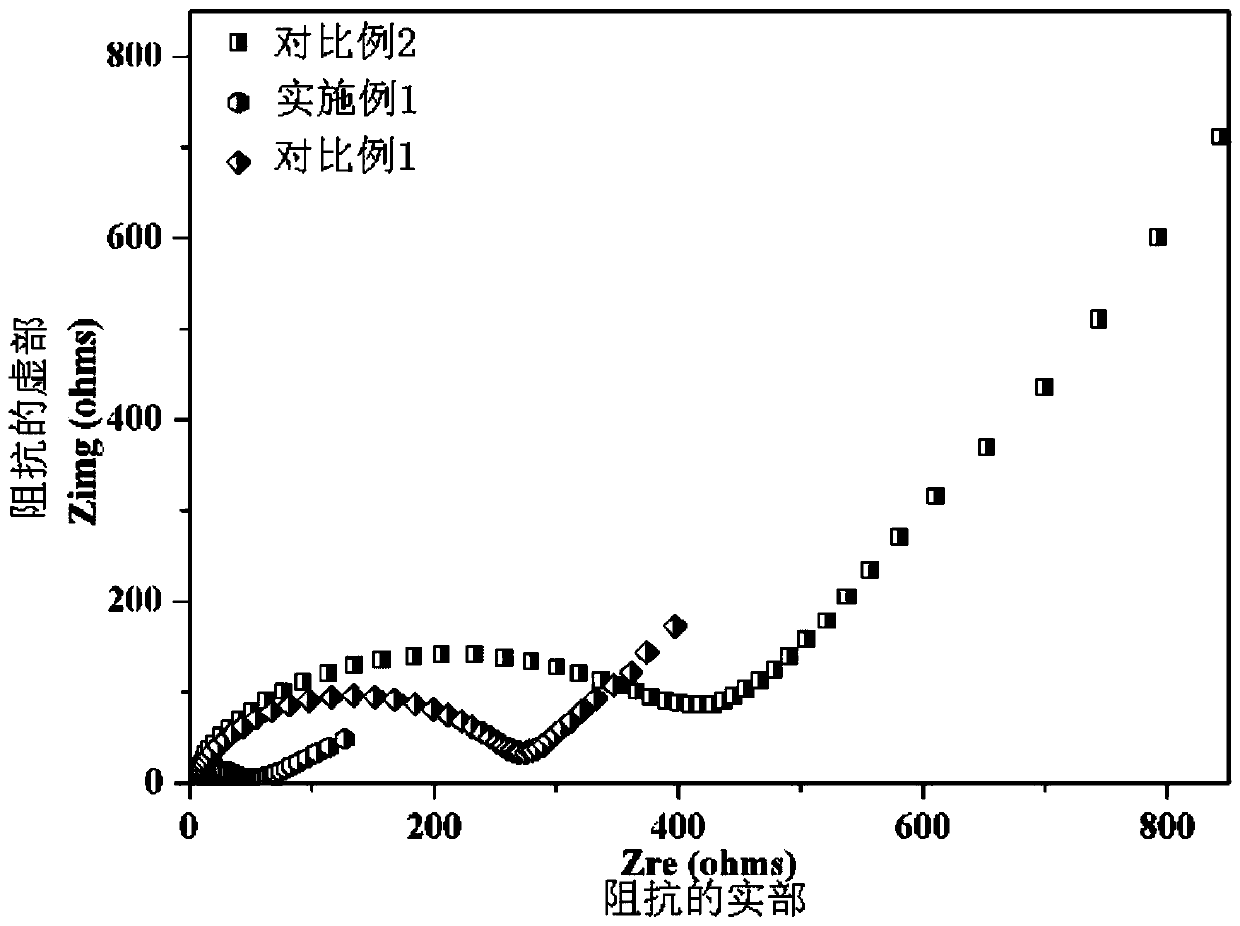

[0022] In the preparation method of the present invention, titanium dioxide, phosphoric acid, lithium source, metal element-containing salt, carbon source and water are subjected to step-by-step ultrasonic stirring to obtain a nano-scale homogeneous solution, and then the solid-liquid is separated and dried, and the ground powder is ground at a certain N 2 Under the condition of partial pressure, heat treatment is carried out to obtain the nano-titanium-based negative electrode material coated with nitrogen and phosphorus co-doped carbon. The preparation method does not need to adjust the acidity and alkalinity, nor does it need to adjust the temperature in the stirring process, thereby achieving the purpose of cost reduction and efficiency increase. The preparation method of the present invention is simple and feasible, and the intrinsic electronic conductivity and Li + The diffusion coefficient solves the problem of inherently low intrinsic conductivity of titanium-based ano...

Embodiment 1

[0031] 2.377g of anatase TiO 2 Mix the powder, 1g of sucrose and 0.3g of phosphoric acid, then add 60ml of deionized water and use an ultrasonic cleaner for 2 hours to disperse evenly, and then stir for 6 hours to obtain a uniformly mixed suspension A.

[0032] The lithium carbonate of 0.738g and the MgC of 2.1445g 2 o 4 2H 2 O was slowly added into the suspension A, first ultrasonically dispersed for 2 hours, and then stirred for 6 hours to obtain the suspension B.

[0033] The suspension B was suction-filtered to obtain a solid precursor, and then dried at 60°C for 8 hours, and then ground into a uniform powder.

[0034] The ground powder was heated at a rate of 2 °C / min to 700 °C for 1 hour, and then heated under N 2 The partial pressure is 80% of the total gas pressure (the other gas is Ar) and the temperature is raised to 800 ° C for 3 hours, and then cooled to 25 ° C to obtain a black nitrogen-phosphorus co-doped carbon-coated titanium-based lithium battery negative ...

Embodiment 2

[0045] The preparation method of this example is basically the same as that of Example 1, the only difference is that the quality of each component is different, anatase TiO 2 Powder is 2.1g, sucrose is 0.5g, phosphoric acid is 0.15g, lithium carbonate is 0.53g, MgC 2 o 4 2H 2 O is 1.5 g. The prepared negative electrode material has a reversible capacity of 253mAh / g in the first cycle at a current density of 0.1A / g, and a discharge specific capacity of 200mAh / g after 10 cycles. Under the current density, the discharge specific capacity can reach 170mAh / g, 150mAh / g and 70mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com