High-nickel lithium ion battery positive electrode material, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of material reversible capacity and cycle performance decline, sample cycle performance attenuation, and weak reactivity, etc., to alleviate Li atoms. Effect of surface diffusion, improvement of cycle performance and safety performance, slowing down of main element loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the high-nickel lithium-ion battery cathode material provided in this embodiment specifically includes the following steps:

[0054] (1) The metal oxide TiO is mixed by a fusion machine 2 Coated in layered high-nickel composite oxide cathode material LiNi 0.815 co 0.15 al 0.035 o 2 (x=0.815, M is Co, Al) surface, obtains coating electrode material; TiO 2 with LiNi 0.815 co 0.15 al 0.035 o 2 The mass ratio is 0.5:100;

[0055] (2) According to the mass ratio of water to coated electrode material is 6:1, add the coated electrode material obtained in step (1) into water and stir for 5 hours; then centrifuge at 5000rpm for 30min, and then in 150℃ It was dried for 10 hours, and the sample was denoted as S1.

Embodiment 2

[0057] The preparation method of the high-nickel lithium-ion battery cathode material provided in this embodiment specifically includes the following steps:

[0058] (1) The metal oxide SiO is mixed by a ball mill mixer 2 Coated in layered high-nickel composite oxide cathode material LiNi 0.88 co 0.085 al 0.035 o 2 (x=0.88, M is Co, Al) surface, obtains coating electrode material; SiO 2 with LiNi 0.88 co 0.085 al 0.035 o 2 The mass ratio is 1.5:100;

[0059] (2) According to the mass ratio of water to the coated electrode material of 8:1, add the coated electrode material obtained in step (1) into water and stir for 10 hours, then centrifuge at 4000rpm for 15min, and then put it under the condition of 250℃ Dry it for 15 hours, and the sample is denoted as S2.

Embodiment 3

[0061] The preparation method of the high-nickel lithium-ion battery cathode material provided in this embodiment specifically includes the following steps:

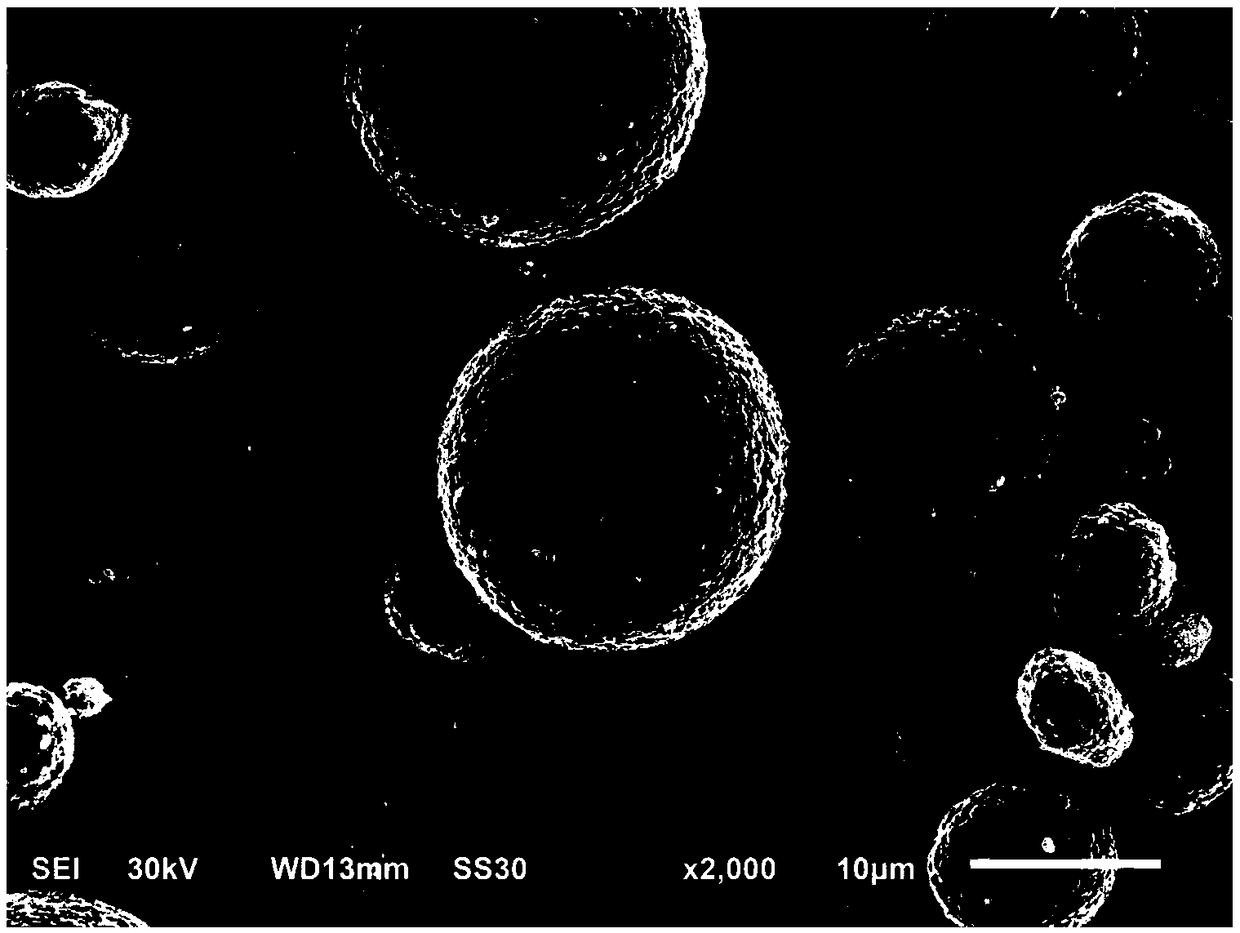

[0062] (1) First, the metal oxide SnO 2 and layered high-nickel composite oxide cathode material LiNi 0.83 co 0.11 mn 0.06 o 2 (x=0.83, M is Co, Mn) placed in the dispersant polyethylene glycol to form a suspension, SnO 2 with LiNi 0.8 co 0.15 al 0.05 o 2 The mass ratio of the suspension is 1:100; the solid-to-liquid ratio of the suspension slurry is 25%;

[0063] : Then the feed rate is controlled by a centrifugal spray dryer to be 60mL / min; the inlet temperature is 200 DEG C, and the outlet temperature is 120 DEG C, so that the SnO 2 Coated in layered high-nickel composite oxide cathode material LiNi 0.83 co 0.11 mn 0.06 o 2 Surface, obtain coated electrode material;

[0064] (2) According to the mass ratio of water to the coated electrode material of 4:1, add the coated electrode material obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com